Calibration procedure – Cannon Instrument miniPV-X User Manual

Page 38

CANNON

®

miniPV-Series Automatic Viscometer with VISCPRO

®

Instruction & Operation Manual

Version 1.a— January, 2011;

CANNON

®

Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

32

NOTES

The software allows the operator to manually change the constants if neces-

sary to more closely match the known viscosities of the standards.

A separate calibration must be performed for each temperature at which

samples will be tested.

Calibration procedure

1. Assemble a group of

CANNON

®

standard oils with known kine-

matic viscosities for calibration. Use at least two different standards

for each bulb. Refer to the following table when choosing the appro-

priate standards.

e

l

b

a

T

n

o

i

t

c

e

l

e

S

l

i

O

n

o

i

t

a

r

b

i

l

a

C

1

B

L

U

B

G

N

I

M

I

T

)

1

-

2

s

r

o

t

s

i

m

r

e

h

t

(

2

B

L

U

B

G

N

I

M

I

T

)

1

-

3

s

r

o

t

s

i

m

r

e

h

t

(

t

i

m

il

t

S

c

r

e

w

o

l

x

0

0

1

-

0

1

t

i

m

il

t

S

c

r

e

w

o

l

x

0

1

-

1

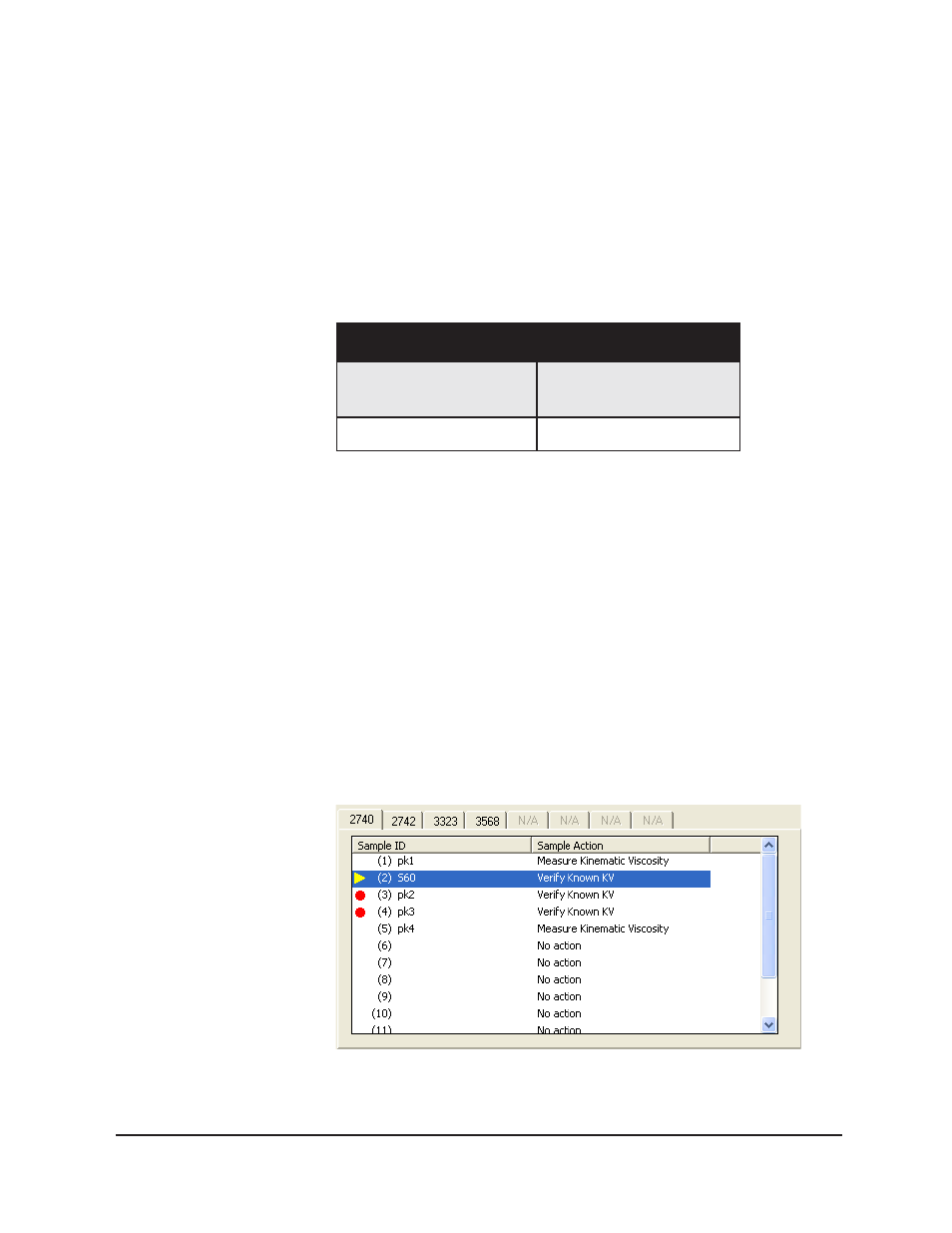

2. Complete sample ID data entry for each standard.

3. After entering each sample ID, click on the highlighted ID entry using

the RIGHT mouse button (or press

5). Then select

Verify Known

KV

from the popup window. The

Viscosity Action

window will

appear.

4. Enter the viscosity (in centistokes) for each sample from the standard

bottle, along with other desired configuration settings; then click

OK

.

NOTE

If a check standard viscosity has NOT been entered (or if the default

viscosity value of 1.000 has not been accepted by the user), a yellow arrow

(current sample) or red circle caution symbol will appear to the left of the

sample ID: