Care and use manual, I. get ting start ed, A. column installation – Waters XSelect CSH HPLC Columns User Manual

Page 2: B. column equilibration, C. initial column efficiency determination

[ CARE AND USE MANUAL ]

2

XSelect CSH HPLC Columns

I. GET TING START ED

Each XSelect CSH column comes with a Certificate of Analysis and

a Performance Test Chromatogram. The Certificate of Analysis is

specific to each batch of packing material contained in the XSelect

CSH column and includes the batch number, analysis of unbonded

particles, analysis of bonded particles, and chromatographic

results and conditions. The Performance Test Chromatogram is

specific to each individual column and contains information such

as: batch number, column serial number, USP plate count, USP

tailing factor, retention factor, and chromatographic conditions.

This data should be stored for future reference.

a. Column Installation

Note: The flow rates given in the procedure below are for a typical 5 µm packing

in a 4.6 mm i.d. column. Scale the flow rate up or down accordingly based upon

the i.d., length, particle size and backpressure of the XSelect CSH column being

installed. See Scaling Up/Down Isocratic Separations section for calculating

flow rates when changing column i.d and/or length. See Connecting the Column

to the HPLC section for a more detailed discussion on HPLC connections.

1. Purge the pumping system of any buffer-containing mobile phases

and connect the inlet end of the column to the injector outlet. An

arrow on the column identification label indicates the correct

direction of solvent flow.

2. Flush column with 100% organic mobile phase (methanol or

acetonitrile) by setting the pump flow rate to 0.1 mL/min and

increase the flow rate to 1 mL/min over 5 minutes.

3. When the mobile phase is flowing freely from the column

outlet, stop the flow and attach the column outlet to the

detector. This prevents entry of air into the detection system

and gives more rapid baseline equilibration.

4. Gradually increase the flow rate as described in step 2.

5. Once a steady backpressure and baseline have been achieved,

proceed to the next section.

Note: If mobile-phase additives are present in low concentrations (e.g., ion-pairing

reagents), 100 to 200 column volumes may be required for complete equilibration. In

addition, mobile phases that contain formate (e.g., ammonium formate, formic acid,

etc.) may also require longer initial column equilibration times.

b. Column Equilibration

XSelect CSH columns are shipped in 100% acetonitrile. It is

important to ensure mobile-phase compatibility before changing

to a different mobile-phase system. Equilibrate the column with

a minimum of 10 column volumes of the mobile phase to be used

(refer to Table 1 for a listing of empty column volumes).

To avoid precipitating out mobile-phase buffers on your column

or in your system, flush the column with five column volumes of

a water/organic solvent mixture, using the same or lower solvent

content as in the desired buffered mobile phase. (For example,

flush the column and HPLC system with 60% methanol in water

prior to introducing 60% methanol/40% buffer mobile phase).

c. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it in the desired

application. Waters recommends using a suitable solute mixture,

as found in the “Performance Test Chromatogram”, to analyze the

column upon receipt.

2. Determine the number of theoretical plates (N) and use this value for

periodic comparisons.

3. Repeat the test at predetermined intervals to track column

performance over time. Slight variations may be obtained on

two different HPLC systems due to the quality of the connections,

operating environment, system electronics, reagent quality, column

condition and operator technique.

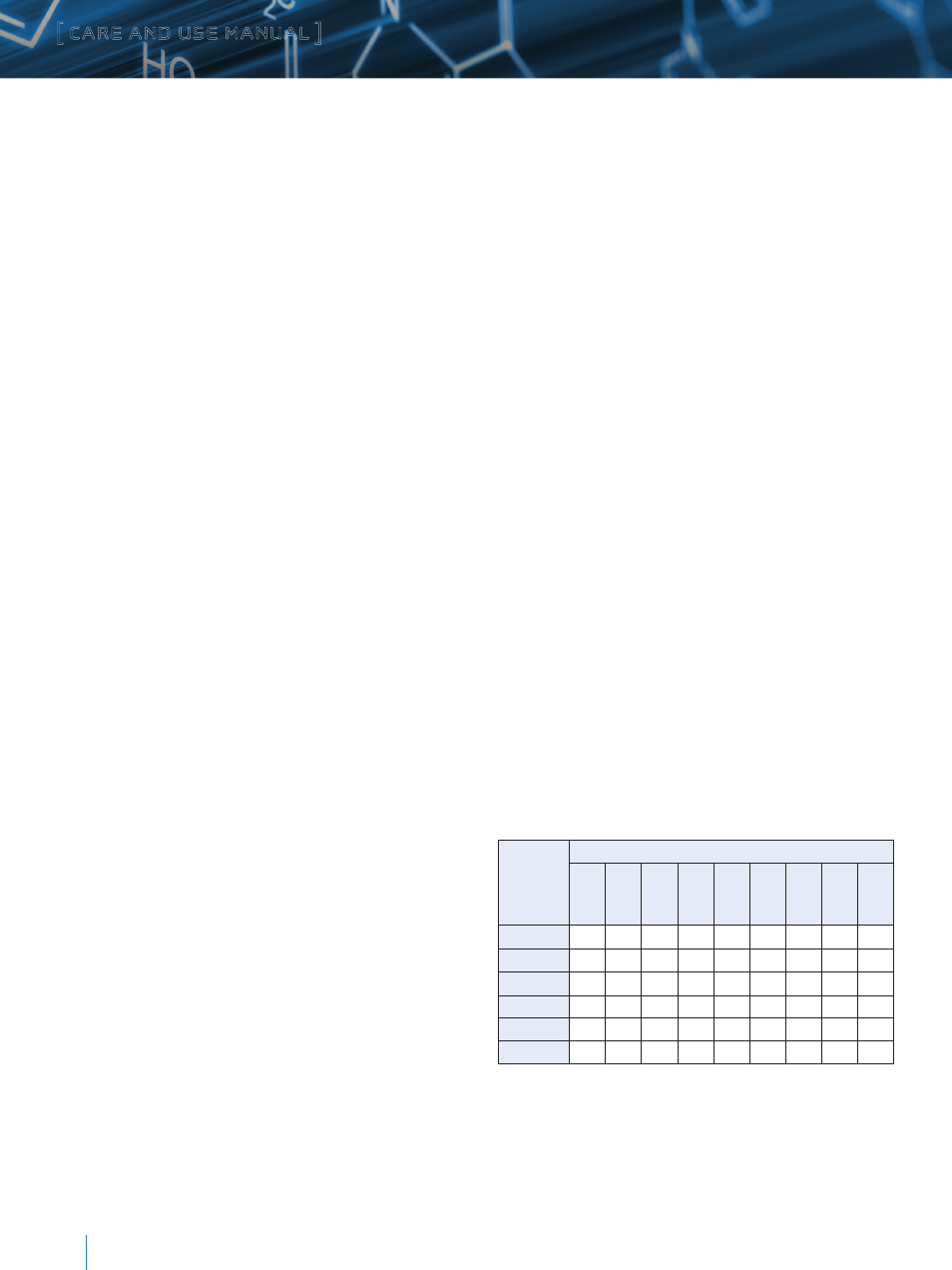

Table 1: Empty Column Volumes in mL (multiply by 10 for flush

solvent volumes)

Column Internal Diameter (mm)

Column

Length

(mm)

1.0

2.1

3.0

4.6

7.8

10

19

30

50

20

-

0.07 0.14 0.33

-

-

-

-

-

30

-

0.10 0.21 0.50

-

2.4

8.5

-

-

50

0.04 0.17 0.35 0.83

2.4

3.9

14

35

98

100

0.08 0.35 0.71

1.7

4.8

7.8

28

70

-

150

0.12 0.52

1.0

2.5

7.2

12

42

106

294

250

-

0.87

1.8

4.2

-

20

70

176

490