Wing completion – Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 36

❏

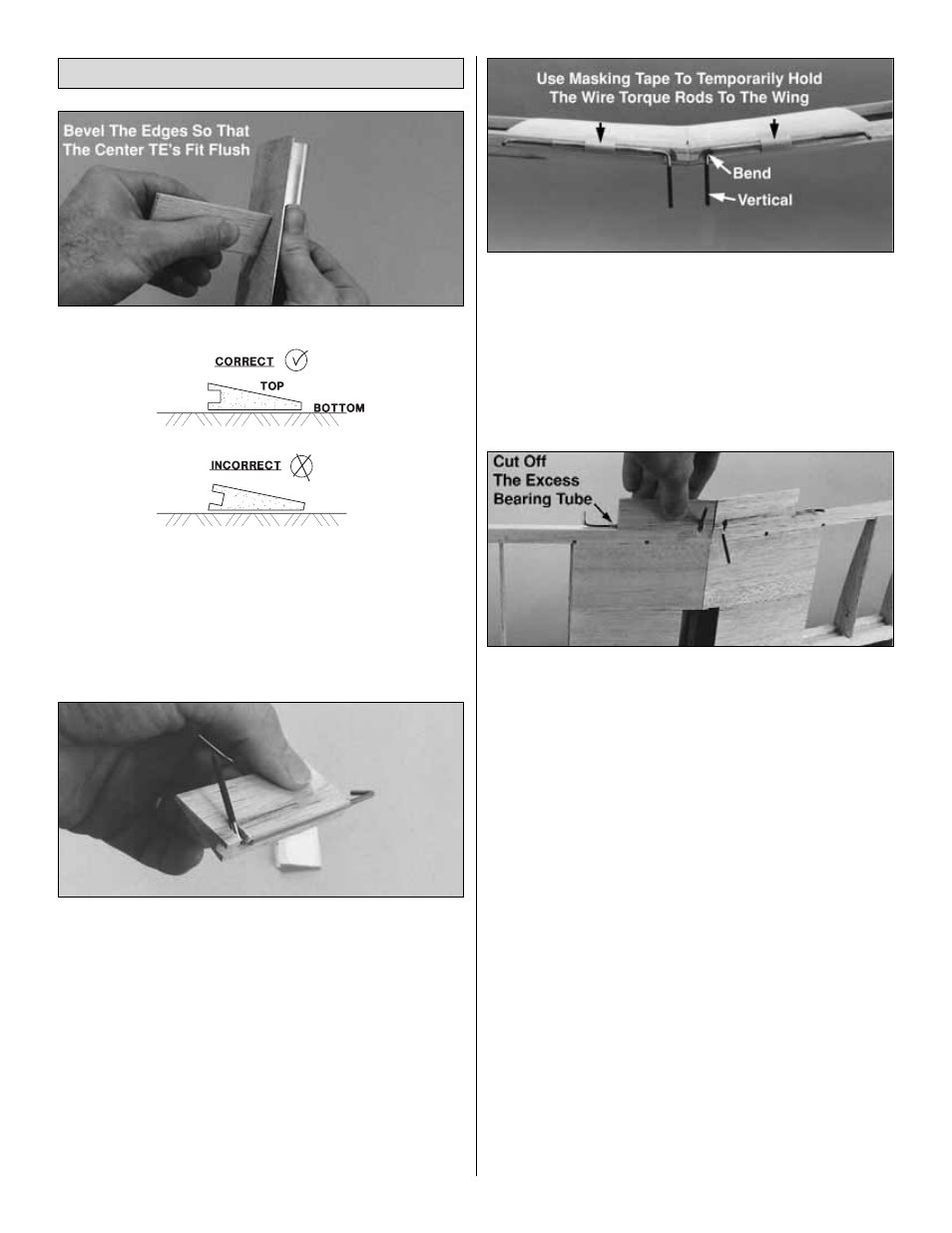

1. Reference the cross section on the wing plan so you

know which sides of the tapered and grooved wing center

trailing edges are the top and which sides are the bottom.

Position the wing center trailing edges on the wing and

sand a slight angle on the inboard end of each one so they

fit flush when matched to the dihedral angle. Lightly mark

the wing center TE’s as “R” and “L.”

❏

2. Position the wing center TE’s over the top view of the

plan with the root end aligned with the drawing. Mark the

location of the aileron torque rod exits and the outboard

ends of the wing center TE’s as shown on the plan. Cut a

notch in the bottom forward edge of each piece and cut

them to the length shown on the plan. Test fit the wire

torque rods.

❏

3. Hold the wing center TE’s against the aft edge of the

wing aligned with the wing’s centerline. Mark the torque rod

notches on the bottom of the wing, then cut the notches just

as you did for the wing center TE’s. The notches in the wing

TE don’t need to be nearly as deep as the notches in the

wing center TE’s.

❏

4. Use a pliers to bend the wire torque rods so the

threaded “ar m” is ver tical when the torque rods are

positioned on the trailing edge of the wing.

❏

5. With the torque rods in the wing center TE’s, position

the nylon bearing tubes so they do not restrict movement of

the torque rods. If part of the bearing tube protrudes from

the Wing center TE’s, trim it off (see the following photo).

❏

6. Position the Wing center TE’s with the torque rods on

the trailing edge of the wing. Make sure the notches align

and are deep enough to give the torque rods enough throw.

❏

7. Use coarse sandpaper to roughen the part of the

torque rods that fit into the ailerons and also the nylon

bearing tubes.

❏

8. With a toothpick, apply a small amount of petroleum

jelly (Vaseline, etc.) around the torque rods at each end of

the nylon tubes. This will help prevent glue from entering

the nylon tube.

❏

9. Apply 30-minute epoxy to the nylon tubes, staying

clear of the tubes ends. Insert the tubes into the grooves of

the Wing center TE’s. Use a paper towel to wipe off any

epoxy that squeezes out. Apply epoxy to the forward and

inboard edges of the Wing center TE’s, then glue them in

position as shown at step 6. Use masking tape to hold the

Wing center TE’s in position while the epoxy cures.

❏

10. Cut a 2-5/8" piece from each 30" aileron to make

the wing tip trailing edges. Glue the tip trailing edges to

the wing so that the end of the tip TE protrudes past the

wing tip by approximately 1/16". This will assure that the tip

TE is flush with the end of the wing after sanding.

Wing Completion

36