5 verification of the primary diode (d1) – Tweco 400 MST Arc Master User Manual

Page 50

400MST

9

ADVANCED TROUBLESHOOTING

9 – 13

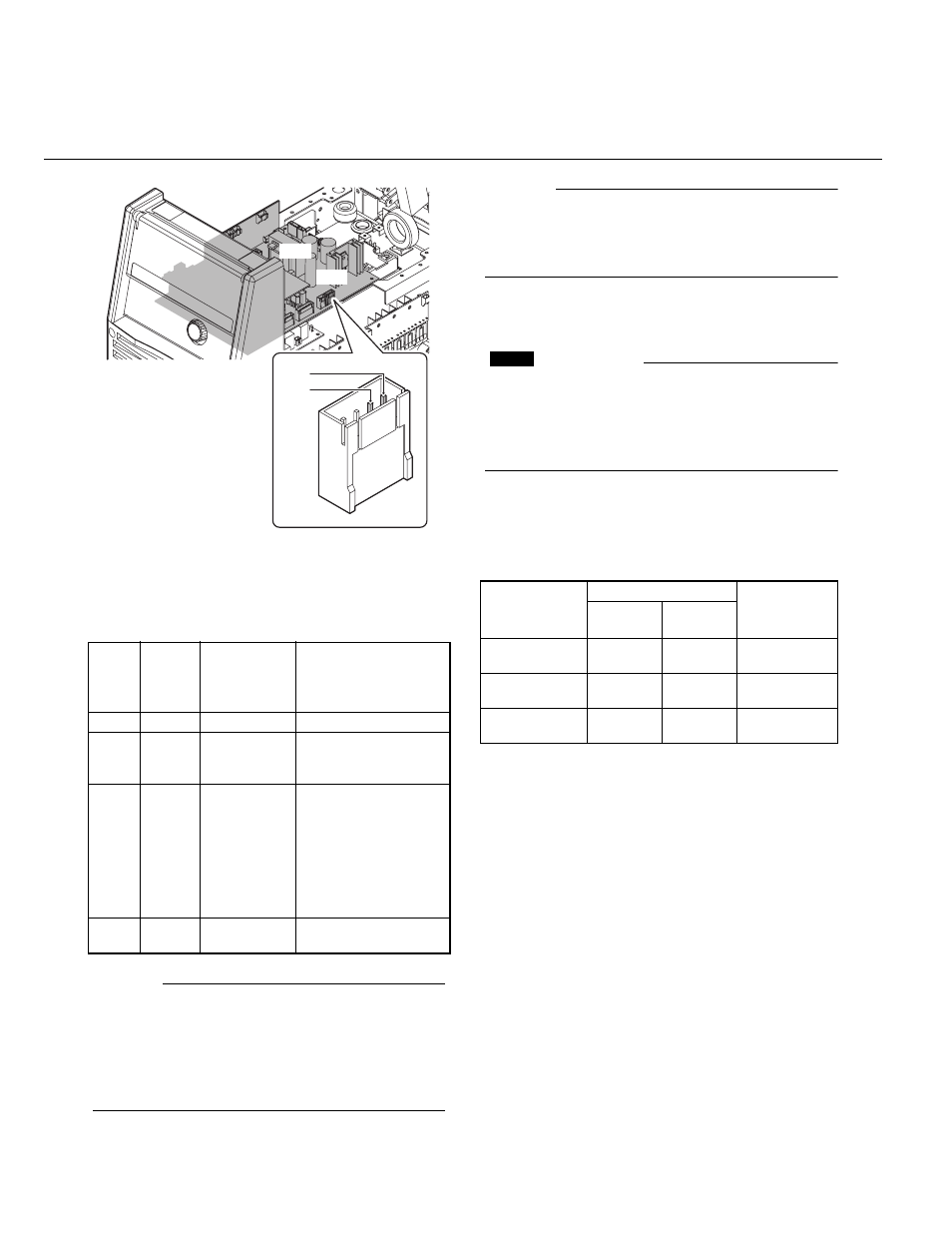

Figure 9-6: The location of connector CN11 of PCB3

(WK-5548)

Using the measurement taken above, follow the

chart below for possible failure modes.

NOTE

This welding unit has a feature that will slow the

rotational speed of the cooling fan during low out-

put current and while in standby. Under these con-

ditions, the voltages in the above table will be

inaccurate; therefore, when verifying the voltage,

do so during the failure condition.

NOTE

When verifying the voltage, confirm that the AC

input voltage remain within the operating range of

the unit. (The AC input does not drop below

180VAC).

1.4.5 Verification of the primary Diode

(D1)

CAUTION

Before performing any portion of the procedure

below, make certain unit is placed in the initial set

up condition as described in section 9.1.4.1

"Preparation".

1. Verify the characteristic of the primary diode,

D1, using a diode tester.

2. Refer to Table 9-1 and Figure 9-7, 9-8 for the

checkpoints on D1.

Table 9-1: Tester checkpoints in the primary diode (D1)

Fan

Status

Voltage

measurement

(PIN1-PIN2 of

CN11 on PCB3)

Remedy

Case1 Rotating DC 18~25V

Fan drive circuit is normal.

Case2 Rotating Below DC 18V

Replace PCB3 (WK-

5548). (Refer to section

9.2.4.3)

Case3 Inactive Below DC 18V

Replace PCB3 (WK-

5548). (Refer to section

9.2.4.3)

↓

Conduct the

"Verification of the

power input circuitry" in

section 9.1.4.2.

Case4 Inactive DC 18~25V

Replace FAN1. (Refer

to section 9.2.4.19)

PCB3

CN11

PIN2

PIN1

COMPONENT

TESTED

TERMINALS

ACCEPTABLE

VALUE

Positive

lead

Negative

lead

Diode of D1

3, 4, 5

0

0

3, 4, 5

0.3 to 0.5V

Open

Diode of D1

3, 4, 5

2

2

3, 4, 5

Open

0.3 to 0.5V

Thyristor of D1

0

1

1

0

Open

Open