Caution – MacDon A40-D User Manual

Page 174

SECTION 7 MAINTENANCE AND SERVICING

169000 / 169040

172

Revision E

7.14 WHEELS, TIRES, AND HITCH:

PULL-TYPE

CAUTION

To avoid personal injury, before servicing

header/mower conditioner or opening drive

covers, follow procedures in Section 7.1

PREPARATION FOR SERVICING.

7.14.1 Wheel Bolts

IMPORTANT

Check and tighten wheel bolts after the

first hour of operation, and every

100 hours thereafter.

IMPORTANT

Whenever a wheel is removed and

re-installed, check torque after one hour of

operation. Maintain 120 ft·lbf (160 N·m)

torque.

7.14.2 Wheel Removal

a. Lower header to the ground.

b. Retrieve jack (5000 lb capacity) from storage

position on APT.

c. Position jack on mount provided on frame leg as

shown, and raise tire just off the ground. Place

block under frame leg.

d. Remove

wheel

bolts.

e. Remove

wheel.

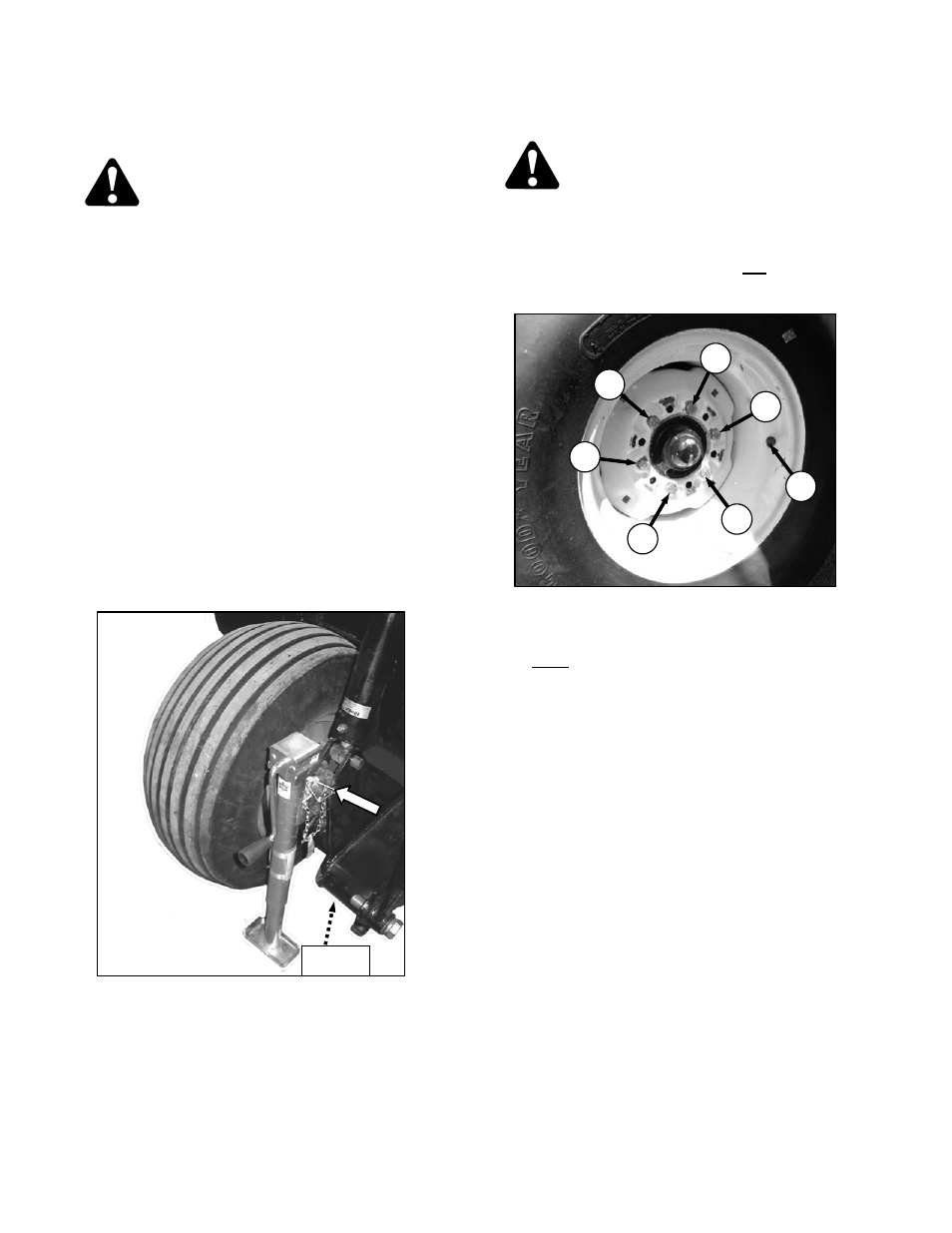

7.14.3 Wheel Installation

CAUTION

When installing wheel be sure to use the

holes that are countersunk to match bolt

head profile.

The uncountersunk holes do not seat the

bolts correctly.

IMPORTANT

Follow proper bolt tightening sequence

shown. Be sure valve stem (A) points

away from wheel support.

a. Position wheel on spindle, and install bolts.

Partially tighten.

b. Remove blocks, and raise jack until tire contacts

the ground.

c. Torque bolts to 120 ft·lbf (160 N·m) in

accordance with tightening sequence shown.

d. Raise jack completely, remove from leg and

store on APT.

1

2

3

4

5

6

A

BLOCK