5rotary deflectors, Inspecting rotary deflectors, Rotary deflectors – MacDon R85 Rotary Disc 16 Foot Pull-Type User Manual

Page 179: Important, Warning, Danger

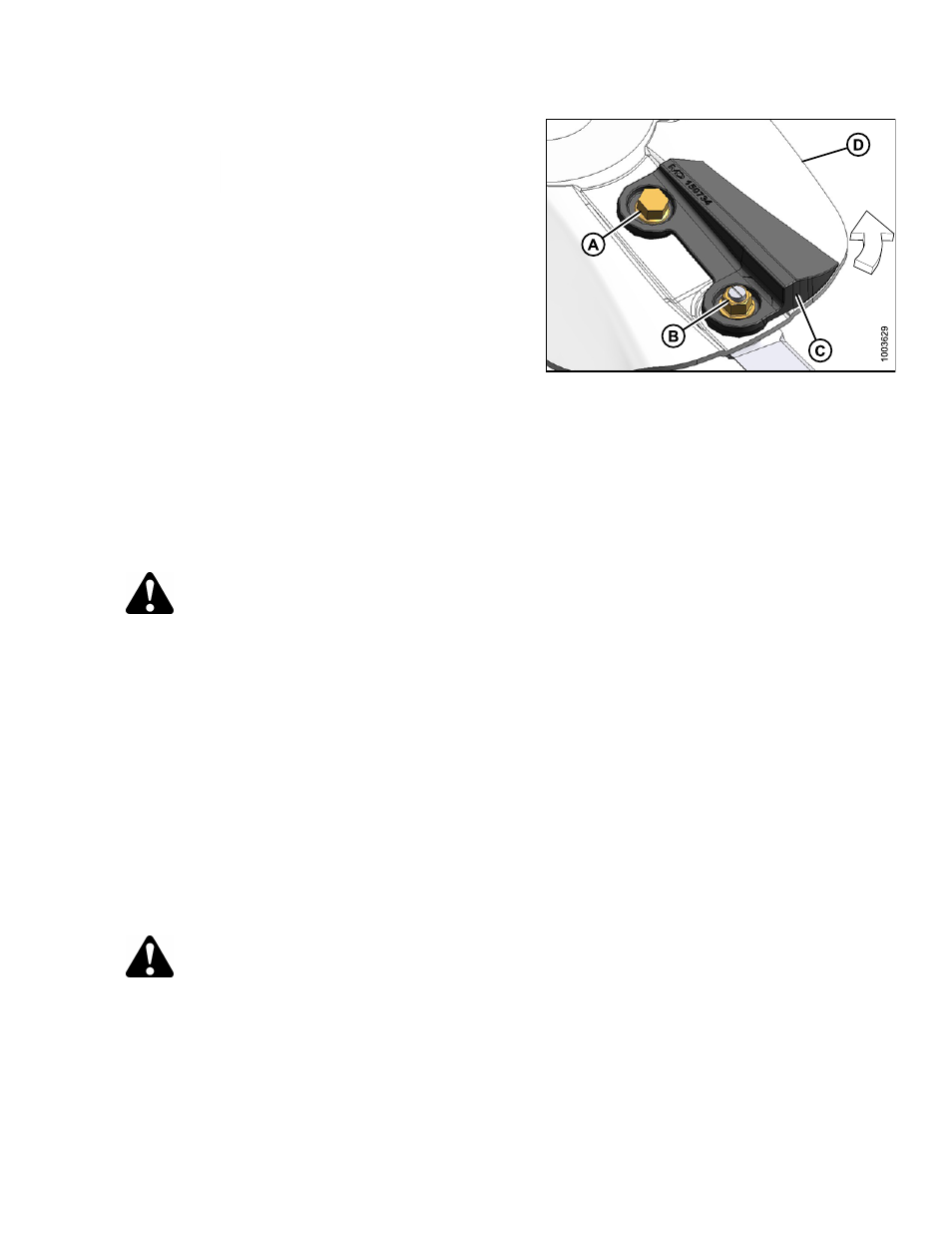

4. Remove bolt and nut (A) and nut (B) and remove

accelerator (C) from disc (D).

IMPORTANT

Do NOT remove cutter blade bolt unless it

or the blade are being replaced.

Repeat for

other accelerator.

5. Locate new accelerator on disc onto existing cutter

blade bolt. Install nut (B).

NOTE: Accelerators are handed for clockwise

or

counterclockwise

operation.

Verify the direction of disc before

installing accelerators.

6. Install hex bolt (A) and nut at inboard hole. Bolt head

faces up.

7. Tighten both nuts to 100 ft·lbf (135 N·m).

8. Repeat for other accelerator.

9. Reinstall disc (D) on spindle. Refer to Section

.

Figure 8.49

10. Remove block of wood (if used).

WARNING

Ensure cutterbar is completely clear of foreign

objects.

These objects can be ejected with

considerable

force

when

the

machine

is

started and may result in serious injury or

machine damage.

11. Close cutterbar doors.

8.7.5 Rotary Deflectors

The rotary cage deflectors are designed to deliver the cut material from the ends of the cutterbar into the auger and

to assist in maintaining an even flow of crop into the conditioner.

Rotary deflectors should be checked daily for damage or wear.

Inspecting Rotary Deflectors

DANGER

Stop engine and remove key from ignition before

leaving operator’s seat for any reason. A child or

even a pet could engage an idling machine.

1. Lower mower conditioner to ground, shut off engine,

and remove key.

169456

169

Rev. D