20 zone plug install – Oldcastle BuildingEnvelope Reliance-IG SS User Manual

Page 23

20

R E L I A N C E - I G S S I N S T A L L A T I O N M A N U A L

3.13 Step 1. Seal gasket races and adaptor tracks. Proper sealant of these tracks is critical to insure water

does not drain through the tracks into glazing pocket below or penetrate interior of building at glass

stops.SEE FIGURE 22, page 21.

3.14 Step 2. Place bead of sealant around glazing pocket at location where zone plug will be located prior to

inserted into pocket. Also lay bead of sealant across top of stem of horizontal. Place ICR-107-01 zone

plug into pocket so that it may rotate over stem and snap into position. SEE FIGURE 23, page 22.

3.15 Apply additional sealant around top of zone plug at mullion and horizontal. Marry sealant with sealant

previously applied into gasket races and tracks.

3.16 Step 3. Tool sealant between zone plug, mullion and horizontal to insure a proper seal.

SEE FIGURE 24, page 22.

3.17 Once sealant is cured. It is recommended that weep holes in horzontal be plugged and each horizontal

pocket filled with water. If water leaks through at any connection, drain pocket, dry and reseal. Then

repeat until leaks have been resolved.

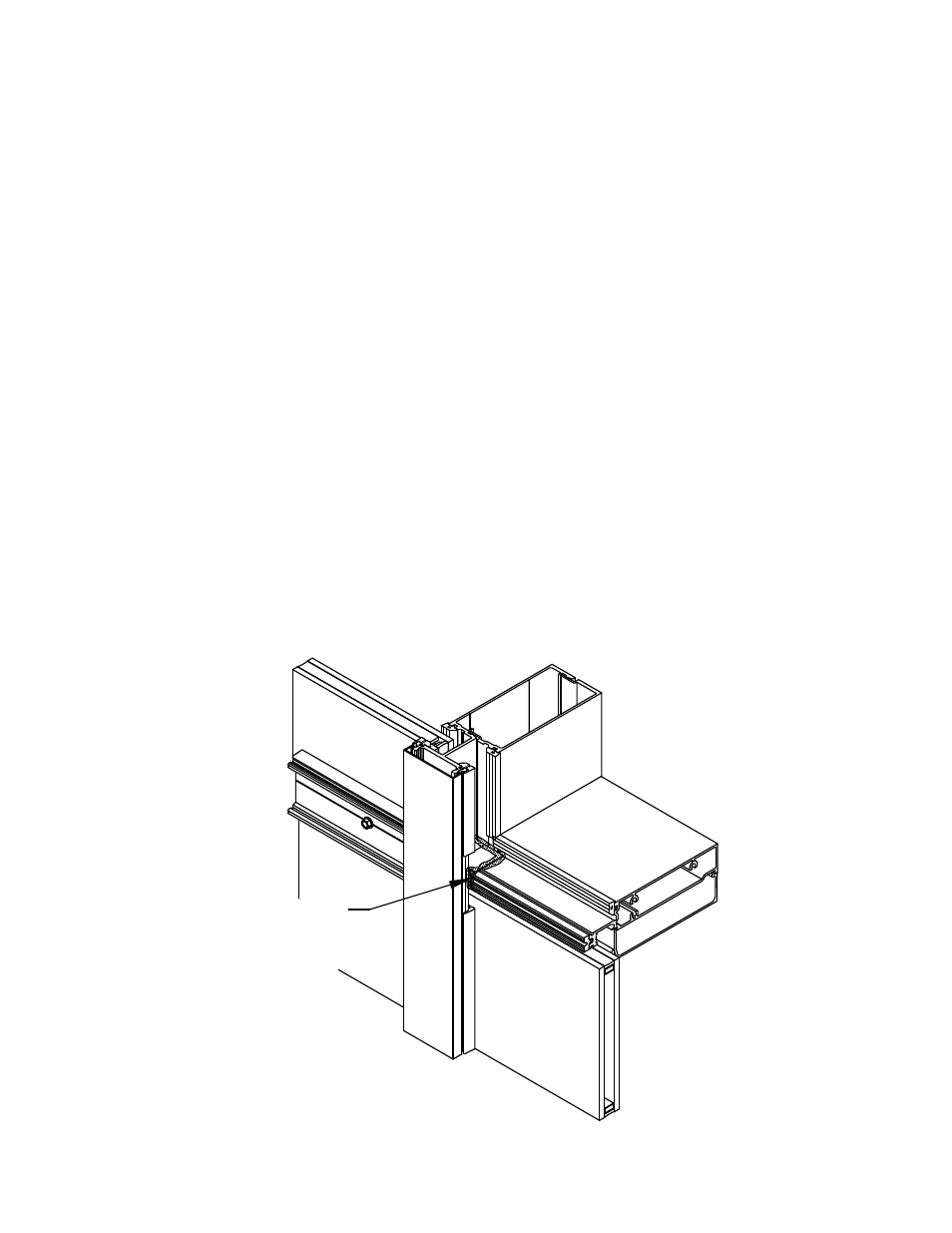

3.18 Exterior glazed horizontal will require sealant be applied along face of zone plug and horizontal stem

prior to installing pressure plate. Since water testing of these area is not possible, special care need to

be taken to seal the zone plug to prevent leaks. See FIGURE 21

FIGURE 21

Exterior Glazed Zone Installation

ZONE PLUG INSTALLATION

Add sealant between

GP-107, zone plug and

mullion prior to installing

pressure plate.