Care and use manual – Waters XBridge Peptide BEH C18 130A and 300A Columns User Manual

Page 7

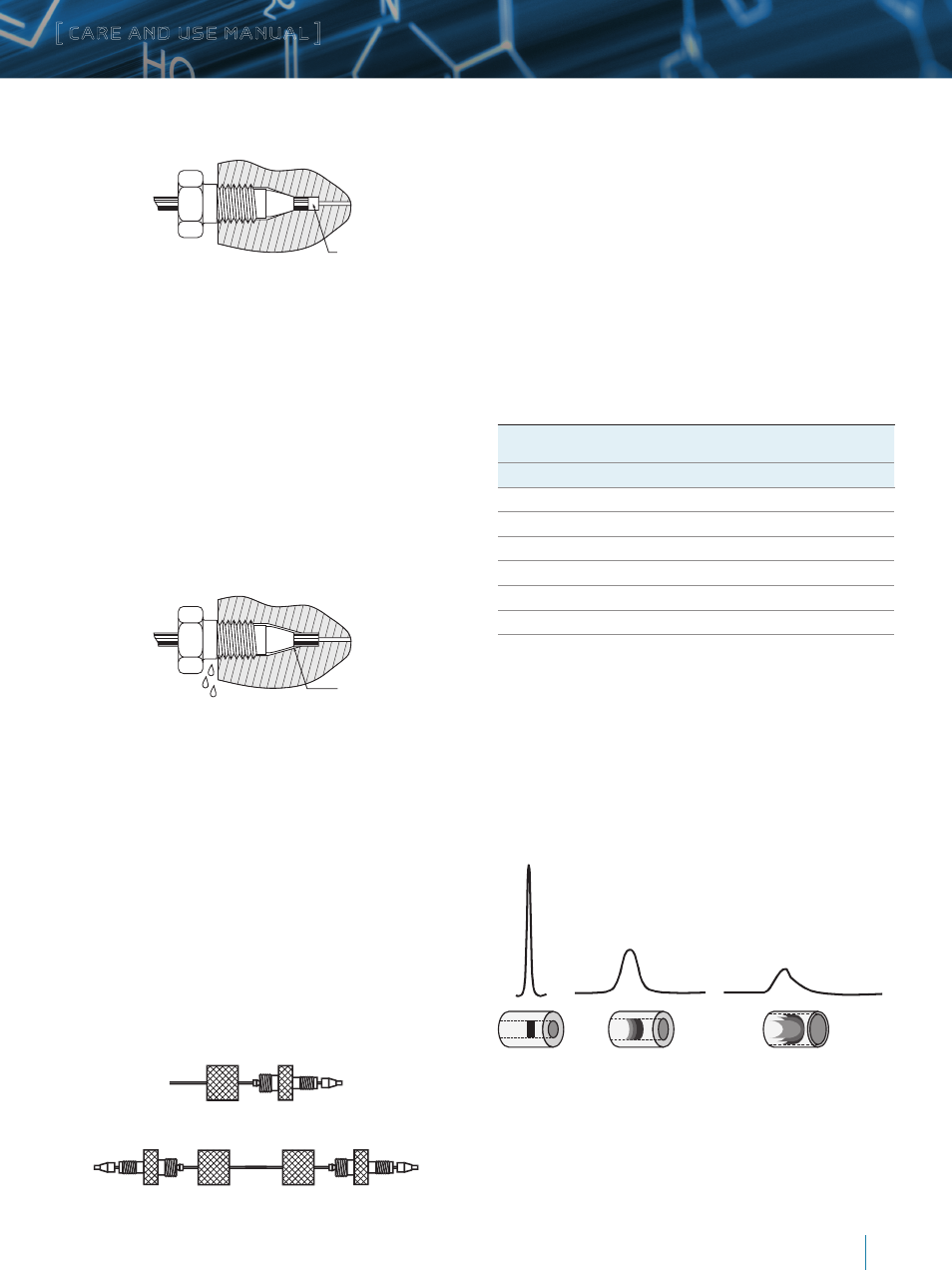

Figure 3. Parker Ferrule in a Waters Style Endfitting.

There is only one way to fix this problem: Cut the end of the tubing

with the ferrule, place a new ferrule on the tubing and make a new

connection. Before tightening the screw, make sure that the tubing

bottoms out in the endfitting of the column.

Conversely, if tubing with a Waters ferrule is connected to a

column with Parker style endfitting, the end of the tubing will

bottom out before the ferrule reaches its proper sealing position.

This will leave a gap and create a leak (Figure 4).

Note: The connection leaks if a Waters ferrule is connected to a

column with a Parker style endfitting.

Figure 4. Waters Ferrule in a Parker Style Endfitting.

There are two ways to fix the problem:

1. Tighten the screw a bit more. The ferrule moves forward, and

reaches the sealing surface. Do not overtighten since this may

end in breaking the screw.

2. Cut the tubing, replace the ferrule and make a new connection.

Alternatively, replace the conventional compression screw fitting

with an all-in-one PEEK™ fitting (Waters Part Number PSL613315)

that allows resetting of the ferrule depth. Another approach is to

use a SLIPFREE

®

connector to always ensure the correct fit. The

fingertight SLIPFREE connectors automatically adjust to fit all

compression screw type fittings without the use of tools (Figure 5).

Figure 5. Single and Double SLIPFREE Connectors.

SLIPFREE connector features:

■

■

Tubing pushed into endfitting, thereby guaranteeing a

void-free connection

■

■

Connector(s) come(s) installed on tubing

■

■

Various tubing i.d’s and lengths available

■

■

Fingertight to 10,000 psi – Never needs wrenches

■

■

Readjusts to all column endfittings

■

■

Compatible with all commercially available endfittings

■

■

Unique design separates tube-holding function from

sealing function

Table 5: Waters Part Numbers for SLIPFREE Connectors

Band Spreading Minimization

Figure 6 shows the influence of tubing internal diameter on

system band spreading and peak shape. As can be seen, the

larger tubing diameter causes excessive peak broadening and

lower sensitivity.

Figure 6. Effect of Connecting Tubing on System.

Gap

Diluted/Distorted Sample Band

0.005 inches

0.020 inches

0.040 inches

SLIPFREE Type

Tubing Internal Diameter

Tubing Length

0.005”

0.010”

0.020”

Single 6 cm

PSL 618000 PSL 618006 PSL 618012

Single 10 cm

PSL 618002 PSL 618008 PSL 618014

Single 20 cm

PSL 618004

PSL 618010

PSL 618016

Double 6 cm

PSL 618001

PSL 618007 PSL 618013

Double 10 cm

PSL 618003 PSL 618009 PSL 618015

Double 20 cm

PSL 618005

PSL 618001 PSL 618017

Void

7

[ CARE AND USE MANUAL ]

XBridge Peptide BEH C

18

, 130Å and 300Å Columns