Care and use manual, D. eluting the derivatives from the sampler, Use hplc-grade water and hplc-grade acetonitrile – Waters Sep-Pak XPoSure Aldehyde Sampler User Manual

Page 4: Waters symmetry, Sep-pak xposure aldehyde sampler

[ CARE AND USE MANUAL ]

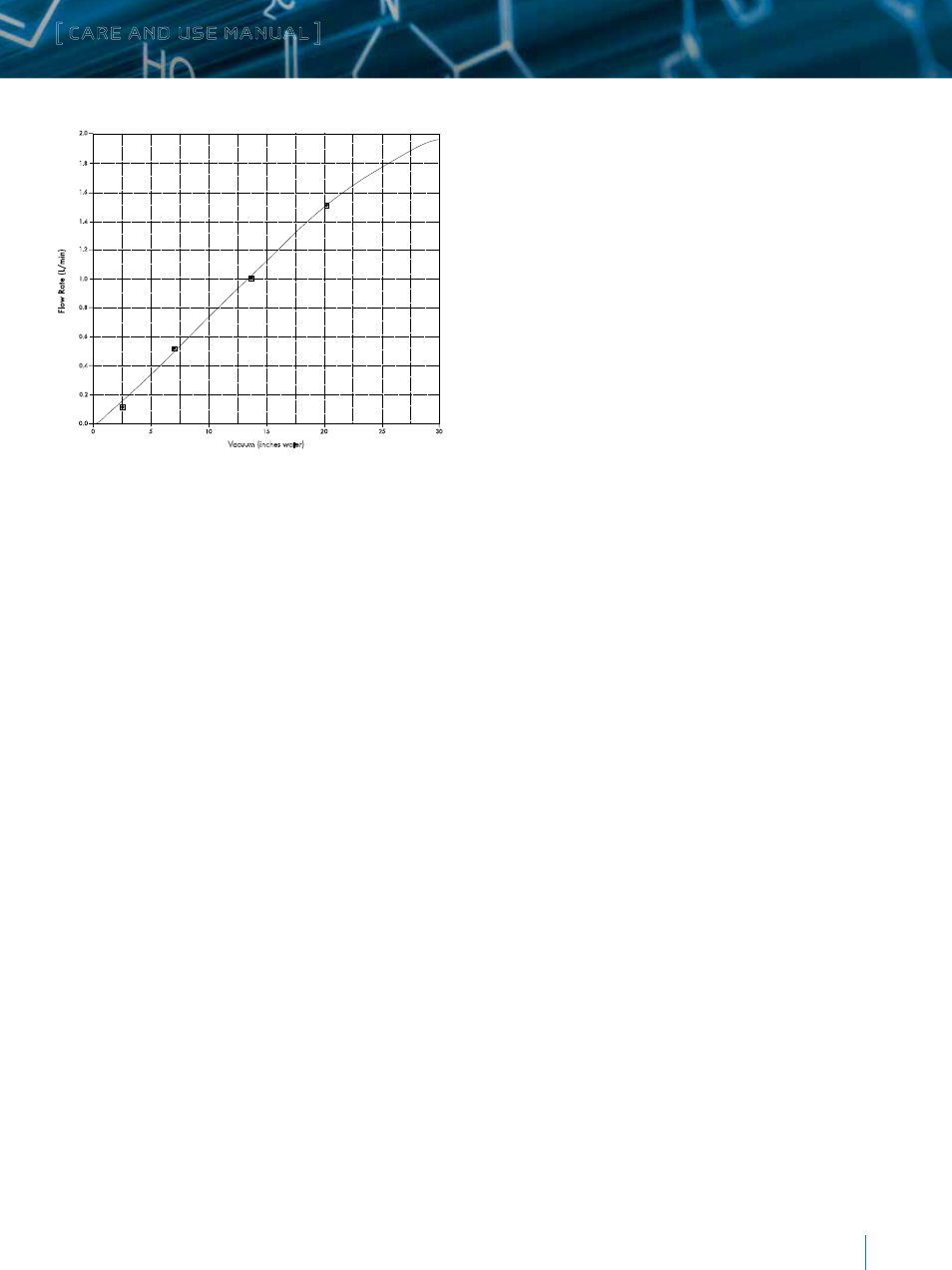

Figure 3: Typical Sampler Backpressure Profile.

Sample Collection – PEL (0.01 to 1.0 ppmv)

To collect the PEL air sample:

1. Calibrate the sampling pump with a representative sampler in

line. Set the flow to 100 mL/min. Figure 3 shows the flow rate

through a sampler versus applied vacuum. Once calibrated,

remove and store this representative sampler for future

calibrations.

2. Take a fresh sample from its pouch. Remove and save the end

cap and plugs.

3. Connect the sampler to a pump with flexible plastic tubing. The

sampler is bidirectional (flow can be in either direction).

4. Draw air for 8 hours, yielding a sample volume of 48 liters.

5. Reseal the sampler with its end cap and plug.

6. Store the sampler in the pouch provided with appropriate

identification. Seal the pouch by folding the edge over twice

and stapling it shut. Avoid exposing the samplers to heat.

A 48 L air sample is sufficient for quantifying formaldehyde in the

range of 0.01 to 1 ppmv. Formaldehyde concentrations lower than

0.01 ppmv in air will require longer sampling times and a larger

air sample. Conversely, formaldehyde concentrations that exceed

1.0 ppmv will require shorter sampling times or reduced sampling

flow rates in order to avoid overloading the sampler and obtaining

nonlinear results.

Note: The maximum recommended sampler capacity is 2.3 µmoles

total carbonyl species. This calculates to 50% of the DNPH consumed.

Contaminated air may contain significant concentrations of other

aldehydes and ketones and the total may exceed the capacity

of the sampling device. Follow the procedure in Appendix C,

Measuring Breakthrough for more information.

d. Eluting the Derivatives from the Sampler

To elute the derivatives from the sampler:

1. Remove the sampler from the stapled pouch.

2. Elute the DNPH derivatives from the sampler with pre-qualified

acetonitrile directly into a 10 mL volumetric flask. Use a flow

rate of <3 mL/min. Higher flow rates (>3 mL/min) can result in

reduced recovery.

3. Cap the volumetric flask and mix by inverting it several times.

4. Analyze the eluate using HPLC.

Note: Since background levels may change during storage, always

compare samples to a blank sampler from the same lot, stored

under the same conditions.

III. ANALYZING T HE DNPH DERIVATIV ES

a. Operating Guidelines

To ensure success in your HPLC analysis:

■

■

Use a pre-column filter between the injector and column.

■

■

Use HPLC-grade water and HPLC-grade acetonitrile.

■

■

Degas the mobile phases by simultaneously applying

vacuum and ultrasound to the mobile phases for 30 seconds.

If you are using a low-pressure mixing gradient system,

sparging with helium may be necessary.

■

■

Waters Symmetry

®

C

18

columns are shipped containing

water/acetonitrile. Before the first analysis, equilibrate the

column with mobile phase at 1.3 mL/min for 10 minutes in

mobile phase or until the baseline is stable. See Table 4 for

separation conditions.

Vacuum (inches water)

25

30

5

15

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

4

[ CARE AND USE MANUAL ]

Sep-Pak XPoSure Aldehyde Sampler