What you need to do – Rockwell Automation 20D PowerFlex 700S and 700H Frame 10...12 Rectifier Module Replacement Kit User Manual

Page 4

4

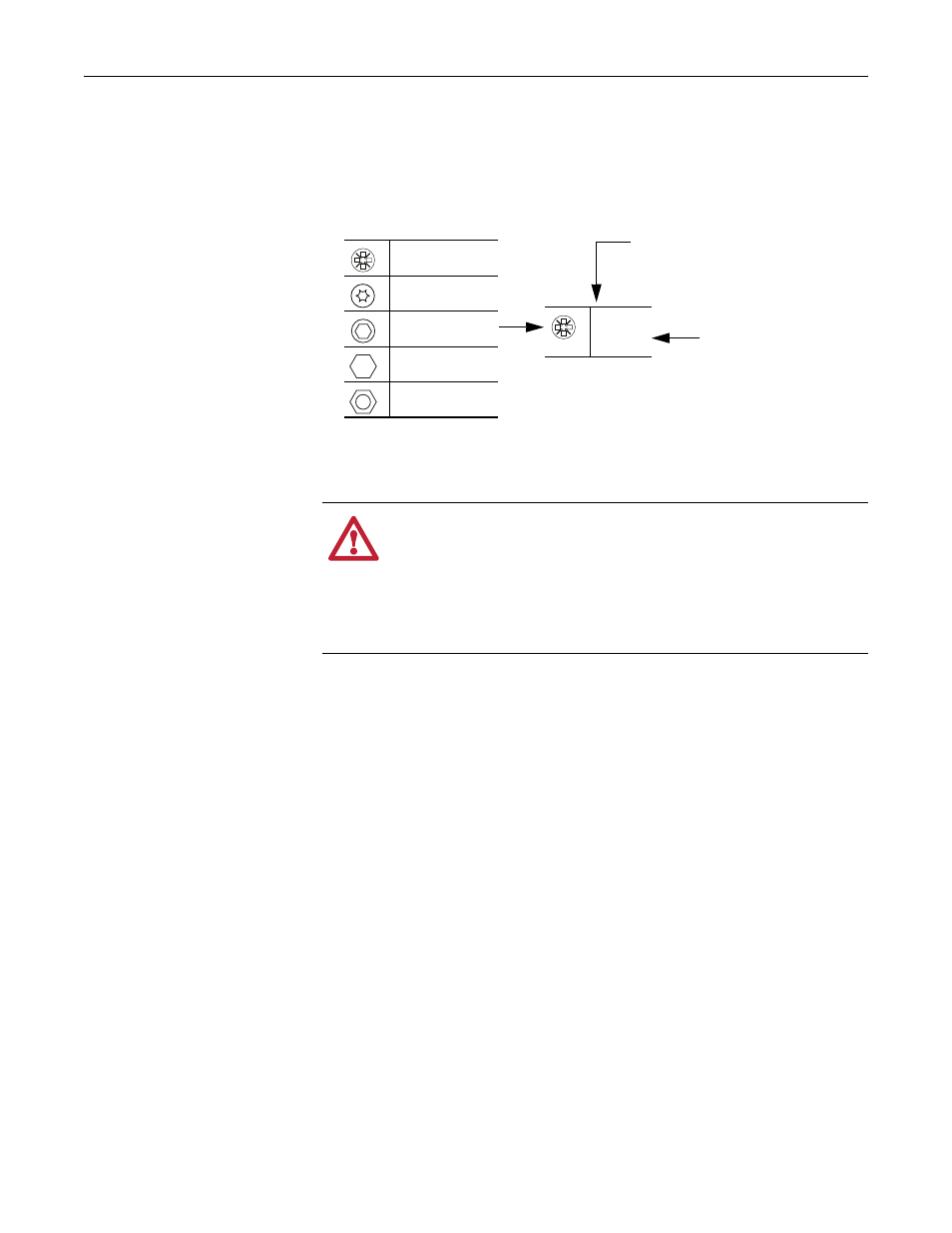

Understanding Torque Figures in Illustrations

Icons and numbers in the assembly illustrations indicate how to tighten

hardware after re-assembly:

What You Need to Do

❐ Step 1:

Remove power from the drive

❐ Step 2:

Remove the protective covers from the drive

❐ Step 3:

Remove the power structure from the enclosure

❐ Step 4:

Remove the existing rectifier module

❐ Step 5:

Install the new rectifier module

❐ Step 6:

Install the power structure in the enclosure

❐ Step 7:

Complete the circuit tests

❐ Step 8:

Install the protective covers

❐ Step 9:

Document the change

ATTENTION: A hazard of personal injury and/or equipment

damage exists if the hardware securing power components in the

drive is not installed in the same location from which it was removed,

according to size, and the specified torque is not applied, where

indicated. Take the appropriate steps to ensure that the location and

size of hardware has been noted during disassembly and that proper

torque is applied as indicated during re-assembly.

PZ2

4 N•m

(35 lb•in)

Tool Type and Size:

PZ = POZIDRIV screwdriver bit

T = Hexalobular (TORX) screwdriver bit

xx mm = Socket wrench

HEX = Hexagonal screwdriver/bit

Tightening Torque

Fastener Type:

POZIDRIV Screw

Hexalobular

(TORX) Screw

Hexagonal Screw

Hexagonal Bolt

Hexagonal Nut