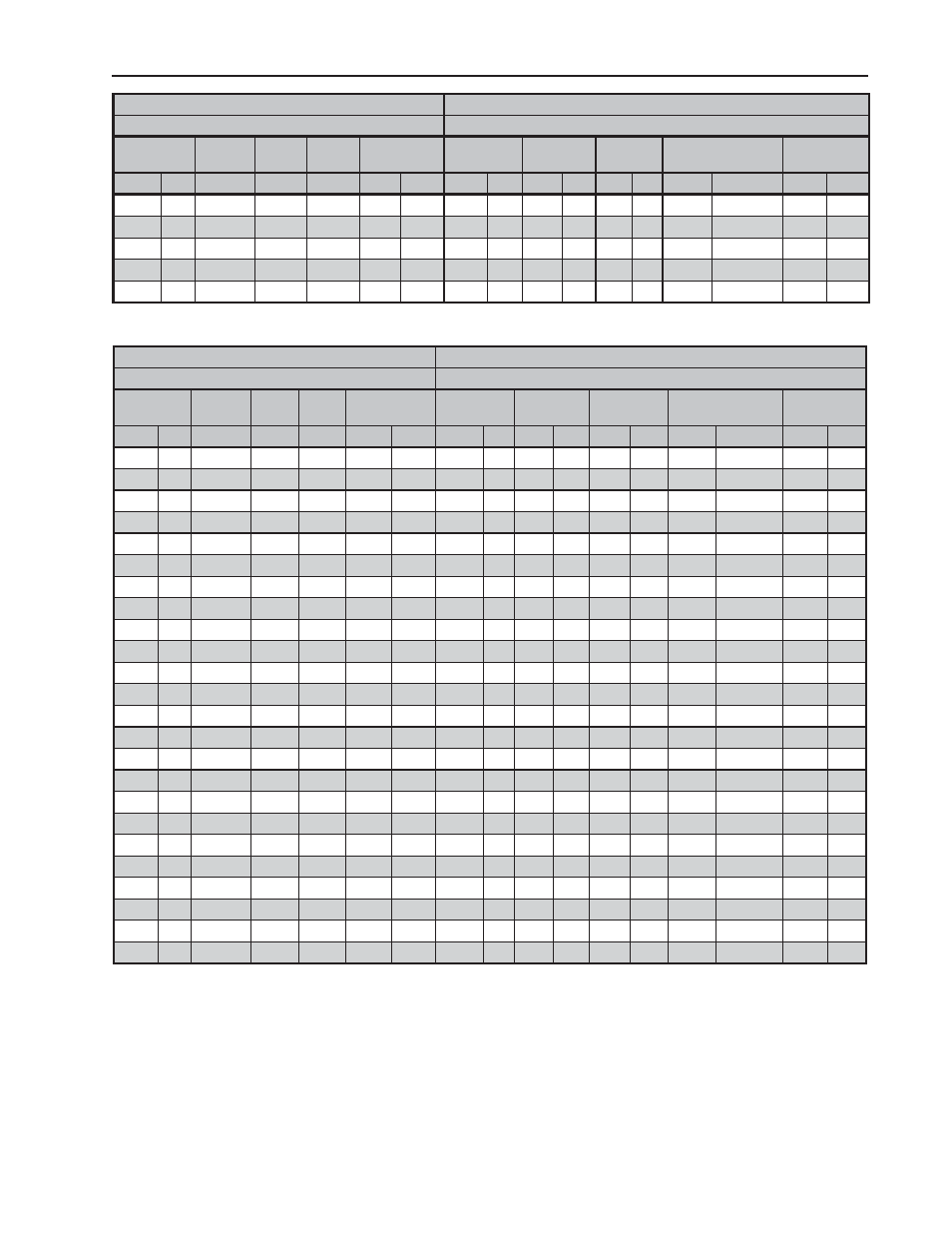

Operation pak 200, Table 4-10: cut chart stainless steel - air/air, Table 4-11: cut chart mild steel - air/air – Tweco Pak 200 User Manual

Page 53

OPERATION

PAK 200

Manual 0-5057 4-9 OPERATION

Type Torch: PCH-200

Type Material: Stainless Steel

Type Plasma Gas: Air

Type Secondary Gas: Air

Thickness

Tip

Output

Volts

Amperage

Speed

(Per Minute)

Standoff

Plasma Gas

Press

Sec Gas

Press

Total Flow (SCFH)

Pierce Height

Inches

mm

(Cat. No.)

(VDC)

(Amps)

Inches Meters Inches

mm

psi

bar

psi

bar

Plasma

Secondary

Inches

mm

0.625

15.9

32-1322 140

120

30

0.8

0.19

4.8

75

5.2

60

4.1

90

340

0.25

6.4

0.750

19.1

32-1322 145

120

25

0.6

0.19

4.8

75

5.2

60

4.1

90

340

N/R N/R

1.250

31.8

32-1322 160

120

10

0.3

0.19

4.8

75

5.2

60

4.1

90

340

N/R N/R

0.500

12.7

32-1323

150

200

110

2.8

0.2

5.1

70

4.8

60

4.1

85

340

0.40

10.2

0.750

19.1

32-1323

165

200

35

0.9

0.2

5.1

70

4.8

60

4.1

85

340

0.50

12.7

Table 4-10: Cut Chart Stainless Steel - Air/Air

Type Torch: PCH-200

Type Material: Mild Steel

Type Plasma Gas: Air

Type Secondary Gas: Air

Thickness

Tip

Output

Volts

Amperage

Speed

(Per Minute)

Standoff

Plasma Gas

Press

Sec Gas Press

Total Flow (SCFH)

Pierce Height

Inches

mm

(Cat. No.)

(VDC)

(Amps)

Inches Meters

Inches

mm

psi

bar

psi

bar

Plasma

Secondary

Inches

mm

21 ga 0.8

32-1320

95

35

400

10.2

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

18 ga 1.2

32-1320

100

35

300

7.6

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

16 ga 1.5

32-1320

100

35

275

7

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

13 ga 2.2

32-1320

105

35

150

3.8

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

11 ga 2.9

32-1320

110

35

90

2.3

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

7 ga

4.8

32-1320

110

35

60

1.5

0.13

3.3

65

4.5

60

4.1

50

340

0.13

3.3

0.125

3.2

32-1321 120

70

180

4.6

0.19

4.8

70

4.8

60

4.1

77

340

0.25

6.4

0.188

4.8

32-1321 120

70

140

3.6

0.19

4.8

70

4.8

60

4.1

77

340

0.25

6.4

0.250

6.4

32-1321 122

70

75

1.9

0.19

4.7

70

4.8

60

4.1

77

340

0.25

6.4

0.375

9.5

32-1321 125

70

55

1.4

0.19

4.8

70

4.8

60

4.1

77

340

0.25

6.4

0.500 12.7

32-1321 132

70

35

9

0.19

4.8

70

4.8

60

4.1

77

340

0.25

6.4

0.250

6.4

32-1322 125

120

125

3.2

0.25

6.4

65

4.5

60

4.1

78

340

0.38

9.7

0.375

9.5

32-1322 130

120

80

2

0.25

6.4

65

4.5

60

4.1

78

340

0.38

9.7

0.500 12.7

32-1322 135

120

55

1.4

0.25

6.4

65

4.5

60

4.1

78

340

0.38

9.7

0.625 15.9

32-1322 140

120

40

1

0.25

6.4

65

4.5

60

4.1

78

340

0.38

9.7

0.750 19.1

32-1322 145

120

30

0.8

0.25

6.4

65

4.5

60

4.1

78

340

0.38

9.7

1.000 25.4

32-1322 160

120

15

0.4

0.25

6.4

65

4.5

60

4.1

78

340

N/R N/R

1.250 31.8

32-1322 165

120

12

0.3

0.25

6.4

65

4.5

60

4.1

78

340

N/R N/R

1.500 38.1

32-1322 180

120

5

0.1

0.25

6.4

62

4.3

60

4.1

78

340

N/R N/R

0.50

12.7

32-1323

144

200

85

2.2

0.15

3.8

70

4.8

60

4.1

83

340

0.30

7.6

0.75 19.05 32-1323

150

200

50

1.3

0.18

4.6

70

4.8

60

4.1

83

340

0.35

8.9

1.00

25.4

32-1323

158

200

30

0.8

0.25

6.4

70

4.8

60

4.1

83

340

0.40

10.2

1.50

38.1

32-1323

168

200

15

0.4

0.25

6.4

70

4.8

60

4.1

83

340

N/R N/R

2.00

50.8

32-1323

188

200

10

0.3

0.25

6.4

70

4.8

60

4.1

83

340

N/R N/R

Table 4-11: Cut Chart Mild Steel - Air/Air