Care and use manual – Waters XSelect CSH HPLC Columns User Manual

Page 6

[ CARE AND USE MANUAL ]

6

XSelect CSH HPLC Columns

VI. CONNECTING T HE COLUMN TO T HE HPLC

a. Column Connectors and System Tubing Considerations

Tools needed:

• 3/8 inch wrench

• 5/16 inch wrench

Handle the column with care. Do not drop or hit the column on a

hard surface as it may disturb the bed and affect its performance.

1. Correct connection of 1/16 inch outer diameter stainless steel

tubing leading to and from the column is essential for high-quality

chromatographic results.

2. When using standard stainless steel compression screw fittings,

it is important to ensure proper fit of the 1/16 inch outer diameter

stainless steel tubing. When tightening or loosening the compression

screw, place a 5/16 inch wrench on the compression screw and a 3/8

inch wrench on the hex head of the column endfitting.

Note: If one of the wrenches is placed on the column tube flat during this

process, the endfitting will be loosened and leak.

3. If a leak occurs between the stainless steel compression screw fitting

and the column endfitting, a new compression screw fitting, tubing

and ferrule must be assembled.

4. An arrow on the column identification label indicates correct direction

of solvent flow.

Correct connection of 1/16 inch outer diameter stainless steel

tubing leading to and from the column is essential for high-quality

chromatographic results. To obtain a void-free connection, the tubing

must touch the bottom of the column endfitting. It is important to

realize that extra column peak broadening due to voids can destroy

an otherwise successful separation. The choice of appropriate column

connectors and system tubing is discussed in detail below.

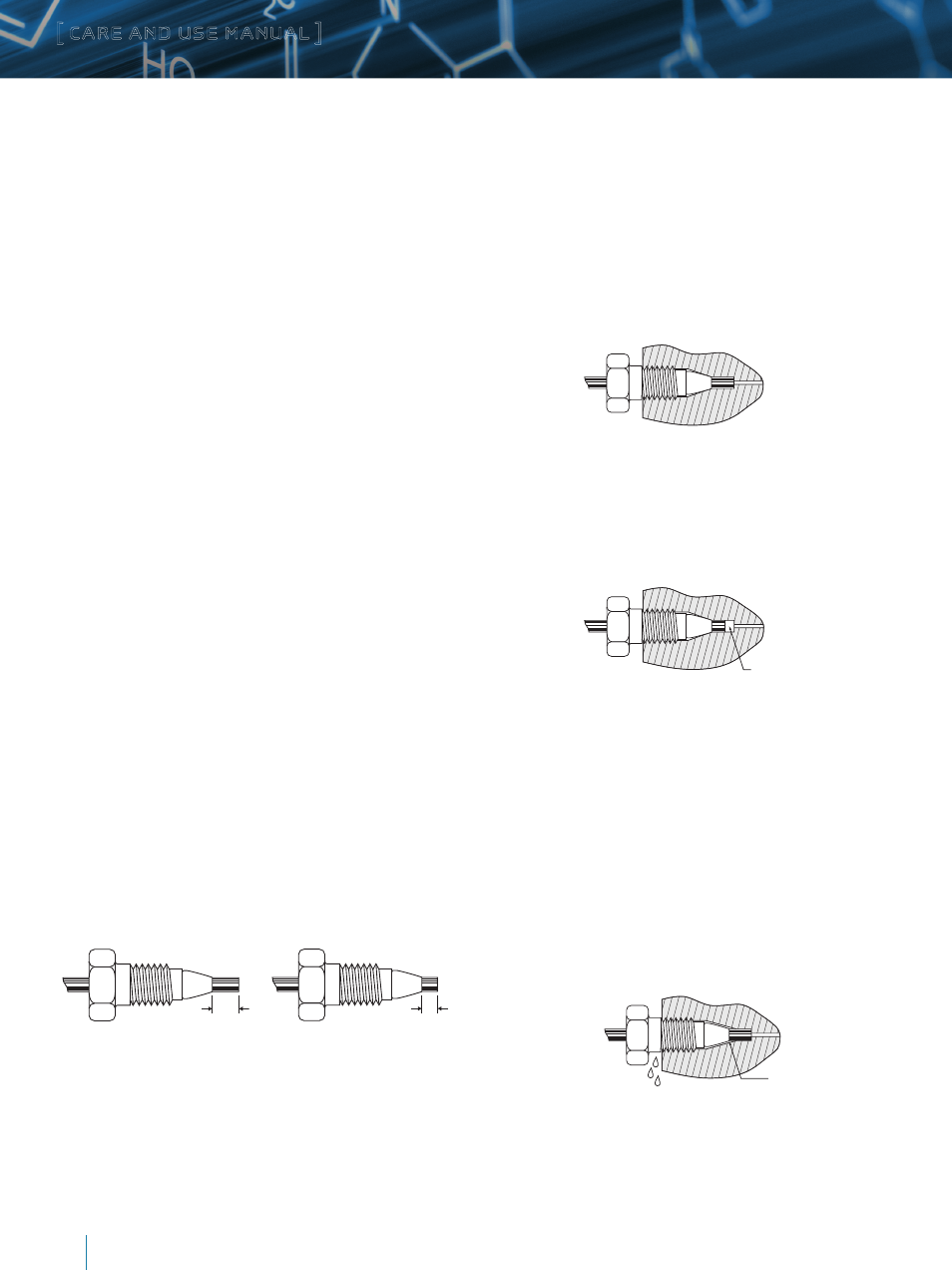

Figure 1: Waters and Parker Ferrule Types

Due to the absence of an industry standard, various column

manufacturers have employed different types of chromatographic

column connectors. The chromatographic separation can be

negatively affected if the style of the column endfittings does not

match the existing tubing ferrule settings. This section explains

the differences between Waters style and Parker style ferrules and

endfittings (Figure 1). Each endfitting style varies in the required

length of the tubing protruding from the ferrule. The XSelect CSH

column is equipped with Waters style endfittings that require a

0.130 inch ferrule depth. If a non-Waters style column is presently

being used, it is critical that ferrule depth be reset for optimal

performance prior to installing an XSelect CSH column.

In a proper tubing/column connection (Figure 2), the tubing touches

the bottom of the column endfitting, with no void between them.

Figure 2: Proper Tubing/Column Connection

The presence of a void in the flow stream reduces column

performance. This can occur if a Parker ferrule is connected to a

Waters style endfitting (Figure 3).

Note: A void appears if tubing with a Parker ferrule is connected to a Waters

style column.

Figure 3: Parker Ferrule in a Waters Style Endfitting

There is only one way to fix this problem: Cut the end of the tubing

with the ferrule, place a new ferrule on the tubing and make a new

connection. Before tightening the screw, make sure that the tubing

bottoms out in the endfitting of the column.

Conversely, if tubing with a Waters ferrule is connected to a

column with Parker style endfitting, the end of the tubing will

bottom out before the ferrule reaches its proper sealing position.

This will leave a gap and create a leak (Figure 4).

Note: The connection leaks if a Water ferrule is connected to a column with a

Parker style endfitting.

Figure 4: Waters Ferrule in a Parker Style Endfitting

Waters Ferrule Setting

Parker Ferrule Setting

0.090 inches

.130”

.090”

Void

Gap