Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 16

❏

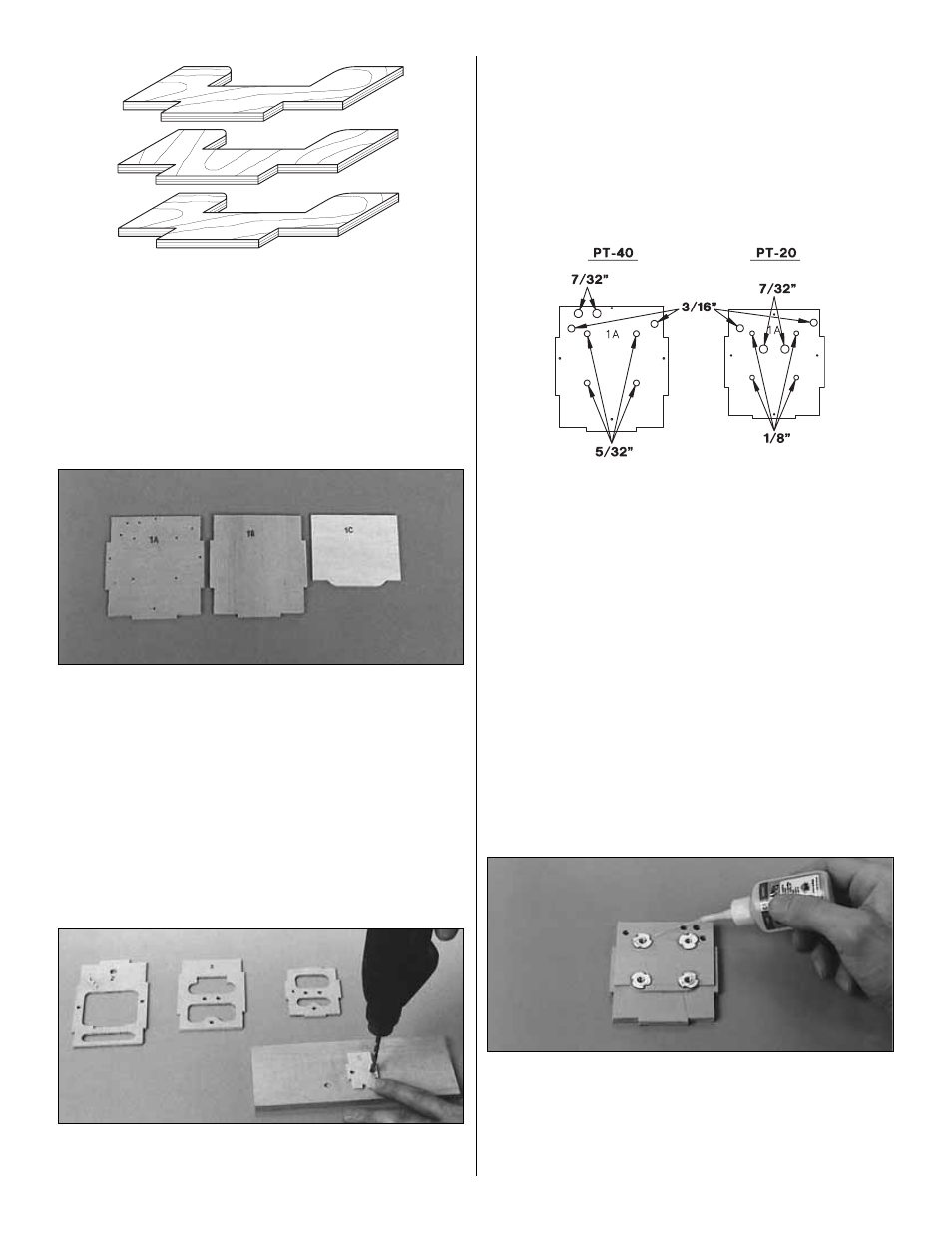

10. Notice that two pieces of the wing bolt plate

assembly have grain running in one direction while the third

piece has grain running opposite to the first two. The odd

one goes in the center of the “sandwich.” Mix about 1/4 oz.

of 30-minute epoxy and glue the bolt plates together as

shown (the extra epoxy will be used in the next step). This

assembly must be clamped together with C-clamps or

weighted down while the epoxy cures. If you use weights,

be sure the pieces do not slide and shift when you add

the weights.

❏

11. Use the remaining 30-minute epoxy to glue F-1A,

F-1B and F-1C together. Be sure that F-1A (the one with

the punch marks) is on top of the stack with the punch

marks facing outward, the locking tabs are aligned, and

that F-1C is flush with the top edge of the assembly (see

the fuse plan). This assembly must be held together with

clamps, or weighted down while the epoxy cures. Note: If

the three formers are wrapped, simply clamping them

together may not necessarily “cancel out” the warps. It is

best to clamp the assembly over waxed paper to a flat

board or table. Allow the epoxy to fully cure before

removing the clamps.

❏

12. Position the die-cut 1/8" plywood formers F-2

through F-5 over a piece of scrap wood, then drill a 3/16"

hole through each of the punch marks (former F-4 on the

PT-20 is balsa). Do not drill the F-1 assembly during this

step. Note: When punching out former F-2 from the die

sheet, don’t accidentally throw away the plywood hatch

retainer as it may be easily mistaken for scrap. Refer to the

die drawings.

❏

13. Refer to the sketch, then drill two 3/16" pushrod tube

holes through the firewall where indicated. Change your bit

size to 7/32" (or 15/64" for perfection) and drill the two fuel

tube holes where indicated. Finally, drill four 5/32" holes

(1/8" if you’re building the PT-20) for the engine mount blind

nuts. Note: The remaining four punch marks around the

perimeter of the firewall could be used for locating the

center of the firewall should you choose to use a different

engine mount.

❏

14. Clean up any slivers from around the holes you

drilled and also the edges of the formers with a bar sander

and 220-grit sandpaper.

❏

15. Press a 6-32 blind nut (4-40 if you’re building the

PT-20) into one of the holes in the back of the firewall

(F-1C), then tap it gently with a hammer until it is fully

seated. Put a few drops of thin CA on the outer edge of the

flange to secure the blind nut. Install the remaining three

blind nuts the same way.

16