Care and use manual – Waters PAH Columns User Manual

Page 3

[ Care and Use ManUal ]

Name of Document

3

3. If a leak occurs between the stainless steel compression screw fitting

and the column endfitting, a new compression screw fitting, tubing and

ferrule must be assembled.

4. An arrow on the column identification label indicates correct direction

of solvent flow.

It is important to realize that extra column peak broadening can destroy suc-

cessful separation. The choice of appropriate column connectors and system

tubing is discussed in detail below.

a. Column Connectors and System Tubing Considerations

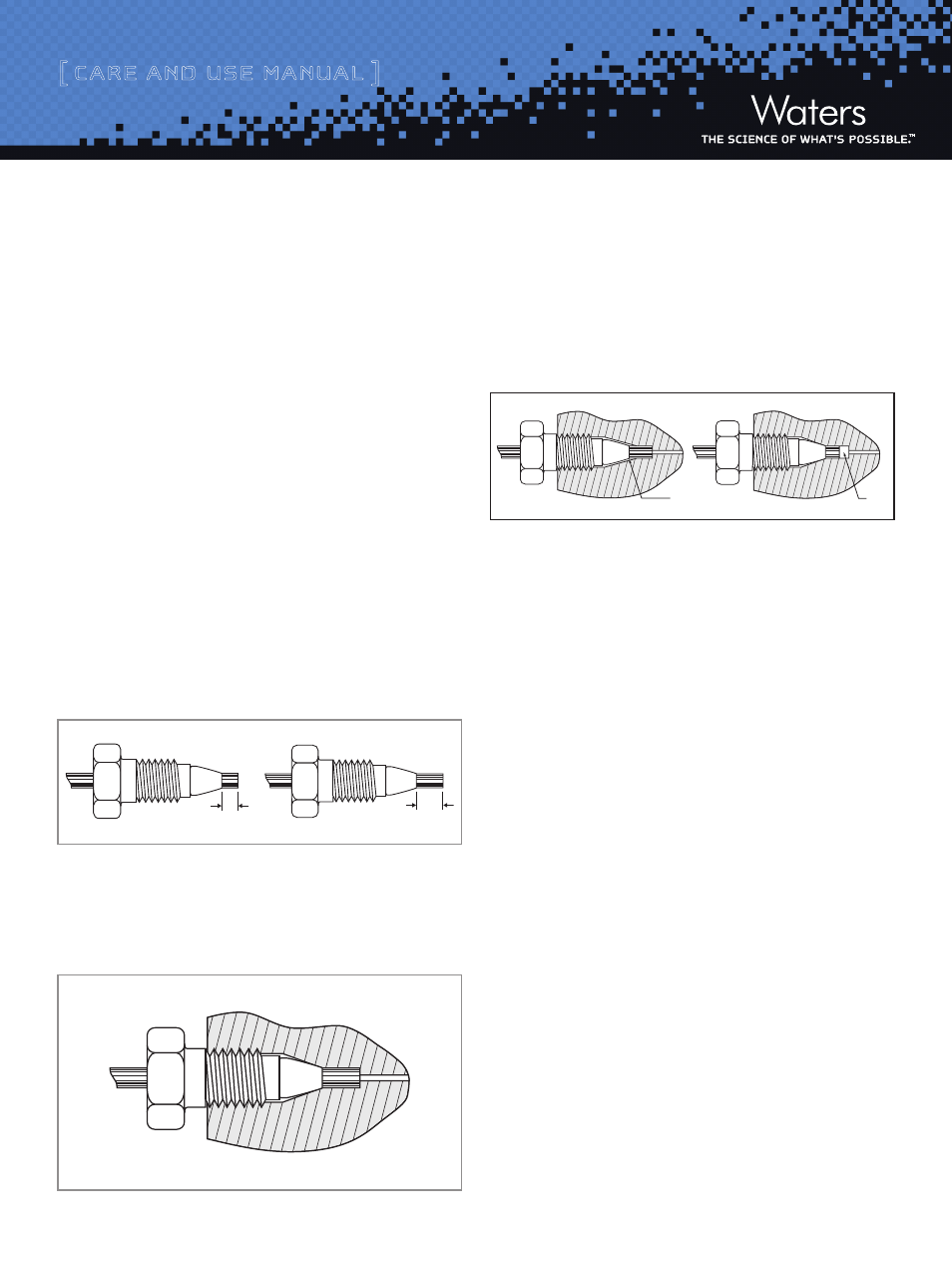

Due to the absence of an industry standard, various column manufacturers

have employed different styles of chromatographic column connectors. The

chromatographic performance of your separation can be negatively affected if

the style of your column endfittings do not match the existing instrumenta-

tion tubing ferrule setting. This page explains the difference between Waters

style and Parker style endfittings, which vary in the required length of the

tubing protruding from the ferrule. The PAH column is equipped with Waters

style endfittings which require a 0.130 inch ferrule depth (see next section

for setting ferrule depth). If you are presently using a non-Waters style

column, it is critical that you reset the ferrule depth for optimal performance.

The Proper Tubing/Column Connection

Tubing touches the bottom of the column endfitting, with no void

between them.

A void appears if a tube with Parker ferrule setting is connected to a Waters

style column.

The presence of a void in the flow stream downgrades the column perfor-

mance. There is only one way to fix the problem: Cut the end of the tubing

with the ferrule, put a new ferrule on the tubing and make the connection.

Before tightening the screw, make sure that the tubing bottoms out in the

endfitting of the column.

If tubing with a Waters style ferrule setting is connected to a column with

Parker style endfitting, the end of the tubing will bottom out before the fer-

rule reaches its proper sealing position. This will leave a gap creating a leak.

There are two ways to fix the problem:

1. Just tighten the screw a little bit more. The ferrule moves forward, and

reaches the sealing surface. Do not overtighten because this may end in

breaking the screw.

2. Cut the tubing, put a new ferrule on it and make the connection.

An alternative is to replace the conventional compression screw fitting with

an all-in-one PEEKTM fitting.

(Waters part number PSL613315) that allows you to reset the ferrule depth.

Another approach is to use a SLIPFREE® fitting to always ensure the correct

fit. The finger-tight SLIPFREE connectors automatically adjust to fit all

compression screw type fittings without the use of tools.

0.090 inches

0.130 inche

Gap

Void