MacDon R85 Rotary Disc 16 Foot Pull-Type User Manual

Page 144

2. Apply hydraulic system oil to the O-ring.

3. Align the tube or hose assembly. Ensure that flat face

of the mating flange comes in full contact with O-ring.

4. Thread tube or hose nut until hand-tight. The nut

should turn freely until it is bottomed out.

5. Torque fitting further to a given torque value in the table

shown in the opposite column.

NOTE: If applicable, always hold the hex on the

fitting body to prevent unwanted rotation

of fitting body and hose when tightening

the fitting nut.

6. When assembling unions or two hoses together, three

wrenches will be required.

7. Check the final condition of the fitting.

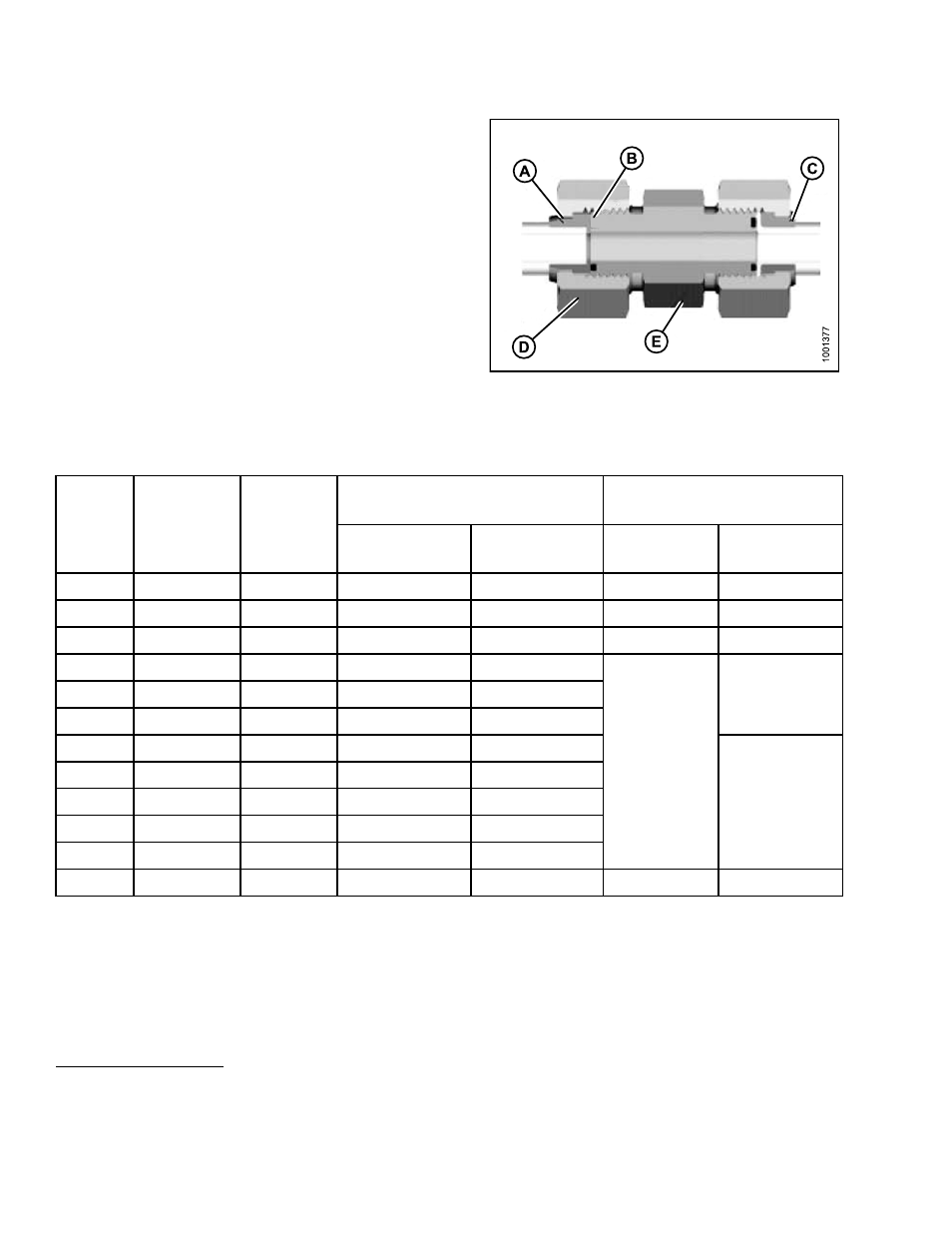

Figure 8.11

A - Brazed sleeve

B - O-ring

C - Two piece sleeve

D - Nut

E - Fitting body

Table 8.12 O-Ring Face Seal (ORFS) Hydraulic Fittings

Torque value

4

Flats from finger tight

(FFFT)

5

SAE

No.

Thread

size (in.)

Tube O.D.

(in.)

ft·lbf

N·m

Tube Nuts

Swivel &

Hose

3

6

3/16

–

–

–

–

4

9/16

1/4

11–12

14–16

1/4–1/2

1/2–3/4

5

5/16

–

–

–

–

6

11/16

3/8

18–20

24–27

8

13/16

1/2

32–35

43–47

10

1

5/8

45–51

60–68

1/2–3/4

12

1-3/16

3/4

67–71

90–95

14

1-3/16

7/8

67–71

90–95

16

1-7/16

1

93–100

125–135

20

1-11/16

1-1/4

126–141

170–190

24

2

1-1/2

148–167

200–225

1/4–1/2

1/3–1/2

32

2-1/2

2

–

–

–

–

4.

Torque values and angles shown are based on lubricated connection, as in reassembly.

5.

Always default to the torque value for evaluation of adequate torque.

6.

O-ring face seal type end not defined for this tube size.

169456

134

Rev. D