Snap-loc 24, Fastener installation – Metal Sales Snap-Loc 24 Installation User Manual

Page 14

SNAP-LOC 24

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

13

FASTENER INSTALLATION

TECHNIQUE

TO PREVENT WOBBLING - Make sure fastener head is completely engaged in the socket. If the head

does not go all the way in the socket - tap the magnet deeper into the socket to allow full head engage-

ment. Metal chips will build up from drilling and should be removed from time to time.

PROTECT DRILL POINT - Push only hard enough on the screw gun to engage clutch. This prevents

excess friction and burn out of the drill point. Correct pressure will allow screw to drill and tap without

binding.

DRILLING THROUGH SHEET AND INSULATION - Ease up on pressure when drilling through insulation

to avoid striking the purlin or girt with the point - apply more pressure after drill point contacts purlin

or girt.

DRILLING THROUGH PURLIN OVERLAPS - Drilling through lapped purlins requires extra care. Exces-

sive voids between purlins sometimes damages drill points and two self drillers might be necessary to

complete the operation. It is sometimes advantageous to predrill.

RECOMMENDED TOOL TYPE - Use depth locating nose or adjustable clutch on screw gun to prevent

overdrilling and strip out.

DO NOT USE IMPACT TOOLS OR RUNNERS.

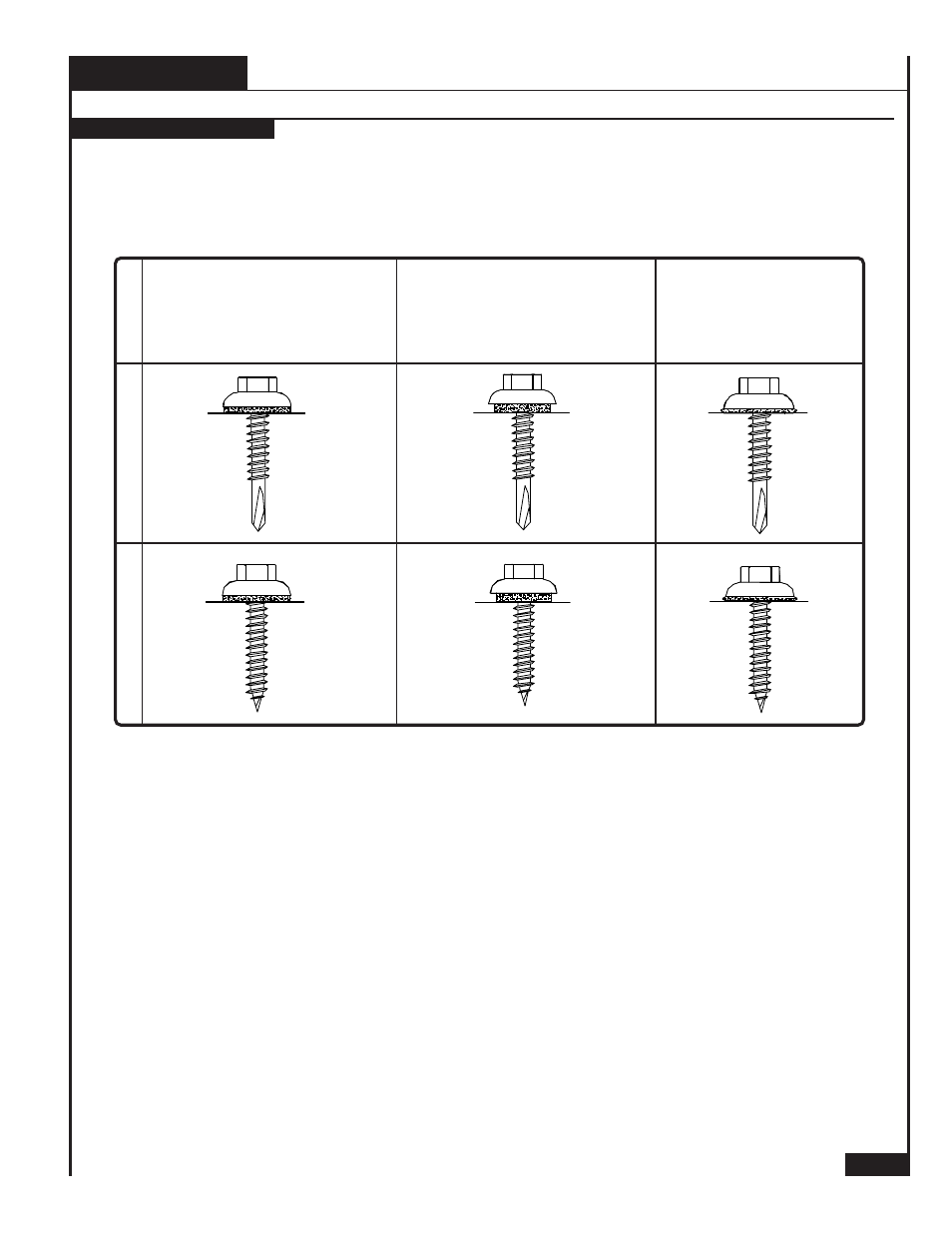

SEATING THE WASHER - Apply sufficient torque to seat the washer - do not overdrive the fastener.

TOO LOOSE

Sealing material is not visible;

not enough compression to

seal properly.

CORRECT

Sealing material slightly visible

at edge of metal washer.

Assembly is watertight.

TOO TIGHT

Metal washer deformed;

sealing material pressed

beyond washer edge.

SELF DRILLER

WOODSCREW