05 frame fab – Oldcastle BuildingEnvelope Reliance-IG SS User Manual

Page 8

5

R E L I A N C E - I G S S I N S T A L L A T I O N M A N U A L

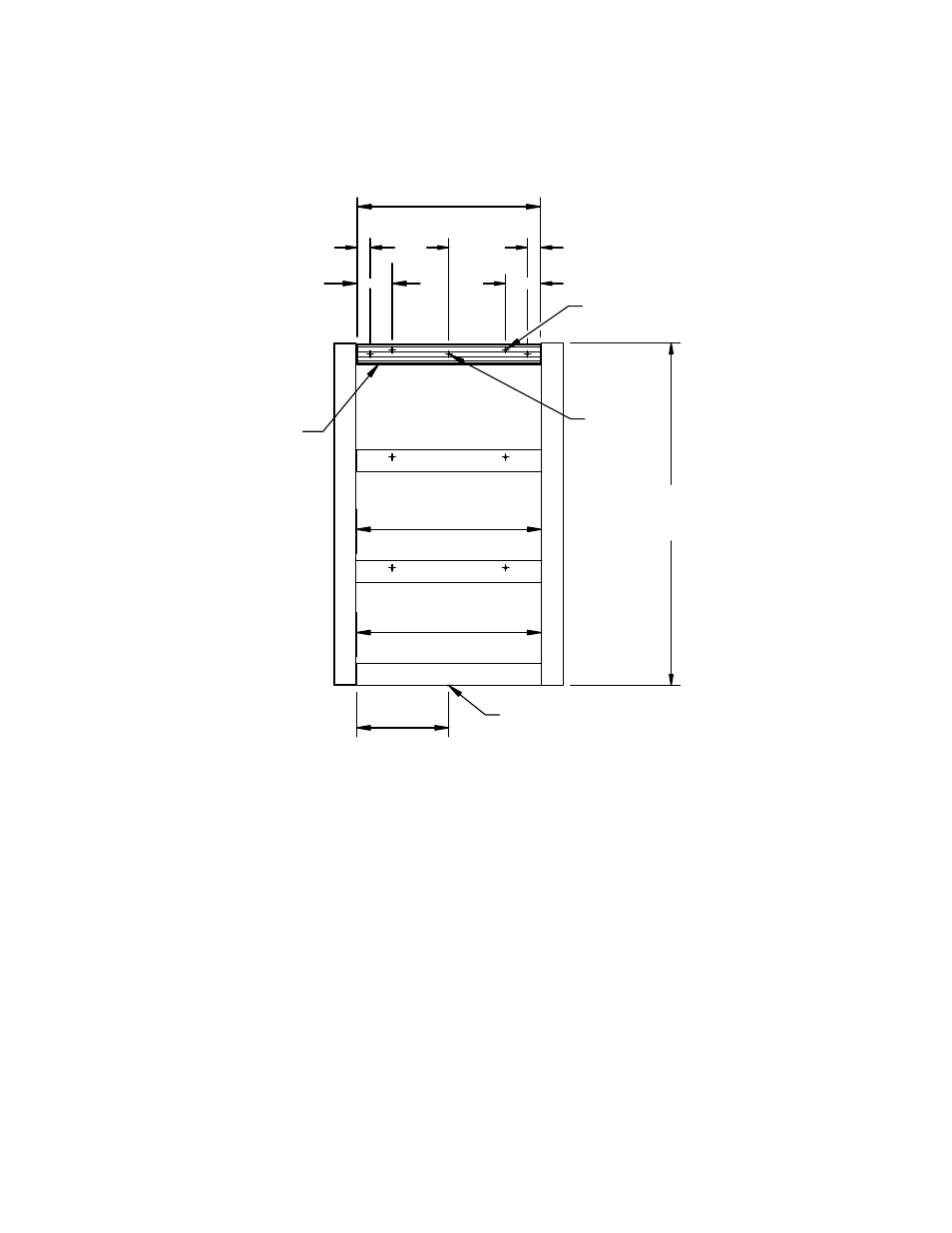

typ.

Quarter points

D.L.O.

Horizontal

Midpoint

5/16" dia. weep hole

(bottom leg of face cover)

Typical Face Cover

5/16" dia. weep hole

9"

1 1/2"

1 1/2"

&.1OKPWU

D.L.O. minus 1/4"

Quarter points

Vertical &

Vertical Face =

FRAME HEIGHT

V

er

tic

al

F

ac

e

Pressure Plate

Factory

punched

holes

FIGURE 1

Material Fabrication Guide

1.3 Fabricate vertical mullions for horizontal members with EZ Punch tooling or DJ-108

drill jig. See FIGURE 2,page 6 for hole locations. Use 'F' drill (.257 dia.) for assembly screws.

Prep for head and sill will be drilled by aligning drill jig with ends of mullions. Prep at

intermediate horizontals, mark line at top of horizontal and align drill jig with that line

as shown in FIGURE 2, page 6. Use DJ-105 for fabrication of WW-542 exterior glazed

horizontal, drill all four holes.

1.4 Drill 5/16" dia. weep holes at 1/4 points in horizontal and sill members as shown in

FIGURE 3, page 7. Where incidental water control is required, drill one 5/16" diameter

weep hole at mid-lite of head member. Locate HP-1004 baffle and snap SPW-295 baffle

retainer behind weep hole. See FIGURE 3, page 7.

1.5 Drill (1) 5/16" dia. weep hole at the bottom of each horizontal face cover at the centerline

of the D.L.O. SEE FIGURE 4, page 7. NOTE: For SSG applications, face covers

typically run across SSG mullions, so there will be multiple holes in each horizontal

face cover. Maximum length of horizontal face covers at SSG applications should

be 20 feet.

Optional Exterior

Glazed Horizontal

FRAME FABRICATION