Care and use manual – Waters Sep-Pak XPoSure Aldehyde Sampler User Manual

Page 7

[ CARE AND USE MANUAL ]

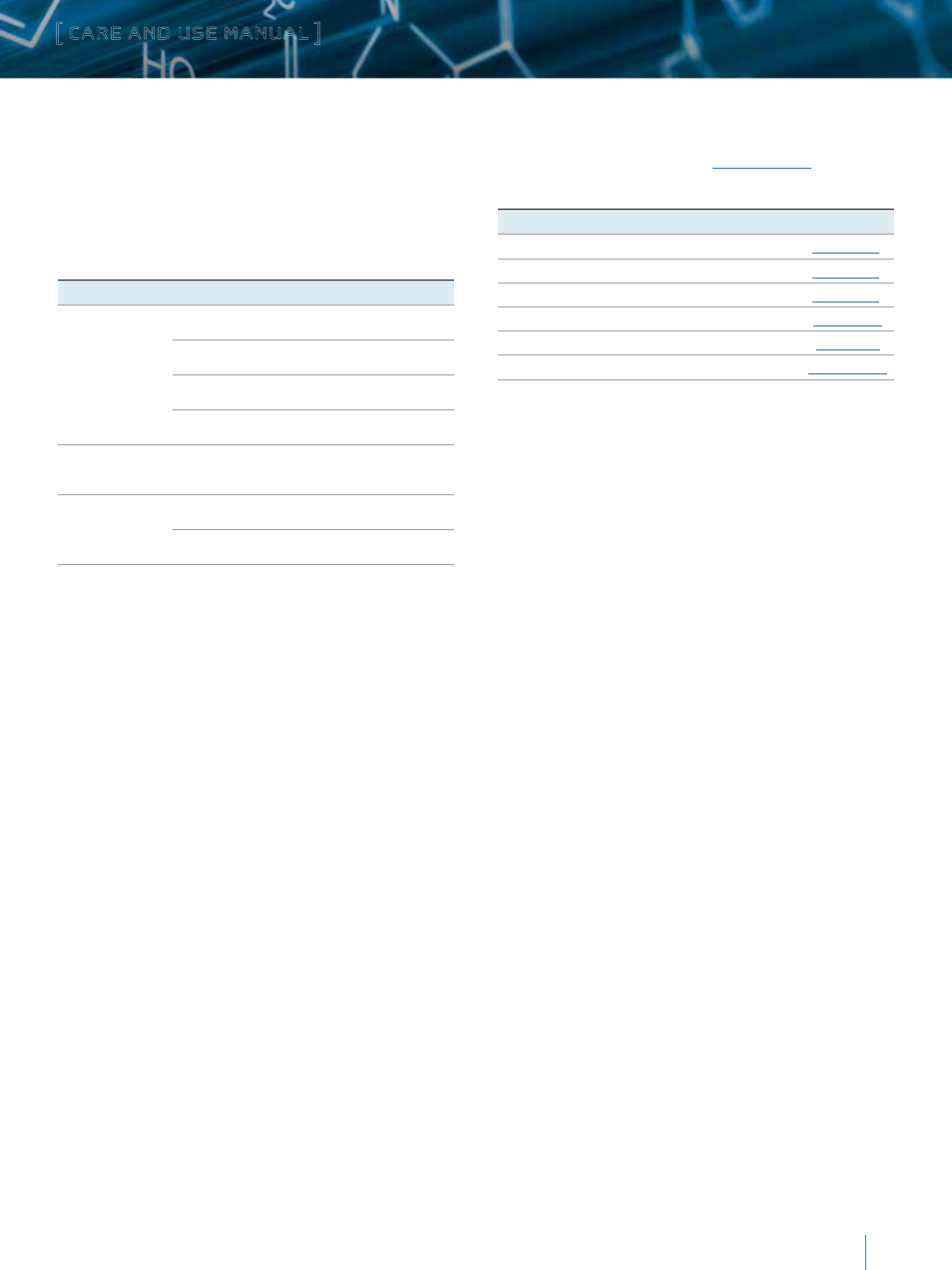

VI. T ROUBLESHOOTING

Table 5 describes solutions to problems that may arise while

using the samplers. Most errors occur as a result of contamination

during sample preparation. To resolve chromatographic problems

not listed, refer to your HPLC system manual.

4

Table 5: Troubleshooting

Symptom

Possible Cause

Solution

High carbonyl values

in sampler blank

Contaminated

acetonitrile

Certify acetonitrile quality

prior to use, see Appendix A.

Contaminated

glassware

Use only pre-cleaned

glassware.

Air contamination

during elution

Prepare sample in

a glove box.

Sampler age and

storage conditions

Replace samplers.

Refrigerate fresh samplers.

High formaldehyde

levels in sampler

blank

Coelution of

formaldehyde with

an impurity

Prepare a fresh mobile

phase or decrease the

acetonitrile content.

Broad peaks

Injection volume

too high

Reduce the

injection volume.

System or

column failure

Consult the HPLC

System manual.

VII. REFERENC ES AND BIBLIOGRAPHY

1. Committee on Aldehydes, Board of Toxicology and

Environmental Hazards, National Research Council,

Formaldehyde and Other Aldehydes; National Academy Press,

Washington, DC, 1981.

2. Tejada, S. B. “Evaluation of Silica Gel Cartridges Coated in

Situ With Acidified 2,4-Dinitrophenylhydrazine for Sampling

Aldehydes and Ketones in Air”, Intern. J. Environ. Chem.

1986, 26, 167-185.

3. Riggins, R.M. “Compendium of Methods for the Determination

of Toxic Organic Compounds in Ambient Air”, U.S.

Environmental Protection Agency Report EPA-600/4-84-041,

U.S. Environmental Protection Agency; Research Triangle Park,

NC, 1984.

4. Guide to Successful Operation of Your LC System; Waters

Corporation, Milford, MA 1991.

5. ASTM Method E411; Standard Test Method for Trace Quantities

of Carbonyl Compounds with 2,4-Dinitrophenylhydrazine.

VIII. ORDERING INFORMATION

Waters Sep-Pak XPoSure Aldehyde Samplers are shipped in boxes

of 20 individually-packaged cartridges. Pouches are supplied for

storage after sampling.

To order, contact your Waters representative, call Waters at

(800) 252-4752 or order online at

.

Table 6: Ordering Information

Product

Part Number

Sep-Pak XPoSure Aldehyde Samplers, 20/box

In-Line Pre-Column Filter

Symmetry C

18

Column, 3.9 x 150 mm

Solvent Filter, PVDF, 47 mm, 0.45 µm, Protein, 100/pkg

Beginners Guide to Liquid Chromatography

Guide to Successful Operation of Your LC System

IX. AP PENDIC ES

a. Appendix A: Measuring Acetontrile Purity

HPLC-grade acetonitrile may contain traces of aldehydes and

ketones, and especially acetone. A concentration of 10 µg/L of

an aldehyde or ketone in the acetonitrile adds 0.1 µg to the blank

values determined for the DNPH-derivatives per cartridge.

If you acetonitrile is unacceptable for your application, contact

your solvent supplier, to purify the acetonitrile. To purify

acetonitrile, distill it from an acidified DNPH solution, using a

procedure analogous to the one described in ASTM Method E411

for the purification of methanol.

5

To measure acetonitrile purity:

1. Clean all glassware by rinsing with acetonitrile and heating

in a 60 °C vacuum oven for at least 30 minutes.

2. Elute a fresh sampler with 3 mL acetonitrile.

3. Within 3 minutes, inject the eluate into the HPLC system to

measure the concentration of DNPH derivatives.

4. Add 1 drop of concentrated HCl to the eluate, and allow to

react at room temperature for 30 minutes.

5. Remeasure the concentration of DNPH derivatives by HPLC.

6. Calculate the difference in the concentration of each DNPH

derivative measured in steps 3 and 5 to yield the contribution

form the acetonitrile.

7. Calculate the percent hydrazone contributed by the acetonitrile

relative to the background level. The value for any hydrazone

should not exceed 25% of its value in the blank.

7

[ CARE AND USE MANUAL ]

Sep-Pak XPoSure Aldehyde Sampler