Rockwell Automation GV3000/SE 230VAC 30-100HP GP & Vector Drive V6.04 Start-Up and Reference Manual User Manual

Page 211

F-3

Using the Terminal Strip Analog Input

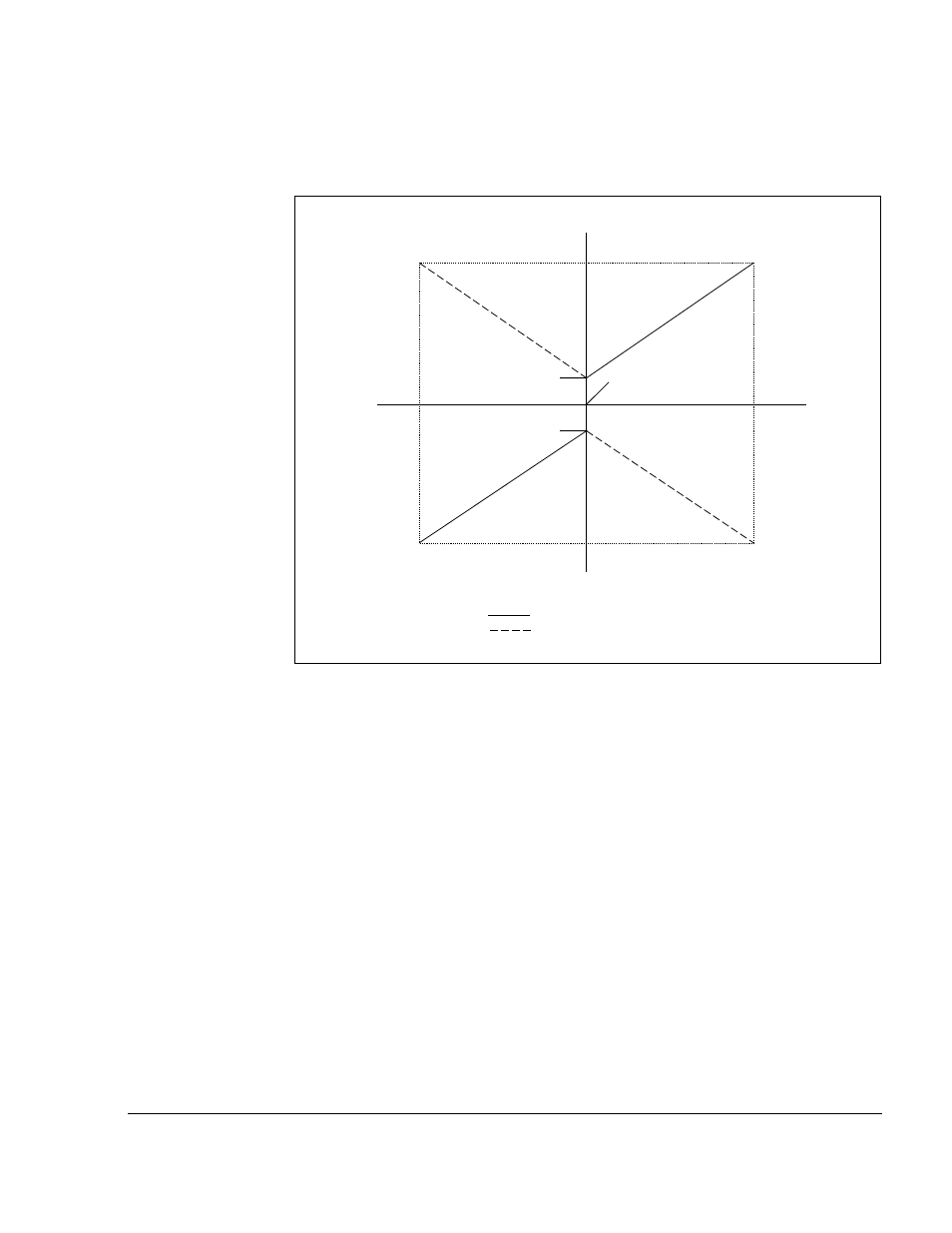

Figure F.2 illustrates how the analog signal is scaled internally by the drive when it

is used as the speed or trim reference. The solid line indicates the conversion when

the non-inverted state is selected (P.011 is even). The dashed line indicates the

conversion when the inverted state is selected (P.011 is odd).

Figure F.2 – Analog Input Conversion Scaling (Speed or Trim Reference)

F.2.1 Adjusting for External Signal Errors Using the Offset and Gain

Parameters

When the analog input is used for speed or trim reference, parameters P.009

(Terminal Strip Analog Input Offset) and P.010 (Terminal Strip Analog Input Gain)

can be used to compensate for any offset or gain errors in the external circuitry.

The value in P.009 is first added to the converted 10-bit value and then the gain is

applied. If an offset or gain adjustment is needed, the offset should be adjusted

first, with the minimum input applied, and the gain adjusted last, with the maximum

input applied.

To remove a positive external offset, enter a negative value into P.009. In most

cases, the offset is left at the default value of zero and is only adjusted to counteract

external circuitry errors.

The adjustment range for P.009 is -900 to +900. For 0 to 10 V (or -10 V to +10 V)

input, a value of +1 equals an offset of approximately 10 mV. For 0 to 20 mA input,

a value of +1 equals an offset of approximately 20

µ

A.

+Max Spd

(P.004)

+Min Spd

(P.003)

-Min Spd

(P.003)

-10 vdc

+10 vdc

+20 ma

-Max Spd

(P.004)

Terminal Strip Analog Input

P.011 is even = not inverted

P.011 is odd = inverted

0 VDC

0 to 4 mA