Care and use manual, Iv. needle tip installation procedure – Waters Extraction Manifold User Manual

Page 4

4

[ Care and Use ManUal ]

Extraction Manifold

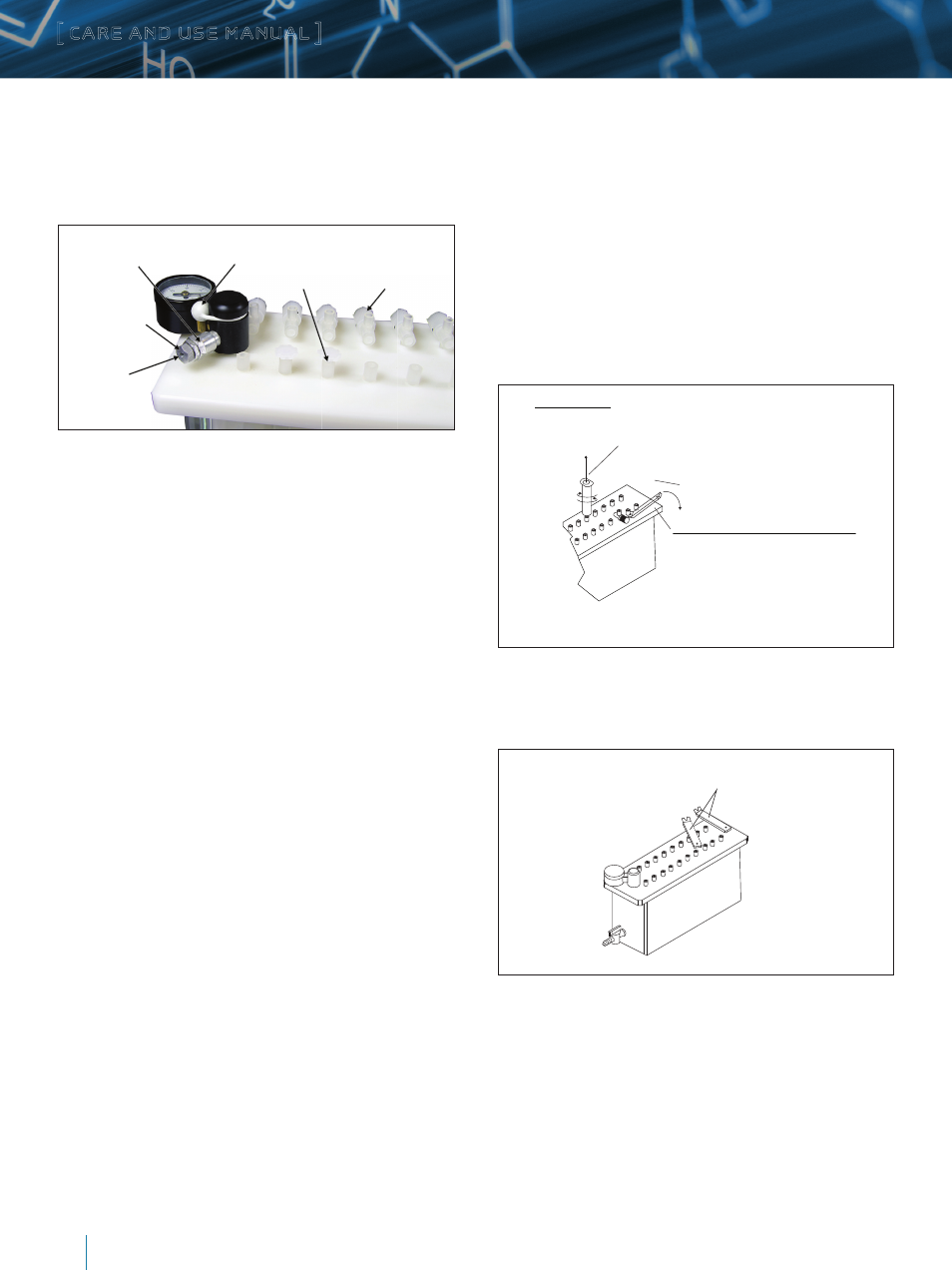

Needle Tip

Luer Plugs:

use to seal open

needle tips

White Rubber Ball:

push it up or down slightly to

release vacuum in chamber

Locking Nut:

(in center) tighten it to

secure set position of

vacuum control valve

Vacuum Control Valve:

rotate outer end to adjust

vacuum to desired level

Bleed Port Hole:

cover it with your

finger tip to increase

vacuum temporarily

To remove a cartridge from the manifold, turn it while pulling it

up. The valve or needle tip) will remain in its socket. To remove

a valve or needle tip from the cover, pry it out carefully with the

ejector tool.

5. For installed needle tips that are not in use, install the Luer

plug by pushing it down in the needle tip(s) input hold (see

Figure 7). Luer plus is used only on the needle tip. Do not

install Luer plug directly on the cover.

6. To remove any of the Luer plugs or columns, first twist the

part then pull upward (see Figures 7 and 8). Pulling is straight

upward is not recommended and can cause the needle tip to

disengage from the cover.

7. To remove needle tips and/or stopcock valves (if used), use the

ejector (see Figure 8).

Figure 4. Close-up View of Vacuum Control and Release Valve Assembly.

Figure 5. Lightly wiggle the needle tip while pushing it down in the hold. Press

it with your thumb and then using the ejector handle push it hard against the

hole to ensure a good contact (also see Figure 5 and Step 3 on the needle tip

installation procedure).

Figure 6. Place ejector (handle position) horizontally or diagonally across two

needles and press down to ensure proper vacuum seal.

IV. needle tIP InstallatIon Procedure

Attention: To achieve proper sealing between the needle tips and the

holds on the cover, this procedure requires that the cover must be placed

on the glass chamber! Not following this requirement will result in

improper needle seating that can lead to low or lost vacuum pressure and/

or damage to the three alignment posts on the underside of the cover.

Make sure that the cover is resting on the class chamber’s edges and not

on the rack.

1. Remove the rack from inside the glass chamber. Alternatively,

with the rack inside the chamber, ensure that the cover’s 3

posts are in the correct alignment with the rack and are not

touching/resting on the rack.

2. Align and place the cover on the glass chamber, make sure it is

seating properly around the edges of the class chamber.

3. Insert a needle tip in the hold and lightly wiggle the needle

while pushing it down inside the hexagon hole until it feels that

the serrated portion of the needle body is seated against the

corners of the hexagon shaped hold on the cover (see Figure

5). Then with your thumb, push the needle as far as it can go.

Repeat the same steps, for the rest of the needle tips. The same

method is also used to install stopcock valves (if used).

4. Place the ejector handle portion, horizontally or diagonally,

on top of two needles and press it down hard. Repeat the same

steps on all the needles (see Figure 6). It is also applied toward

the installation of the stopcock valves (if used).

To Remove Columns

Empty Tube! Twist tube to break off contact, then pull upward.

Pulling directly upward without twisting is not recommended and can

casue needle tip to disengage from the cover.

Slide

Twist

and

Pull Up

Push Down Gently

To Remove any of the Needles/Stopcock Valves:

Slide ejector under the needle tip or stopcock

valve and push ejector down.

Caution: Push down gently, pushing ejector down too fast or

too hard will cause the part to bounce off in the air

Place ejector (handle portion) horizontally or diagonally across

two needles and press down to assure proper vacuum seal