Step 3: lift and mount the drive, Drive weights, Attaching the lifting hardware – Rockwell Automation 20D PowerFlex 700S Phase II Drive Frames 1...6 Installation Instructions User Manual

Page 22

22

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 3: Lift and Mount the

Drive

Drive Weights

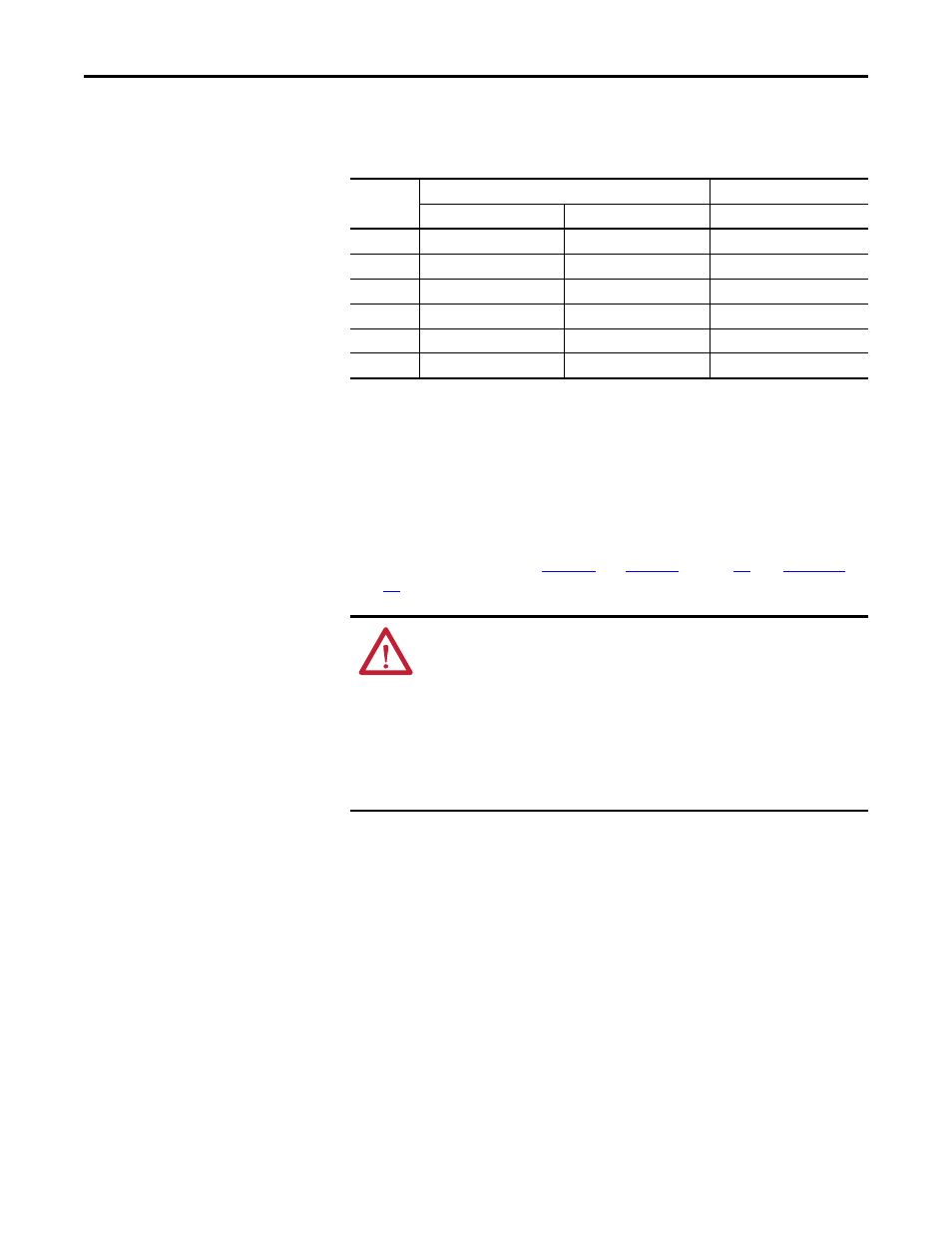

Table 9 - Approximate Drive Weights

Attaching the Lifting Hardware

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

and so forth) must be properly sized and rated to safely lift and hold the weight of

the drive while mounting. See

on page

page

for lifting instructions.

Frame Size

Drive Rating

Drive Weight

(1)

(1) Weights include HIM, DriveLogix controller with ControlNet daughtercard, Hi-Resolution Encoder Option, and 20-COMM-C

ControlNet adapter.

kW

Hp

kg (lb)

1

0.75…11

1…10

7.0 (15.5)

2

7.5…18.5

10…25

12.5 (27.6)

3

11…37

15…50

18.6 (40.9)

4

25…60

18.5…55

24.5 (54.0)

5

40…100

30…90

37.2 (82.0)

6

60…200

45…132

71.5 (157.5)

(2)

(2) Add an additional 3.6 kg (8.0 lb) for 200 Hp drives.

ATTENTION: To guard against possible personal injury and/or equipment

damage…

• Inspect all lifting hardware for proper attachment before lifting drive.

• Do not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• Do not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do not allow personnel or their limbs directly underneath the drive when it is

being lifted and mounted.