Care and use manual – Waters Dye QCRM Kit User Manual

Page 3

Dye Quality Control Reference Material Kit

3

[ CARE AND USE MANUAL ]

Note: When using a different size and type of column than the one

described here, the flow and injection volumes must be adjusted

accordingly. Pressure balancing and flow to the mass spectrometer

need to be performed at the purification flow rate. When using the

column isocratically, the retention time is approximately 90 to

120 seconds, based on the column size and flow rate.

Required materials:

• Stopwatch

• Mobile phases:

– A Water/TFA, 0.1% (v:v)

– B Acetonitrile/TFA, 0.1% (v:v)

• Sample dye kit, part number 716000765

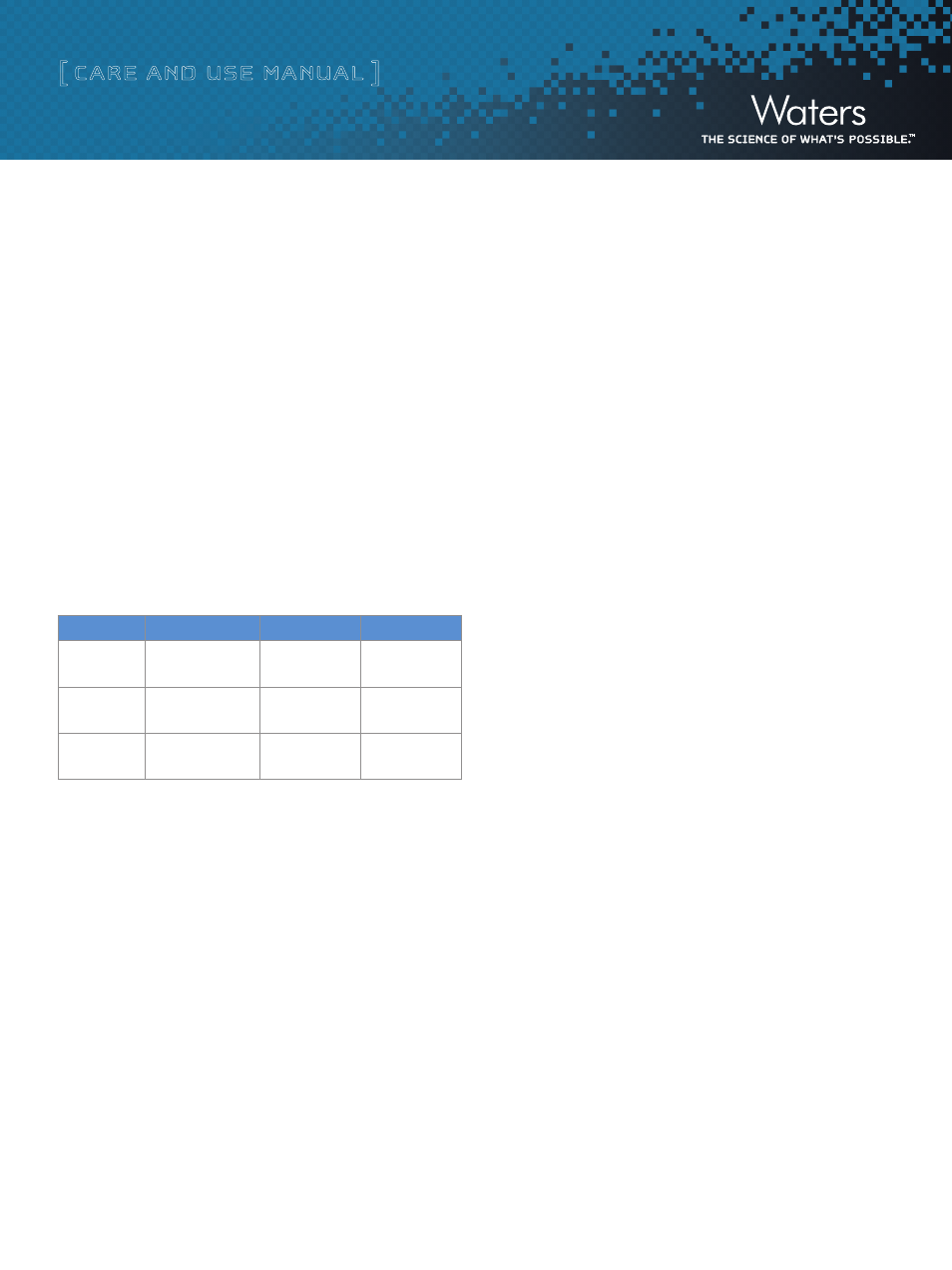

Table 1. Test Dye Compounds Information

Item

Thionin Acetate

Thioflavin T

Crystal Violet

m/z

227.1

282.1

371.2

UV

max

590 nm

418 nm

590 nm

Formula

C

12

H

9

N

3

SC

2

H

4

O

2

C

17

H

19

CIN

2

S

C

25

H

3

0CIN

3

To set up the delay timing test:

1. In the FractionLynx method, set the split collector delay to

30 seconds.

2. In MassLynx

™

, create an inlet method with the following settings:

• Run at the required flow rate for 3 minutes with 10% A

and 90% B.

For UV-directed systems, set the UV detector to the following

parameters, and ensure that the connections on the UV Fraction

Manager correspond to the flow rate used for this test:

– Waters 2998 PDA Detector to scan from 200 to 600 nm

– Waters 2489 UV Detector to monitor 418 nm and 590 nm.

3. For MS-directed systems, create an MS method for a 3 minute scan

acquisition with electrospray + ve, and specify these parameters:

– Centroid = 150 to 550 amu scan for 0.5 seconds

– Inter-scan delay = 0.1 seconds

– Cone Voltage = 35 V.

To run the delay timing test

1. In the MassLynx sample list, specify these values:

• Specify the Injection Volume as 100 μL.

• Enter these values depending upon the detectors configured

in the system:

– For an MS-directed system, enter 227.1 in the Mass A column,

282.1 in the Mass B column, and 371.2 in the Mass C

column. In the Fraction Trigger 1 column, enter Mass A. In

the Fraction Trigger 2 column, enter Mass B. In the Fraction

Trigger 3 column, enter Mass C.

– For a UV-directed system, enter 418 in the Wavelength

A column and 590 in the Wavelength B Column. In the

Fraction Trigger 1 column, enter Wavelength A for a PDA

detector or UV1 for a UV detector, such as a Waters 2489.

In the Fraction Trigger 2 column, enter Wavelength B for a

PDA detector or UV2 for a UV detector.

Tip: UV1 and UV2 correspond to Channel A and Channel B wave-

lengths in the Inlet method. The setting in the Wavelength column is

for reporting purposes only; it does not control the 2489 detector. The

software uses the value set in the Fraction Trigger column, UV 1, UV 2,

against the value set in the Inlet Editor.

2. When the injection occurs, monitor the waste line from the

fraction collector valve. As soon as the dye appears in the

waste line of the fraction collector valve, start the stopwatch.

When you hear the fraction collector valve click to the dispense

position, stop the stopwatch. The dye should have eluted before

the collection valve opened.

4. Calculate the actual Splitter/Collector delay as follows:

The actual delay is equal to original Splitter/Collector delay

specified in the FractionLynx method (e.g., 30 seconds) minus

the time recorded on the stopwatch.