Waters CORTECS 2.7 um Columns User Manual

Page 2

2

CORTECS 2.7 µm Columns

II. GET TING START ED

Each CORTECS 2.7 µm Column comes with a Certificate of

Analysis, which includes the bonded phase batch number and

the analytical test results for the unbonded and bonded particle.

The included Performance Test Chromatogram summarizes

the performance of each individual column and provides batch

number, column serial number, USP plate count, USP tailing

factor, retention factor, and chromatographic test conditions.

These data should be recorded and stored for future reference.

When available, the information can be accessed via the ACQUITY

UPLC Console using the attached eCord.

a. Column Connection

CORTECS 2.7 µm Columns are designed to operate on any HPLC,

UHPLC, or UPLC system. Due to the absence of an industry

standard, be aware that the type of fittings and connection on

each system will vary by manufacturer. All tubing connections

must be reseated to match the new column when it is installed.

If the style of the column endfitting does not properly match the

system connections, the chromatographic performance of your

new column will be negatively impacted, or leaking can occur.

b. Column Installation

Note. The flow rates given in the procedure below are described for

a 2.1 mm i.d. column. Adjust the flow rate up or down based on the

column pressure and system limits.

1. Purge the pumping system of any buffer-containing mobile

phases using 100 % HPLC-grade water.

2. Purge the pumping system to 100% organic mobile phase

(methanol or acetonitrile).

3. Connect the inlet of the column to the chromatographic system.

4. Flush the column with 100% organic mobile phase (methanol

or acetonitrile) by setting the pump flow rate to 0.1 mL/min.

Increase the pump flow rate to 0.5 mL/min over 5 minutes.

5. Once the mobile phase is flowing from the column outlet, stop

the flow.

6. Attach the column outlet to the detector. This prevents air

entering the detector flow cell.

7. Increase the flow rate as described in step 4.

8. Monitor until a steady backpressure and baseline have

been achieved.

c. Minimizing Band Spread Volume

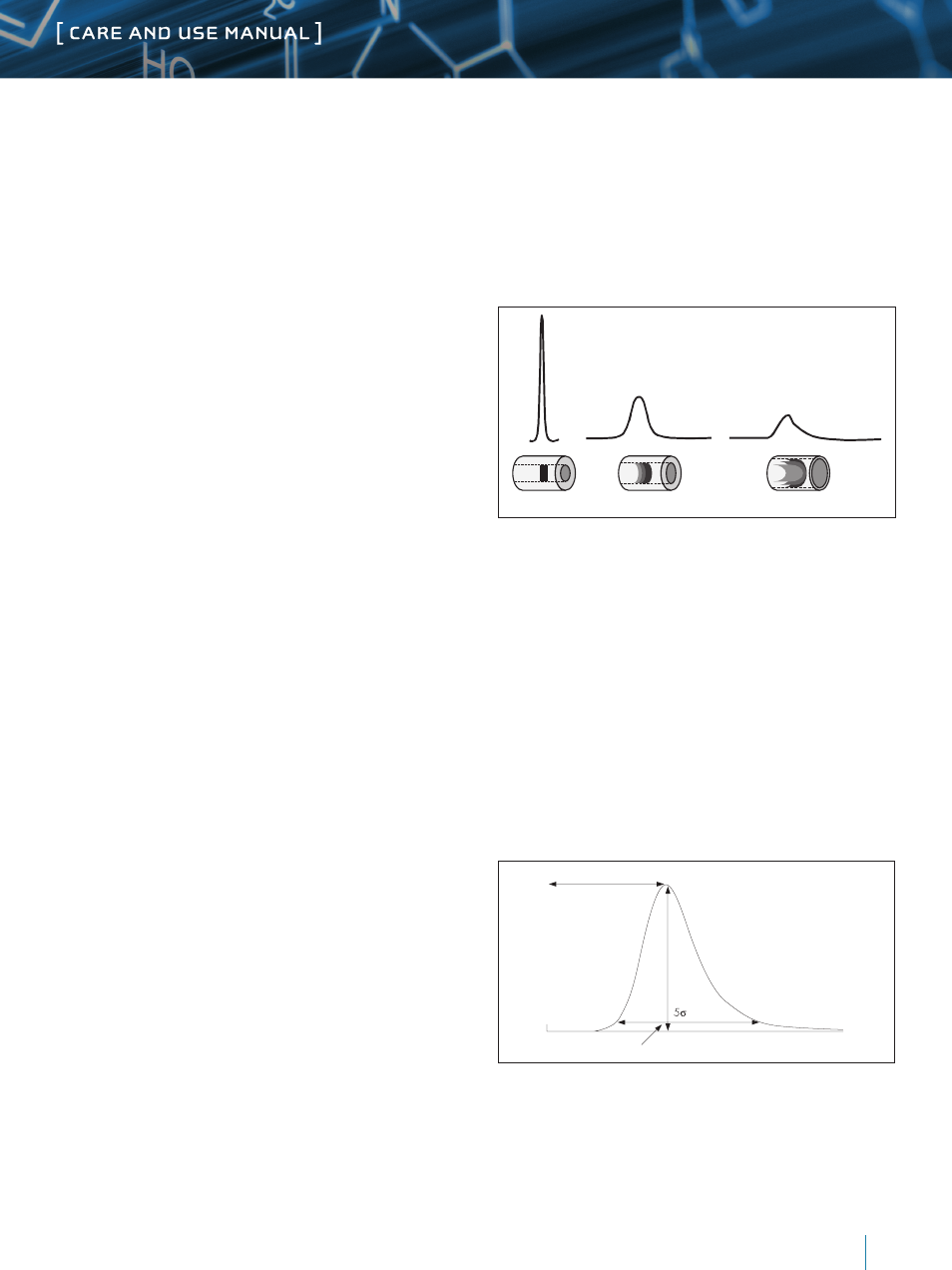

Band spreading is the measurement of the system dispersion,

which impacts the chromatographic performance. Internal tubing

diameter and fluidic connections can significantly impact system

band spreading and chromatographic performance. Larger

tubing diameters cause excessive peak broadening and reduced

sensitivity (Figure 1).

Diluted/Distorted Sample Band

0.005 inches

0.020 inches

0.040 inches

Figure 1. Impact of Tubing Diameter on Band Spread.

d. Measuring Band Spread Volume

This test should be performed on a liquid chromatographic system

equipped with a UV detector.

1. Disconnect the column from the system and replace with a zero

dead volume union.

2. Set the flow rate on the pumping system to 1 mL/min.

3. Use a test mixture (dissolved in the mobile phase conditions)

that delivers a maximum peak height of less than 0.5 AU.

4. Inject 2–5 µL of this solution.

5. Using the 5-Sigma method, measure the peak width in minutes

at 4.4% of peak height:

System Volume

4.4% h

Figure 2. Determination of System Band Spread Volume using 5-Sigma method.

Band Spreading (µL) = Peak Width (min) x Flow Rate (µL/min)

(For example, If peak width = 0.1 min and flow rate = 1000 µL/min,

band spread = 100 µL)