06 operational suggestions, Operation pak 200 – Tweco Pak 200 User Manual

Page 49

OPERATION

PAK 200

Manual 0-5057 4-5 OPERATION

times; the status code is 4-3. After a 4-second delay,

the lamp repeats the sequence until the condition is

corrected.

Some conditions can be active indefi nitely, while others

are momentary. The power supply latches momentary

conditions; some momentary errors can shut down

the system. The lamp may show multiple conditions

in sequence; it is important to recognize all possible

conditions that may be displayed. The Error Code sec-

tion provides explanations of status codes.

4. Place RUN/SET switch to SET mode.

a. Gases fl ow to set pressures.

5. Place RUN/SET switch to RUN mode.

a. Gas fl ow stops.

6. Move torch within transfer distance of work piece.

7. Protect eyes and start torch.

a. Power supply enabled. DC lamp turns ON.

b. Gas pre-fl ows starts.

8. Wait for gas pre-fl ow to complete:

a. Pilot arc is established.

9. Main arc transfers to the workpiece.

a. Pilot arc shuts OFF.

10. Complete cutting operation.

11. Stop the torch.

a. Main arc stops.

12. Gas will fl ow briefl y (‘post-fl ow’).

a. Gas solenoid closes; gas fl ow stops:

13. Set the ON/OFF power switch on the front panel of

the unit to OFF.

a. AC Power lamp turns OFF.

b. Fan and pump turn OFF.

14. Place the main power disconnect to open.

a. Main AC power is removed from the system.

4.06 Operational

Suggestions

1. Wait fi ve minutes before setting the ON/OFF switch

to OFF after operation. This allows the cooling fan

to run to dissipate operating heat from the power

supply.

2. For maximum parts life, do not operate the pilot arc

any longer than necessary.

3. Use care in handling torch leads and protect them

from damage.

WARNING

Frequently review the safety precautions in

"1.02

Important Safety Precautions" on

page 1-1. Disconnect primary power at the

source before assembling or disassembling

power supply, torch parts, or torch and

leads assemblies, or adding coolant. It is not

enough to simply move the ON/OFF switch on

the unit to OFF position when cutting opera-

tions have been completed. Always open the

power supply disconnect switch fi ve minutes

after the last cut is made.

1. Connect system to primary input power.

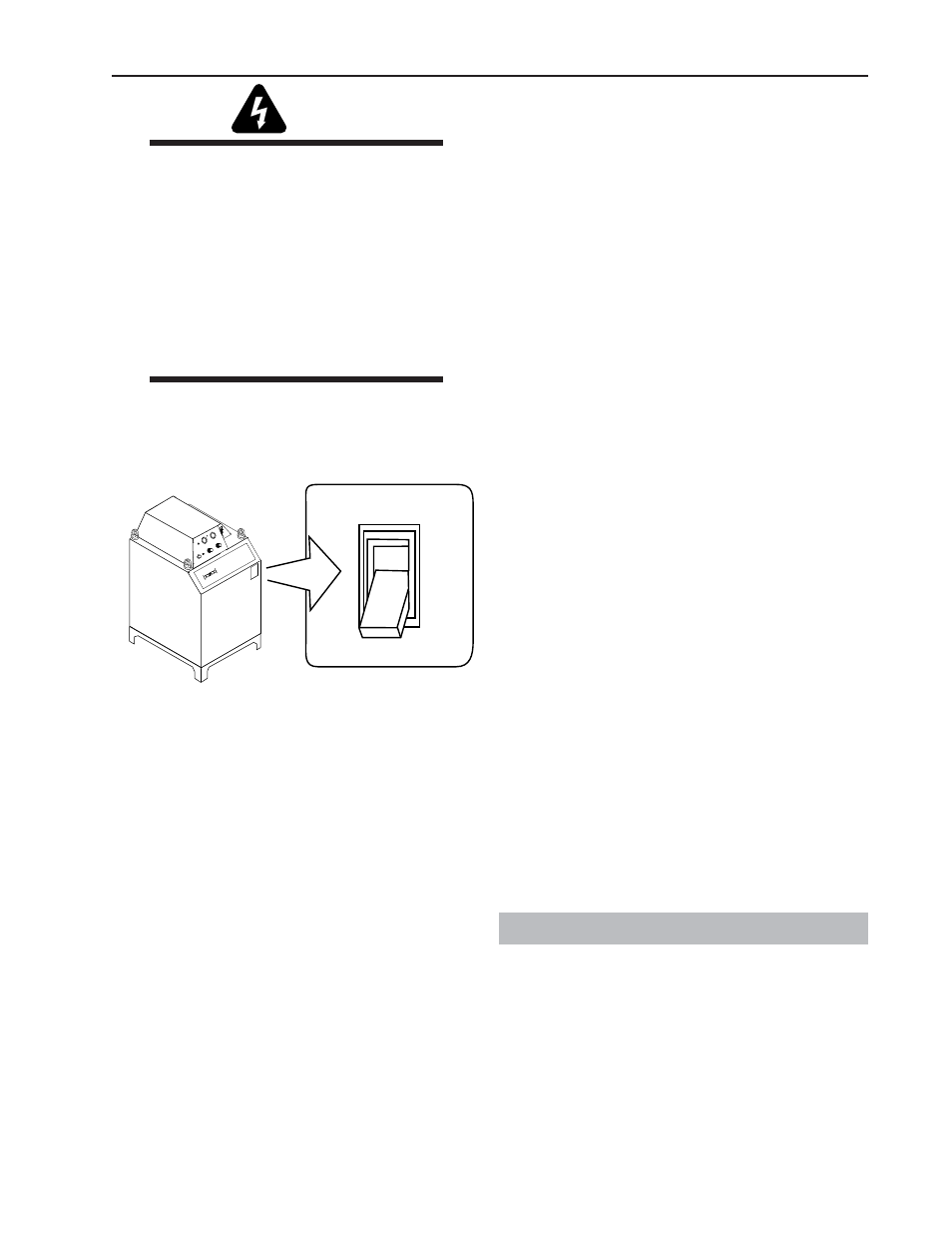

2. Turn ON/OFF switch to ON (up) position. AC Lamp

turns ON. Fan and coolant pump turn on. There is a

start-up purge of gas through the system.

POWER

ON

OFF

O

I

OFF

O

Art # A-04842

Figure 4-7: System Operation

3. Check the AC lamp. If lamp is ON, AC input power is

present in the power supply. Within 4 seconds of the AC

lamp illuminating there will be a series of fl ashes from

the four operation status lamps to show the fi rmware

revision in use. This will be a two part indication. An

example would be two fl ashes followed by a short

pause then four fl ashes then a longer pause. This would

indicate fi rmware revision 2.4. If there is a third group

displayed, it is for Engineering Development only and

not for customer use without written agreement from

Thermadyne. This sequence of AC lamp then fi rmware

revision status will happen at every power up.

Circuitry in the power supply monitors the status of

various conditions. If the circuitry detects a situation

requiring operator attention, the status lamp on the

control panel fl ashes a 2-part code to indicate a code

group and then a particular condition within the group.

After 4 seconds, the sequence repeats.

Example: Lamp fl ashes 4 times; the condition is in

group 4. After a .2 second delay, the lamp blinks 3