Rockwell Automation GV3000/SE AC Drive 30-100HP, 230VAC V6.04 Hardware Ref, Install, Troubleshooting User Manual

Page 34

3-6

GV3000/SE 230 VAC 30-100 HP Drive, Hardware Reference Version 6.04

3.2.2.2 Recommended Control and Signal Wire Sizes

The recommended wire size to connect I/O signals to the terminal strip on the

Regulator board are shown in table 3.5. Recommended terminal tightening torque

is 0.5 Newton-meters (4.5 in-lb). Operator controls can be up to 303 meters (1000

feet) from the GV3000/SE drive.

Table 3.5 - Recommended Terminal Strip Wire Sizes

3.2.2.3 Recommended Motor Lead Lengths

The following motor lead lengths are recommended to reduce line disturbances and

noise. See figure 3.3.

•

For applications using one motor, motor lead length should not exceed 76

meters (250 feet). Note that drives using vector regulation can only be

connected to one motor at a time.

•

For applications with multiple motors, total motor lead length should not exceed

76 meters (250 feet).

When total lead length exceeds 76 meters (250 feet), nuisance trips can occur,

caused by capacitive current flow to ground. Note that these capacitively-coupled

currents should be taken into consideration when working in areas where drives are

running. If the motor lead length must exceed these limits, the addition of output

line reactors or other steps must be taken to correct the problem. See tables 3.6

and 3.7. Note that the motor lead lengths shown in table 3.6 are only guidelines.

Your application may be restricted to shorter lead length due to:

•

the type of wire

•

the placement of wire (for example, in conduit or a cable tray)

•

the type of line reactor

•

the type of motor.

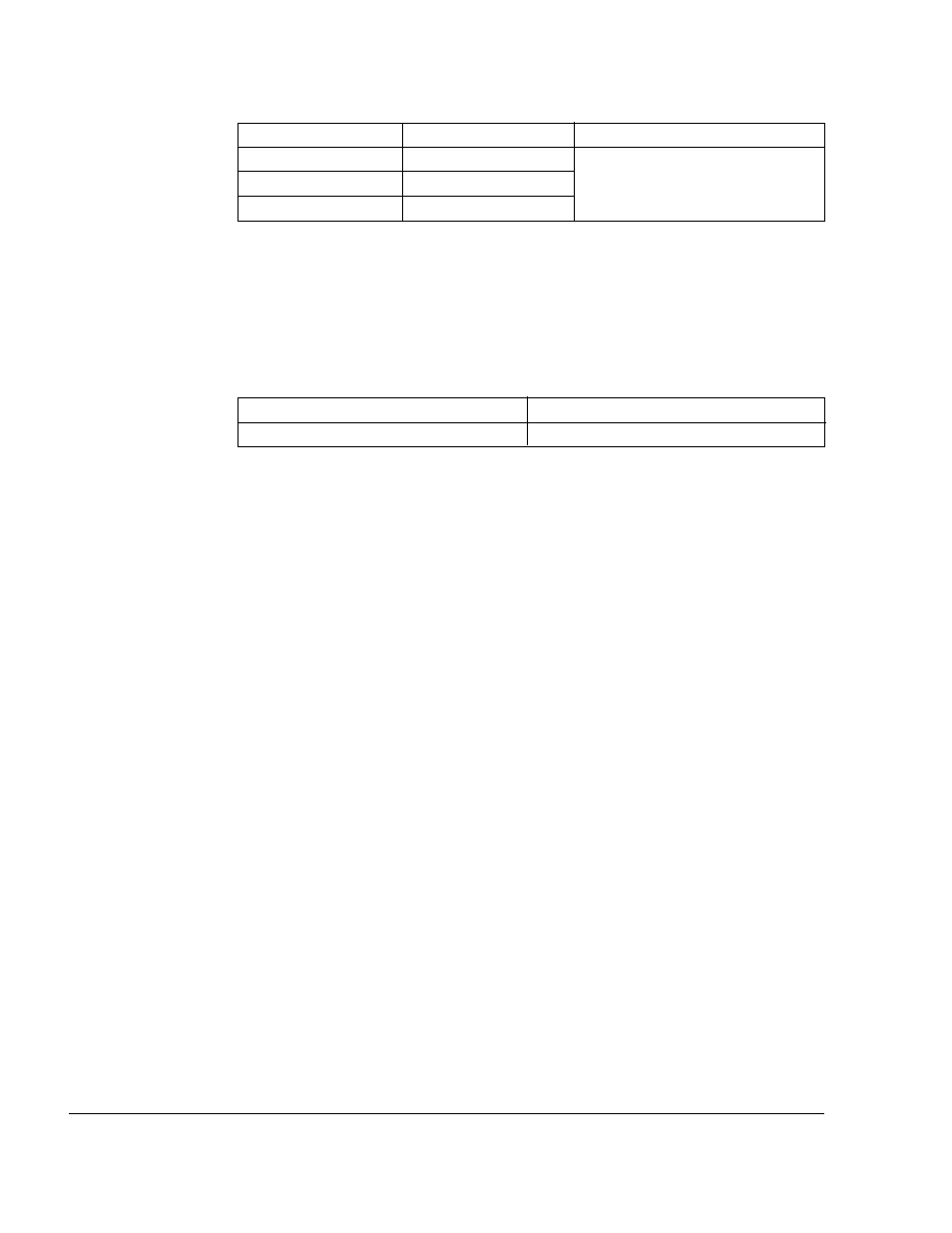

Terminals

1 to 31

Wire Size

20 to 14 AWG, 0.5 to 2 (mm

2

)

Table 3.4 - Recommended Power Wire Sizes for 60 to 100 HP HP Drives

Type of Wiring

AC Input Power

Output Power

DC Input Power

Terminals

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

P, N

Size of Wire (Maximum)

500 Kcmil (or 250 mm

2

)