MacDon A40-D User Manual

Page 129

SECTION 7 MAINTENANCE AND SERVICING

169000 / 169040

127

Revision E

7.8.8.2

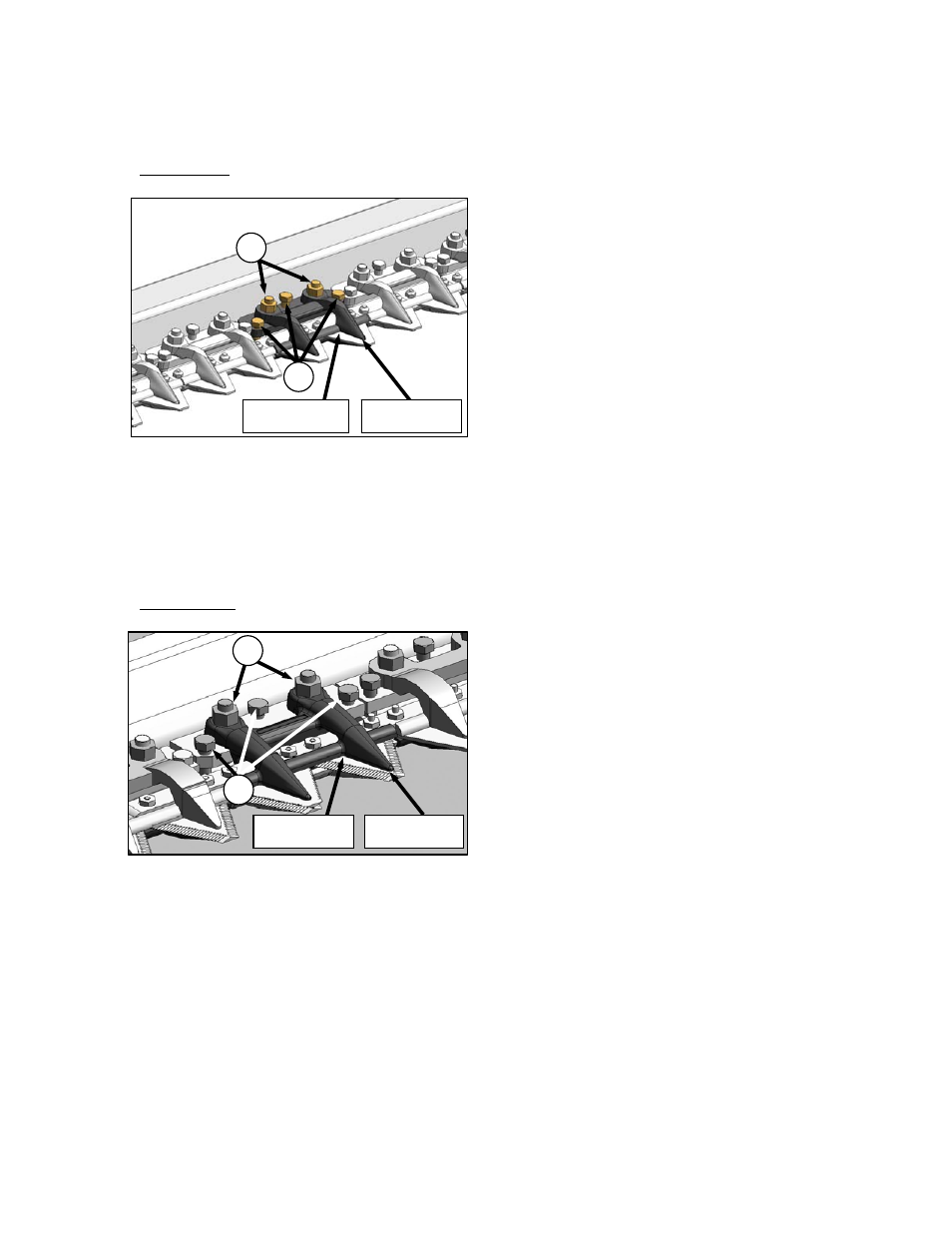

Sickle Hold-Down Adjustment: Stub

Guards

Single Knife

a. Torque nuts (E) to 35 ft·lbf (46 N·m).

b. Turn adjuster bolts (F). Using a feeler gauge,

clearance from hold-down to sickle section

should be 0.004–0.016 in. (0.1–0.4 mm) at the

guard tip, and 0.004–0.040 in. (0.1–1.0 mm) at

rear of guide.

c. Torque nuts (E) to 53 ft·lbf (72 N·m).

Double Knife

a. Torque nuts (G) to 35 ft·lbf (46 N·m).

b. Turn adjuster bolts (H). Using a feeler gauge,

clearance from hold-down to sickle section

should be 0.004–0.016 in (0.1–0.4 mm) at the

guide tip, and 0.004–0.040 in. (0.1–1.0 mm) at

rear of guide.

c. Torque nuts (G) to 53 ft·lbf (72 N·m).

d. After adjusting all hold-downs, run header at a

low engine speed, and listen for noise due to

insufficient clearance. Insufficient clearance will

also result in overheating of the sickle and

guards.

0.004

–

0.040 in.

(0.1

–

1.0 mm)

0.004

–

0.016 in.

(0.1

–

0.4 mm)

E

F

0.004

–

0.016 in.

(0.1

–

0.4 mm)

0.004

–

0.040 in.

(0.1

–

1.0 mm)

G

H