Care and use manual – Waters ACQUITY UPC2 Trefoil Columns User Manual

Page 5

5

[ CARE AND USE MANUAL ]

ACQUITY UPC

2

Trefoil Columns Care & Use

appropriate additive. Additives tend to improve peak shape and

control the retention characteristics of analytes, but can also

impart different selectivities. It is recommended to flush and

remove additives and salts from the column before placing the

column into storage.

d. Pressure

ACQUITY UPC

2

Column hardware and packing materials are

packed and tested to pressures of up to 6,000 psi (414 bar or

41 Mpa).

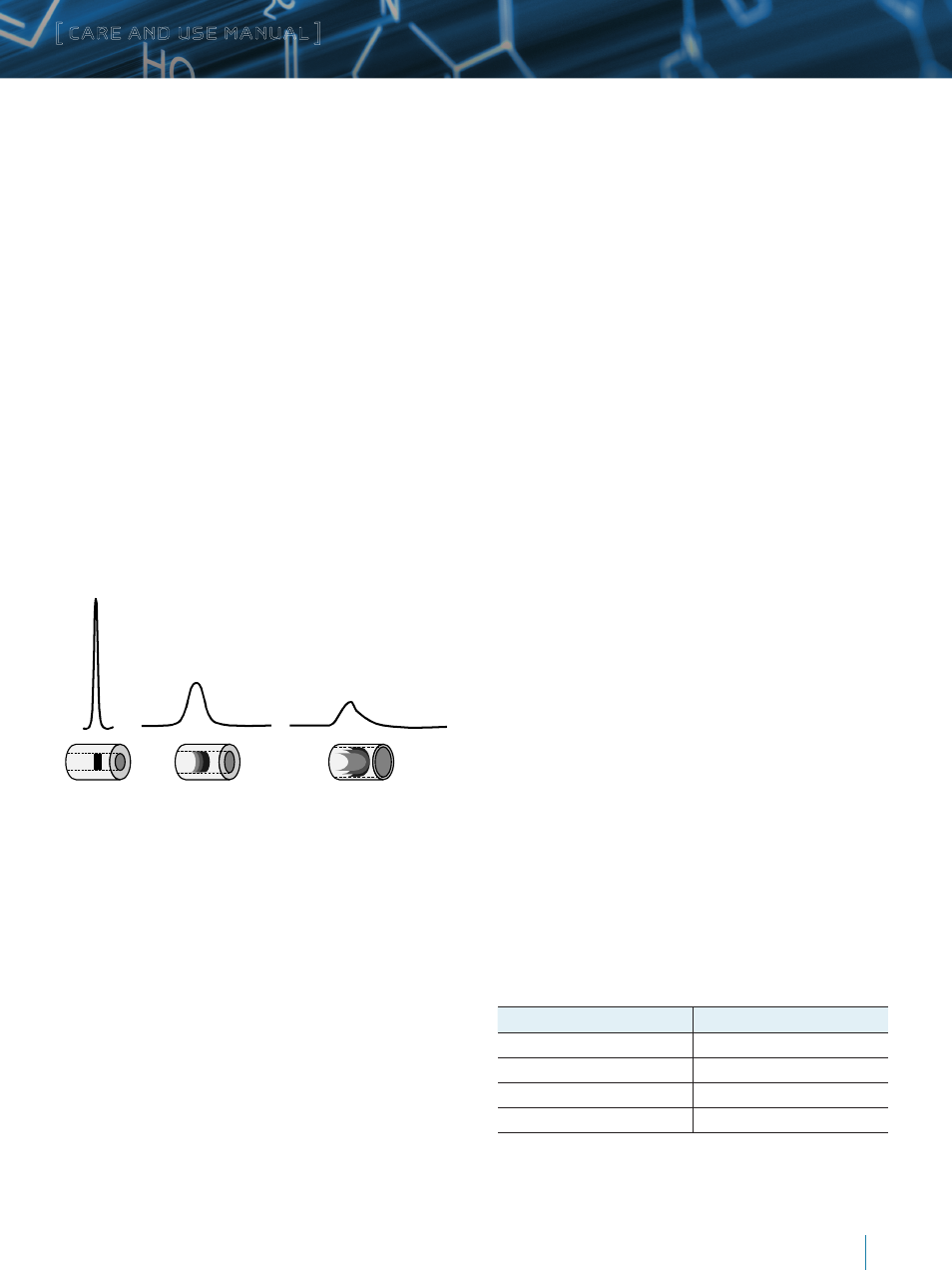

e. Band Spreading Minimization

The ACQUITY UPC

2

System has been designed to minimize band

spreading. Deviation from Waters specified tubing could result

in deterioration of chromatographic performance due to band

spreading induced by inappropriate tubing i.d. Figure 1 shows the

influence of tubing internal diameter on system band spreading

and peak shape. As can be seen, the larger tubing diameter causes

excessive peak broadening and lower sensitivity.

Figure 1: Effect of connecting tubing on system.

IV. T ROUBLESHOOTING

1. One of the most common problems with regards to columns

is incorrect or insufficient priming of the co-solvent/modifier

pump. If no peaks are observed after an injection or unusually

long retention times are observed, check the priming of the

co-solvent/modifier pump first.

2. If you see frosting on the column at the inlet or outlet, tighten

the compression screw on that side. If tightening doesn’t work,

depressurize the system and the column, and then replace the

fitting that is not sealing correctly.

3. If you continue to see frosting on the column, turn off the CO

2

and vent the system. Allow the column to depressurize fully

before disconnecting the inlet or outlet. Please contact your

Waters representative for additional support.

V. COLUMN CLEANING, ADDITIV ES AND STORAGE

Changes in peak shape, peak splitting, shoulders on the

peak, shifts in retention, change in resolution or increasing

backpressure may indicate contamination of the column.

Flushing with high concentrations of organic solvent, taking

care not to precipitate buffers, is usually sufficient to remove

the contaminant. If the flushing procedure does not solve the

problem, purge the column using the following cleaning and

regeneration procedures.

a. Cleaning

Use the cleaning routine that matches the properties of the

samples and/or what you believe is contaminating the column

(see Table 4). Placing the column on an ACQUITY UPLC System

(or HPLC system) will enable the use of a wide range of solvents

to improve cleaning.1 Flush columns with 10 column volumes

of solvent. Increasing column temperature increases cleaning

efficiency. If the column performance is poor after cleaning and

regenerating, call your local Waters office for additional support.

Polar Samples

Non-Polar Samples

1. Methanol

1. Isopropanol

2. Isopropanol

2. Heptane

3. Methanol

3. Isopropanol

4. Mobile Phase

4. Mobile Phase

Table 2: Column Cleaning Sequence.

Diluted/Distorted Sample Band

0.005 inches

0.020 inches

0.040 inches