0 batching, Batching, Agg cem – Rice Lake CB-2 Concrete Batch Controller Version 2.0 User Manual

Page 60

56

Installation/Operation Manual

8.0

Batching

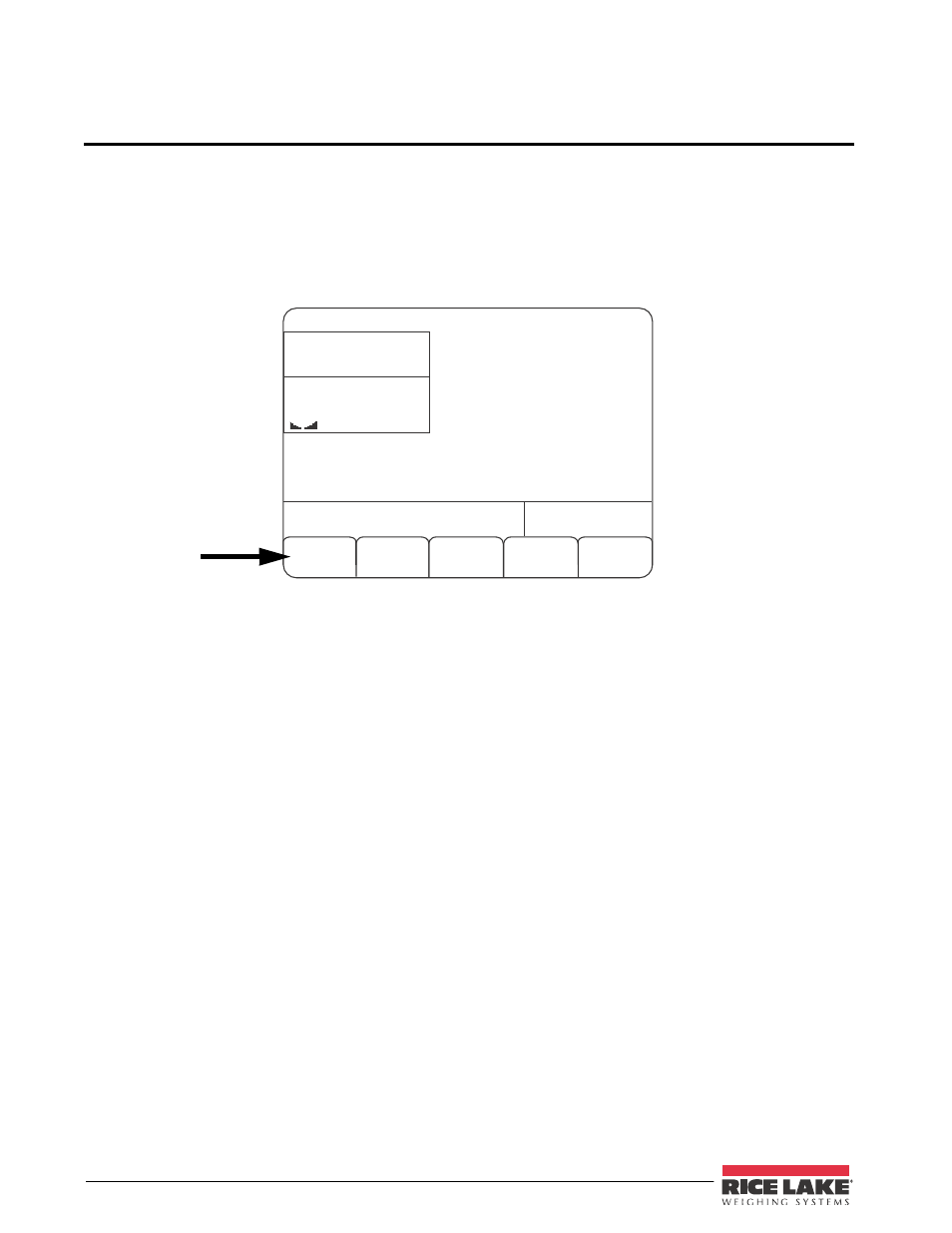

There are two basic modes of operation. The simplest is a load-based approach when the operator enters only a

mix, truck, and load quantity. This method is best when the CB-2 is not used for generating billable tickets or

tracking at the order level. In contrast, if order-based loading is selected, each order is entered in the CB-2 as the

order is taken. Order information that may be entered in the CB-2 includes: Customer ID, total ordered amount,

mix design, when required, slump, delivery address, special instructions, and job IDs.

In load based batching, the

Prepare Load

softkey appears on the main menu of softkeys.

05/30/2013

08:13AM

Admin Menu

CB-2 2 Scale

Prepare

Load

Utilities

SCALE 1

EZ-Change

Criticals

AGG

CEM

Scale

Scale

#1

#2

lb Gross

lb Gross

00

0

Figure 8-1. Prepare Load Softkey

Assuming that all the setup and configuration procedures have been accomplished successfully, a load can be

started by following the instructions listed below.

1. Press the

Prepare Load

softkey on the 920i display.

2. At the

Mix Design ID/Code

prompt, enter the numeric mix ID or alphanumeric code and press the

enter

key.

The mix design database is first checked for a matching mix code. If no matching mix code is found, the

mix database is searched for a matching mix ID. If neither is found, the following message appears,

Mix

ID/Code not found

, and the prompt is closed. The operator then needs to press the

Prepare Load

softkey

again after figuring out the correct mix code or ID.

3. After a valid mix code or ID has been found, the operator is then prompted with

Truck #

. Enter the number

of the truck that will be loaded. The truck database is searched for a matching truck ID. If found, the

capacity, loading ratio, and driver name data are retrieved and used in the loading process. If not, the

truck number is just printed on the ticket.

4. Next, at the

Quantity

prompt, enter the load quantity. The value entered must meet the following criteria:

•

The quantity must be able to fit into the selected truck as configured in the capacity field of the truck

database, provided the entered truck ID was found in the database.

•

The quantity entered may be larger than the maximum plant capacity (see application parameters -

batching limits - max plant capacity setting), provided split-batching is enabled (see application

parameters - batching preferences - split batching allowed setting).

•

The quantity entered must be larger than the minimum plant capacity (see application parameters -

batching limits - min. plant capacity setting).

After these three critical values have been verified, the message

Preparing...

will appear while the load and batch

calculations are being made. If no problems were encountered with the plant configuration, database data, and

calculations, the

preview load

screen is displayed.

5. Once all of these parameters are successfully entered into the CB-2 the

Preview Load

screen is displayed.

The

Preview Load

screen is automatically displayed so the user can:

•

Confirm the mix design, quantity, and target values for each material in the mix.