11 frame assy – Oldcastle BuildingEnvelope Reliance-IG SS User Manual

Page 14

11

R E L I A N C E - I G S S I N S T A L L A T I O N M A N U A L

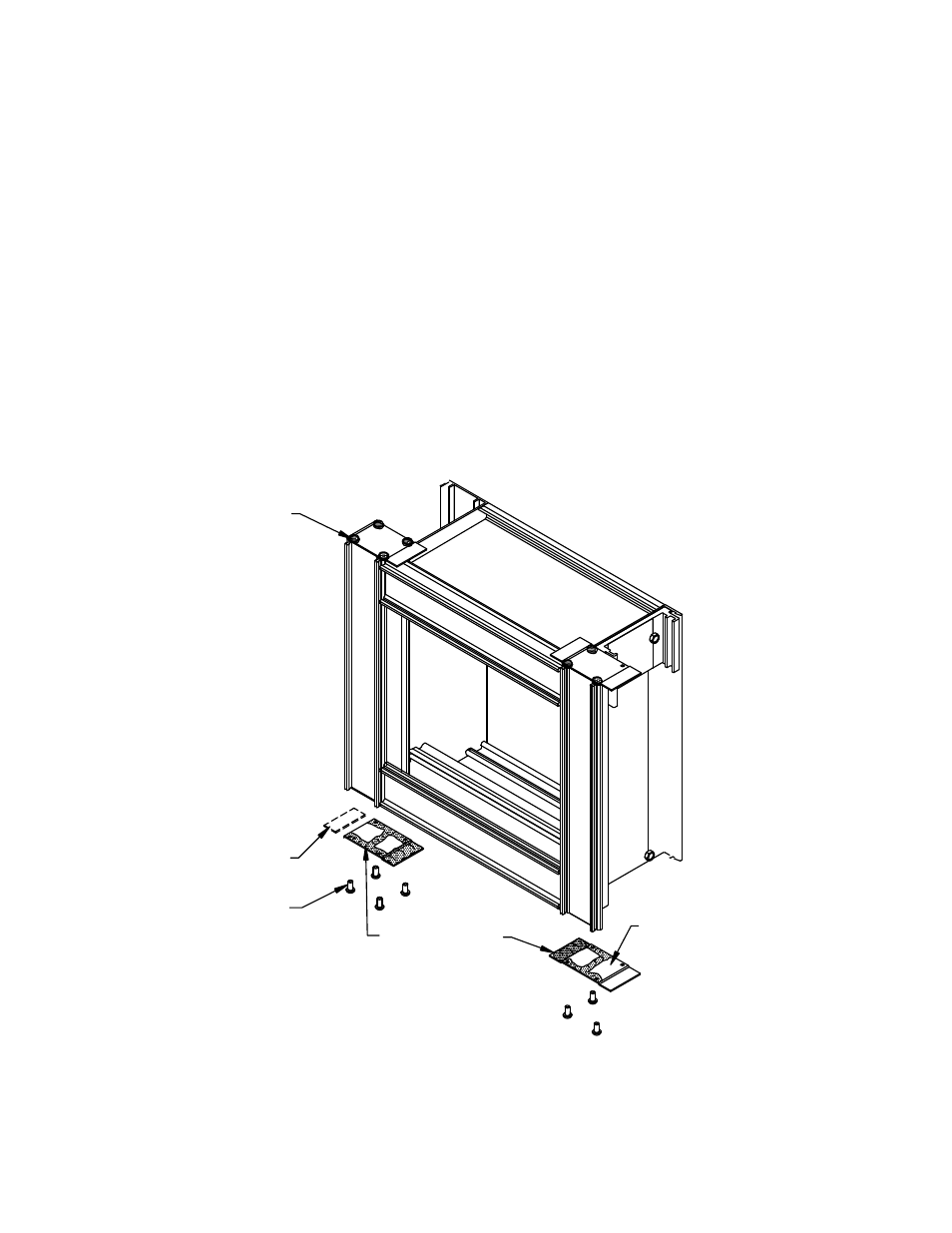

2.7 After units are assembled. Install mull caps to each end of vertical mullions and jambs. IW-325-01 mull

cap will be bed in sealant and attached to mullion with FS-320 drive screws. Sealant must be tooled

around inside of glazing pocket and on mating surfaces between mull cap, head/sill and verticals. SEE

FIGURE 9 . Note: SSG mullions will not use mull caps. Bridges will be field installed at SSG verticals as

noted on sheet 30.

2.8 Isolator clips for face cap installation may be installed in the shop or field. If installed in shop care must

be taken in transporting units not to break or disengage clips from mullion. Clips are installed by starting

one end and rotating into position. Clips will snap over clip stem. Clip tool, part # ICW-FP-74 may be

used to speed up installation process. GP-141 baffle clips must be installed over weep holes at all

intermediate horizontals. ICW-12 clips are to be installed at 12" on center and staggered to

prevent bowing of face cap at clips. SEE FIGURE 10, page 12.

.

IW-325 Mull Cap

IW-325 Mull Cap

Trim leg for jamb

at head and sill

Bed mull cap in

sealant and tool

sealant at mullion.

FS-320 "U" Drive

FIGURE 9

Mull Cap Installation

(SSG mullions do not use mull caps)

Cap seal all

fastener heads

FRAME ASSEMBLY