Snap-loc 24, Installation of panel, Cont.) – Metal Sales Snap-Loc 24 Installation User Manual

Page 37

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

SNAP-LOC 24

36

INSTALLATION OF PANEL

(CONT.)

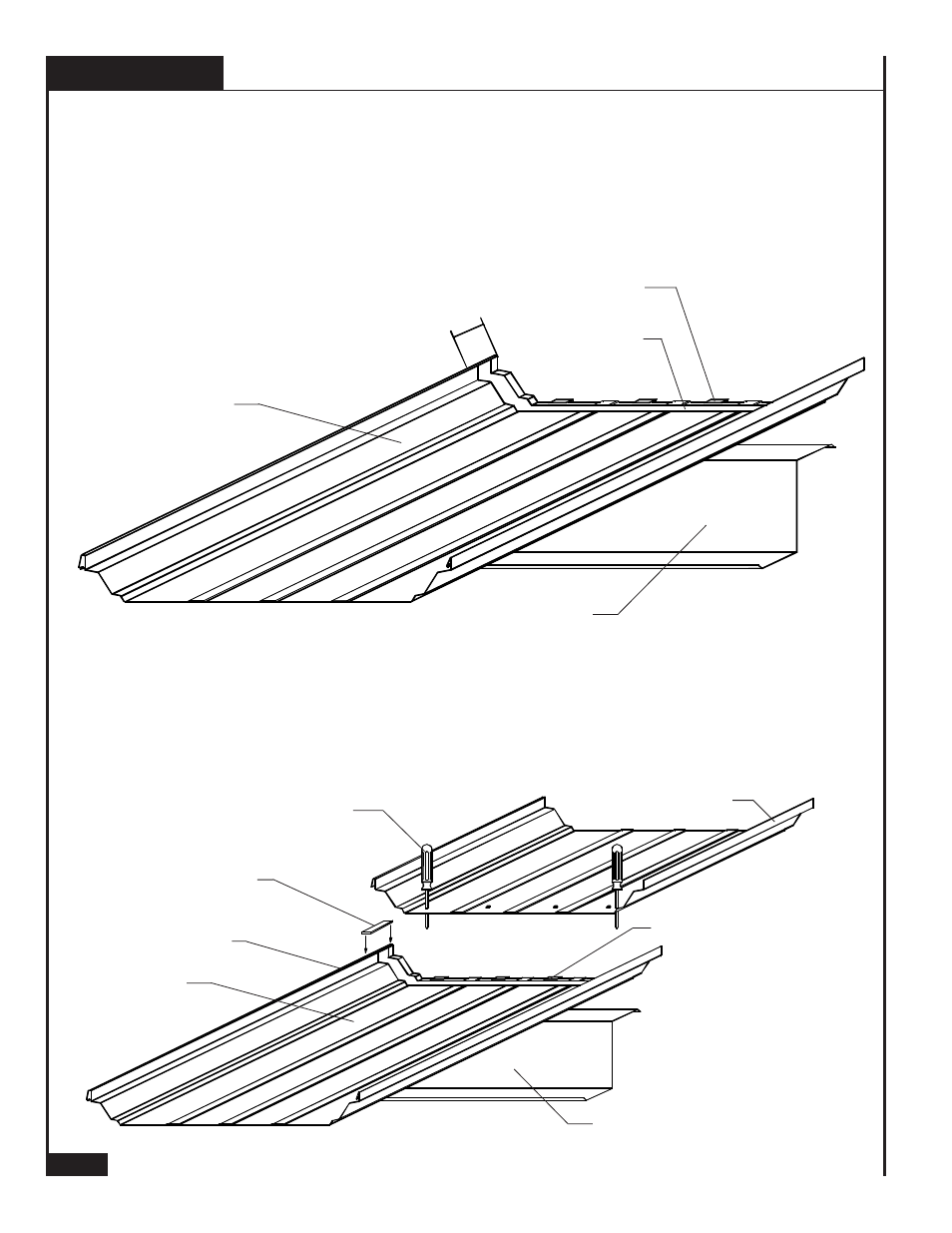

ENDLAP PURLIN

2

1

/

8

"

COMPRESSION PLATE

ENDLAP PURLIN

FEMALE LEG

MALE LEG

ENDLAP PAD

2. The male and female side of both ends of the eave panel are factory notched 2

1

/

8

" to allow the

peak panel to nest inside the eave panel.

3. Slide the Compression Plate on to the end of the eave panel. The tab on the Compression Plate

should engage the panel. A portion of the Compression Plate should rest on the purlin flange.

4. Apply an Endlap Pad on the endlap end of the eave panel down the male leg, across the panel,

and up the female leg

1

/

4

" from the end of the panel. Center the Endlap Pad over the factory

punched holes. Do not stretch the Endlap Pad as this will cause gaps in the pads coverage.

5. Apply a 2

1

/

8

" pig tail of Double Bead Tape Sealant over the factory notched section of the

Snap-Loc 24 panel legs.

6. Place two hole punches in the peak panel in the outer most factory punched holes. Push punches

through endlap pad and factory punched holes in compression plates, thus aligning panels and

lapping the proper 2

1

/

8

".

7. Nest the peak panel into the eave panel. It may be necessary to bow the center of the peak panel

slightly upward to allow ease in aligning the two panels.

EAVE PANEL

COMPRESSION PLATE

HOLE PUNCH

EAVE PANEL

PIG TAIL OF DOUBLE

BEAD TAPE SEALANT