2adjusting the roll timing, Adjusting the roll timing, Caution – MacDon R85 Rotary Disc 16 Foot Pull-Type User Manual

Page 102

OPERATING THE MOWER CONDITIONER

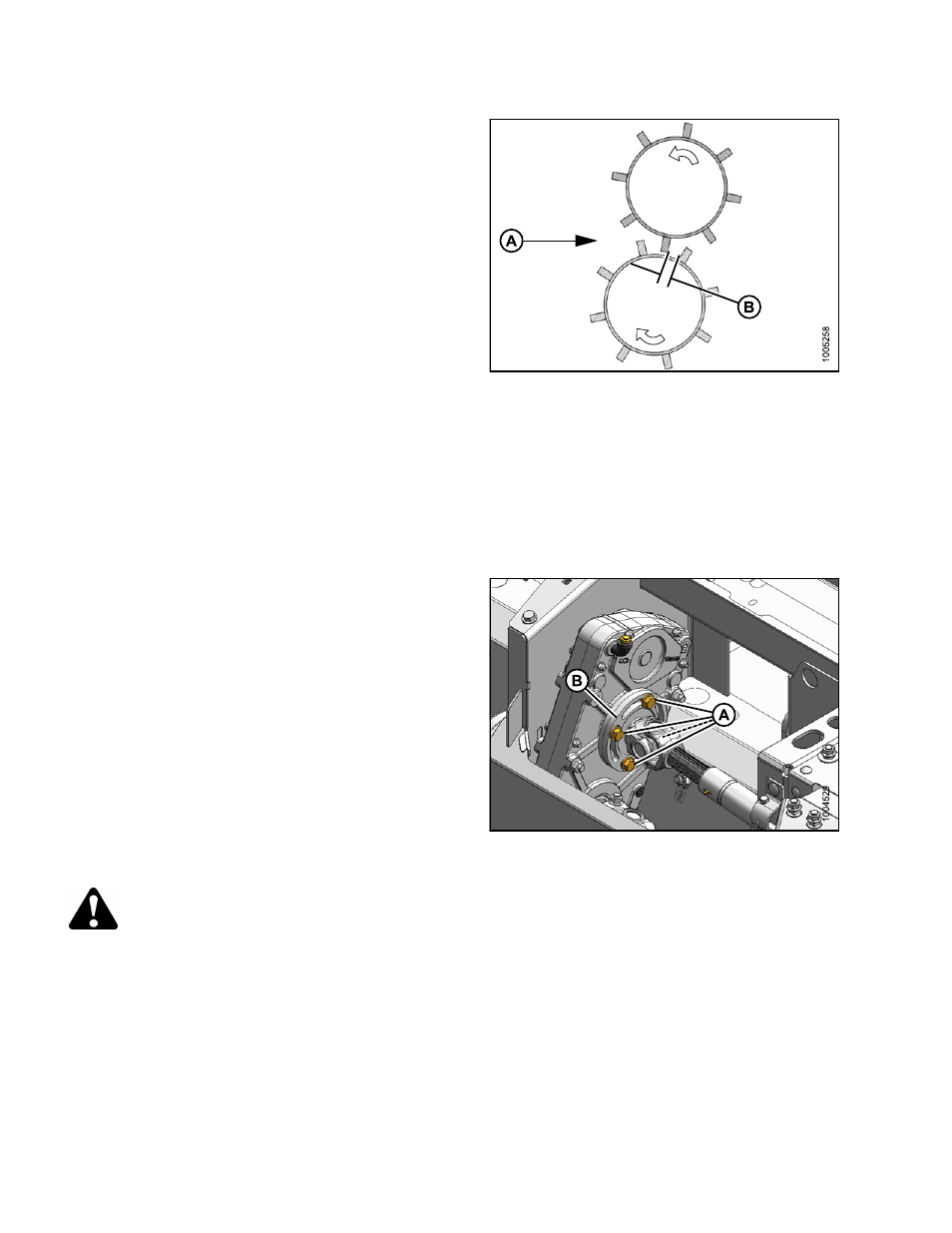

3. Examine roll timing at each end of the rolls with the

mower conditioner fully lowered. Each steel bar on one

roll should be centered between two bars of the other

roll so that distance (B) is approximately equal on both

sides of the bar. Refer to Section

.

Figure 7.11

A – crop flow

B – roll timing distance

7.4.2 Adjusting the Roll Timing

Follow these steps to adjust the roll timing (if necessary):

1. Loosen four bolts (A) in slots of yoke plate (B) on upper

roll universal shaft.

2. Manually rotate upper roll until it stops. Make a mark

on yoke flange to align with the center of one of the bolt

heads (A).

3. Manually rotate upper roll in opposite direction until it

stops. Make a second mark on yoke flange to align

with the bolt.

4. Determine the center between the two marks and mark

a third line on the yoke flange.

5. Rotate the upper roll until the bolt lines-up with the

third line.

6. Tighten bolts (A) to secure the position. Torque to

70 lbf·ft (95 N·m).

CAUTION

To ensure gauge is not forcibly ejected from rolls

when machine is started, ensure gauge is securely

re-attached to frame.

Figure 7.12

169456

92

Rev. D