MacDon A40-D User Manual

Page 144

SECTION 7 MAINTENANCE AND SERVICING

169000 / 169040

142

Revision E

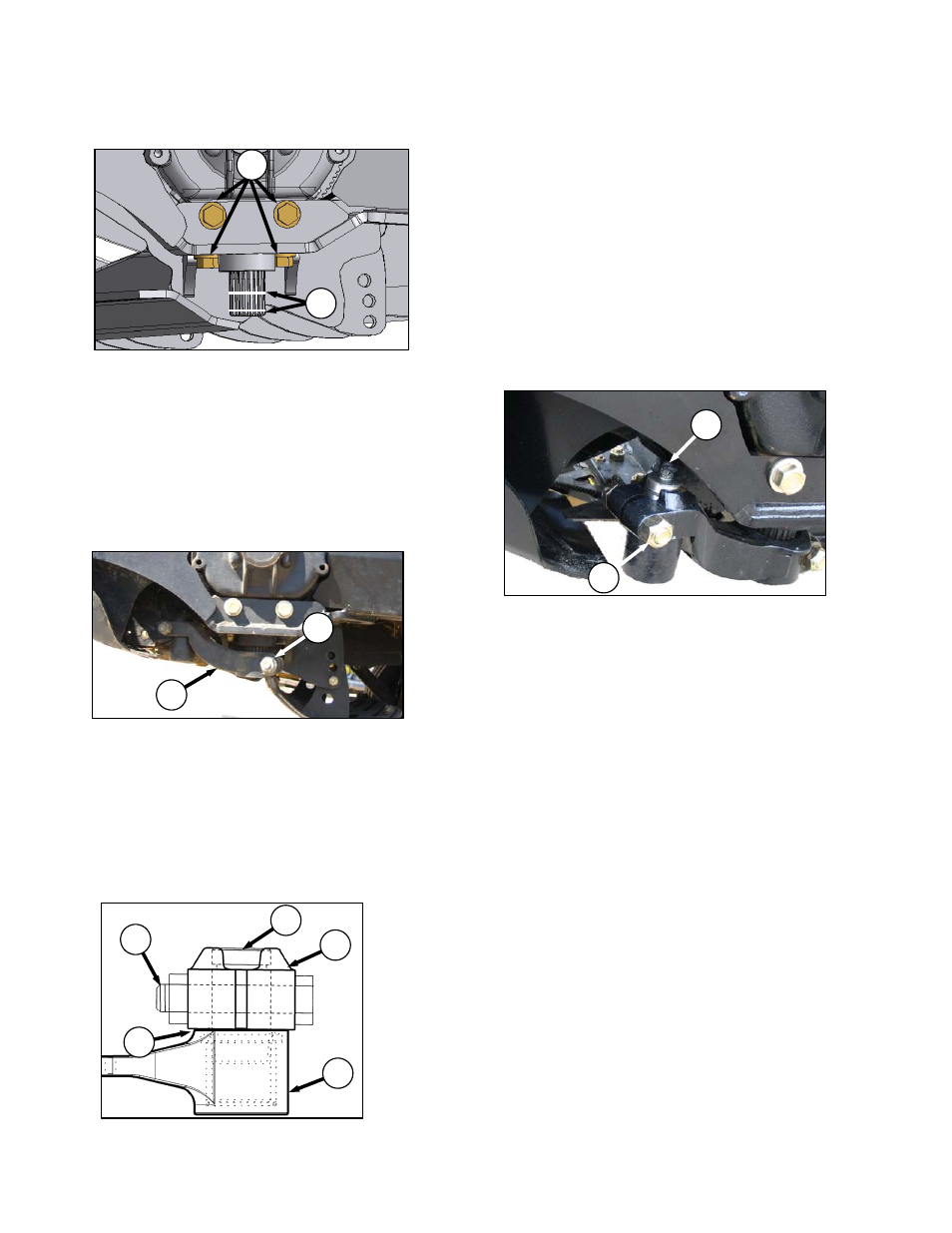

7.8.13.3 Sickle Drive Box Installation

a. Position sickle drive box as shown, and install

four bolts (A). Torque side bolts, and then

torque bottom bolts to 200 ft·lbf (270 Nm).

IMPORTANT

Use only Grade L9 bolts and flat washers.

b. Apply Loctite® #243 adhesive (or equivalent) in

two bands (B) around shaft as shown, with one

band at end of shaft, and one band

approximately mid-way.

c. Slide pitman arm (C) onto sickle drive box output

shaft.

d. Rotate sickle drive box pulley to ensure pitman

arm just clears frame to ensure proper

placement on splines. Remove arm (C), and

re-position on splines as required.

e. Rotate sickle drive box pulley to locate pitman

arm at furthest outboard position.

f. Slide arm (C) up or down on shaft until it just

contacts sickle head (D) (0.010 in. [0.25 mm])

gap.

g. Install bolt (E) and nut, and torque to 160 ft·lbf

(217 N·m).

h. Align sickle head (D) with pitman arm (C).

i.

Install sickle head pin (F) in pitman arm (C) and

tap it down into the sickle head, ensuring pin is

bottomed out in the sickle head.

j.

Tap underside of the sickle head until the pin is

flush with the upper face of the pitman arm (C).

k. Carefully adjust to achieve a 0.010 in. (.25 mm)

gap at (G) with the sickle laying flat on the first

few guards.

l.

Replace bolt (H) and nut.

m. Tighten nut to 160 ft·lbf (220 N·m).

n. Replace grease zerk (J) in pin.

o. Install drive belt onto sickle drive box pulley and

tighten. Refer to one of the following sections,

depending on your equipment:

Section 7.8.9.1 Tension Adjustment: Sickle

Drive Belt - A30-S

Section 7.8.10.1 Tension Adjustment:

LH Sickle Drive Timing Belt - A30-D

Section 7.8.10.4 Tension Adjustment:

RH Sickle Drive Timing Belt - A30-D

Section 7.8.11.1 Tension Adjustment:

LH Sickle Drive Belts - A40-D

Section 7.8.11.4 Tension Adjustment:

RH Sickle Drive Belt - A40-D

A

B

C

E

J

H

C

F

H

G

D