Setup #1, Setup #2 – Rockwell Automation 1785-Vx0B, D17856.5.9 PLC-5 VME VMEbus Programmable Controllers User Manual User Manual

Page 110

Performance and Theory of Operations

Chapter 7

7-5

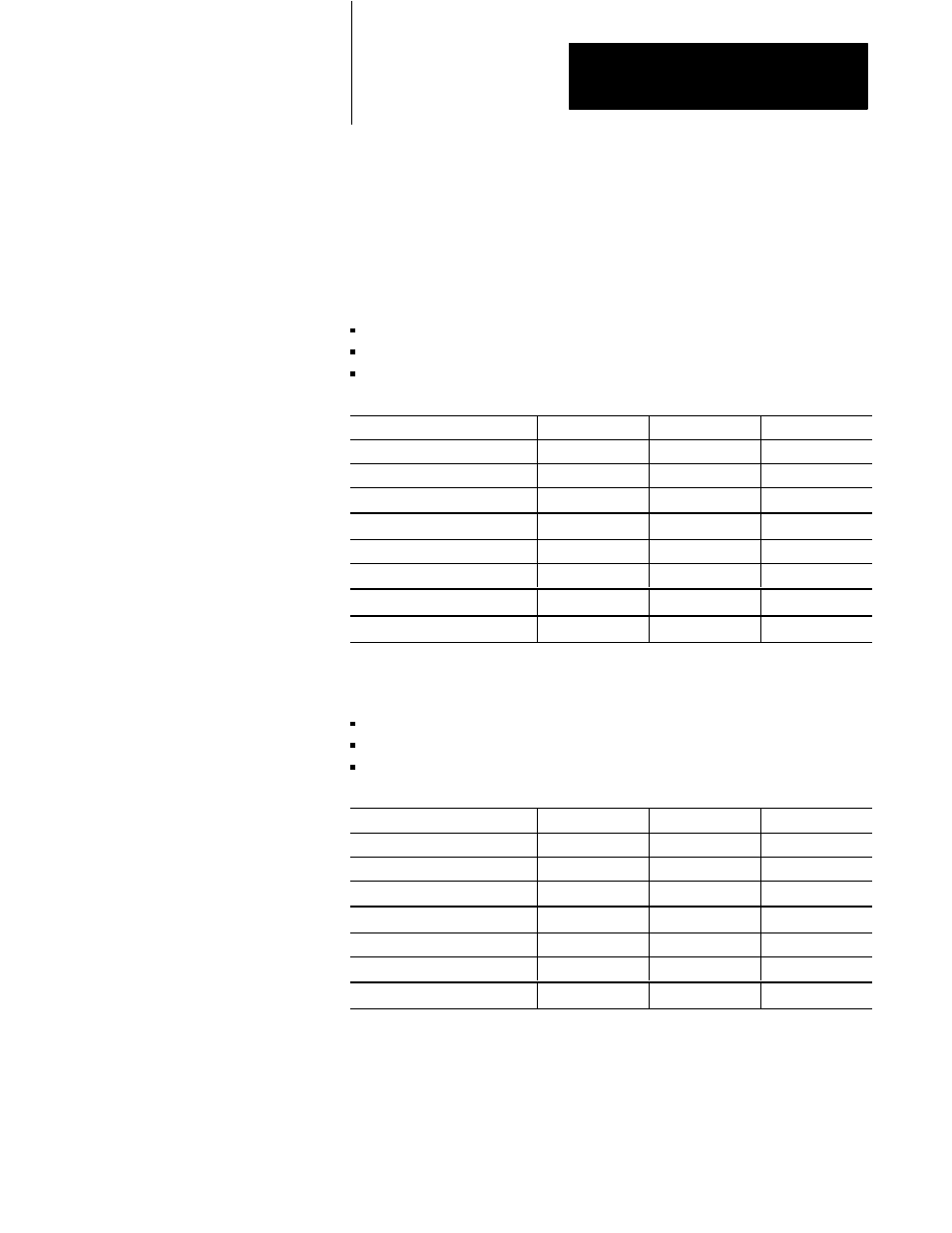

Due to the different loading that can be placed on the communication

processor in the PLC/5 processor, transfer times are not consistent every

time. For each test, 20 readings were taken to calculate the numbers. We

present the minimum, maximum, and average values.

Setup #1

NOCV = 1 (VME coprocessor does not constantly read PLC processor)

Copy to global VME RAM on-board the PLC processor at 0xA00000

Programming terminal not attached to PLC processor

Command

Minimum msec.

Maximum msec.

Average msec.

CTV #N7:0 A0000 D16 1

4.0

8.0

5.0

CTV #N7:0 A0000 D16 500

8.0

9.0

8.0

CTV #N7:0 A0000 D16 1000

12.0

13.0

12.0

CFV A0000 D16 #N7:0 1

4.0

7.0

5.0

CFV A0000 D16 #N7:0 500

8.0

9.0

8.0

CFV A0000 D16 #N7:0 1000

12.0

13.0

12.0

SVE 1 55

3.0

8.0

3.0

CSF

4.0

5.0

4.0

Setup #2

NOCV = 1 (VME coprocessor does not constantly read PLC processor)

Copy to global VME RAM on-board the PLC processor at 0xA00000

Programming terminal attached to PLC processor monitoring ladder file

Command

Minimum msec.

Maximum msec.

Average msec.

CTV #N7:0 A0000 D16 1

4.0

16.0

6.0

CTV #N7:0 A0000 D16 500

8.0

17.0

11.0

CTV #N7:0 A0000 D16 1000

12.0

22.0

14.0

CFV A0000 D16 #N7:0 1

5.0

15.0

7.0

CFV A0000 D16 #N7:0 500

8.0

18.0

12.0

CFV A0000 D16 #N7:0 1000

12.0

17.0

13.0

SVE 1 55

3.0

14.0

5.0