Snap-loc 24 installation of panel – Metal Sales Snap-Loc 24 Installation User Manual

Page 36

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

35

SNAP-LOC 24

INSTALLATION OF PANEL

(CONT.)

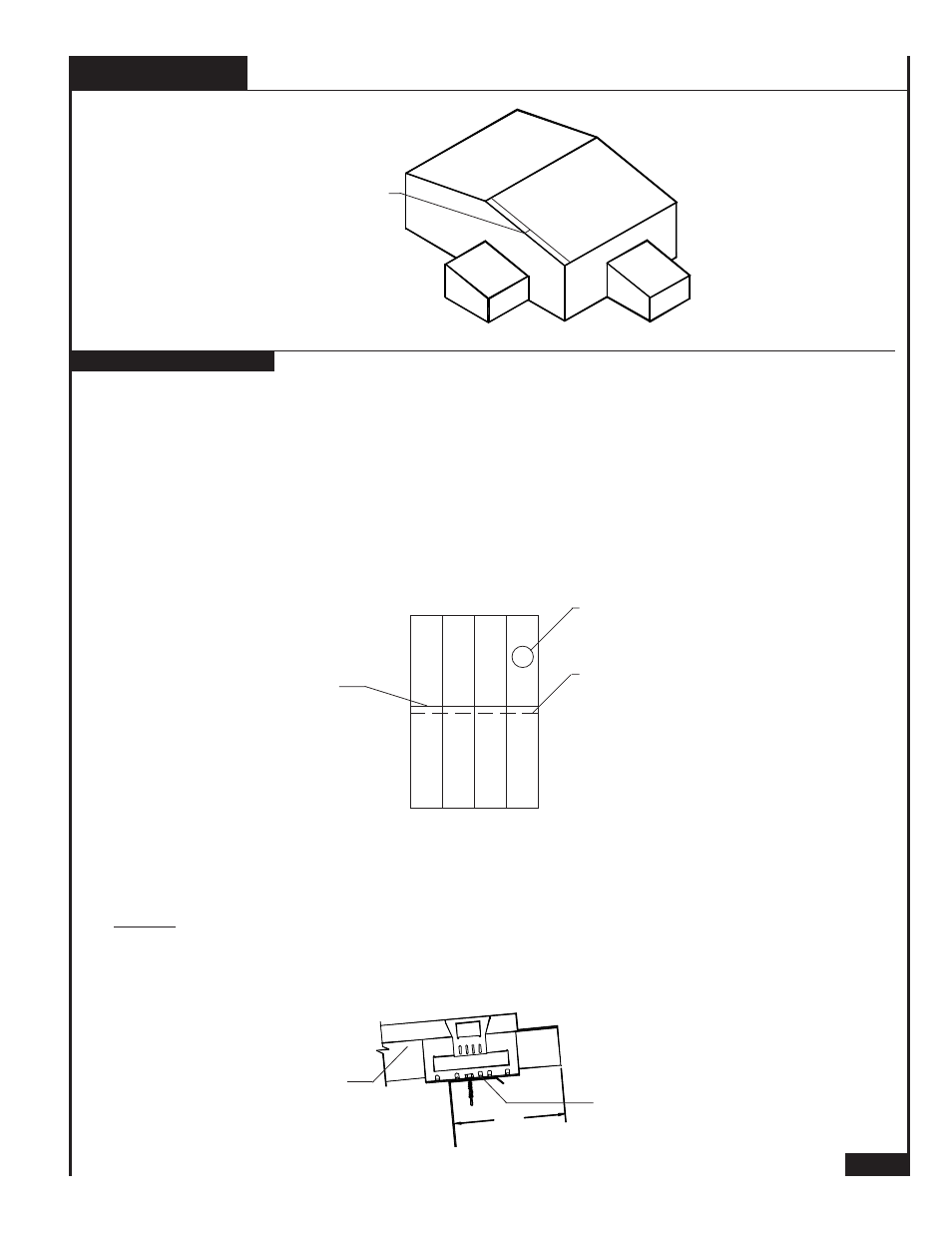

ENDLAPPING OF PANEL

ENDLAP PURLIN

ENDLAPPING OF

SNAP-LOC 24 PANEL

If required, Snap-Loc 24 panels can be endlapped for longer panel runs.

Factory notching and punching is standard on all Snap-Loc 24 panels. This eliminates material

buildup at endlaps and allows easy alignment of panels and accessories.

It is critical that the purlins or joists at the ridge and endlaps be located exactly as detailed and

that they are straight from rafter to rafter. Any mislocation or bowing of these members can

cause the fasteners at the endlaps to loosen as the panels expand and contract.

Panel runs with endlaps must be fastened to the substructure at the eave.

Fasteners used at the endlaps must not penetrate the framing members, as this will restrict the

system's ability for thermal movement.

Placement of endlaps must be continuous.

STEPS

1. The eave panel when installed should overhang from the web of the endlap purlin by 6". This

dimension must be verified. If the panel overlaps the web of the endlap purlin by a dimension

other than 6", verify that the eave overhang dimension is correct.

The following procedures are for installing two (2) panels from eave to peak. The same

procedures apply when installing more than two panels from eave to peak.

2

4

6

1

3

5

7

8

EAVE

PEAK

PANEL

ENDLAPS

IN-LINE ENDLAPPING

ENDLAP

PURLINS

PANEL INSTALLATION

SEQUENCE

6"

SNAP-LOC 24 PANEL