Snap-loc 24, Design / installation considerations – Metal Sales Snap-Loc 24 Installation User Manual

Page 17

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

SNAP-LOC 24

16

SYSTEM EXPANSION / CONTRACTION

CAUTION

Use extreme care when working next to insulation. The insulation will provide a

false sense of security by hiding the view of the ground below the insulation.

SNAP-LOC 24 PANEL

Steel roofing panels are subject to dimensional changes after installation due to exposure to varying

temperatures. The greatest influence is solar energy. Steel roofing absorbs various amounts of heat

depending upon color, finish, angle of exposure, and time of exposure.

The relationship of ambient temperature to building structural temperature must be considered when

designing a Snap-Loc 24 roof system. The floating clips for the Snap-Loc 24 panels are designed for

expansion and contraction of the panels in the longitudinal direction. Lateral expansion and contrac-

tion is accomodated by the configuration of the panel cross section and causes negligible panel

movement.

When the total length of panel run exceeds the capability of the floating clips to accomodate the

thermal movement, expansion joints must be designed into the structure.

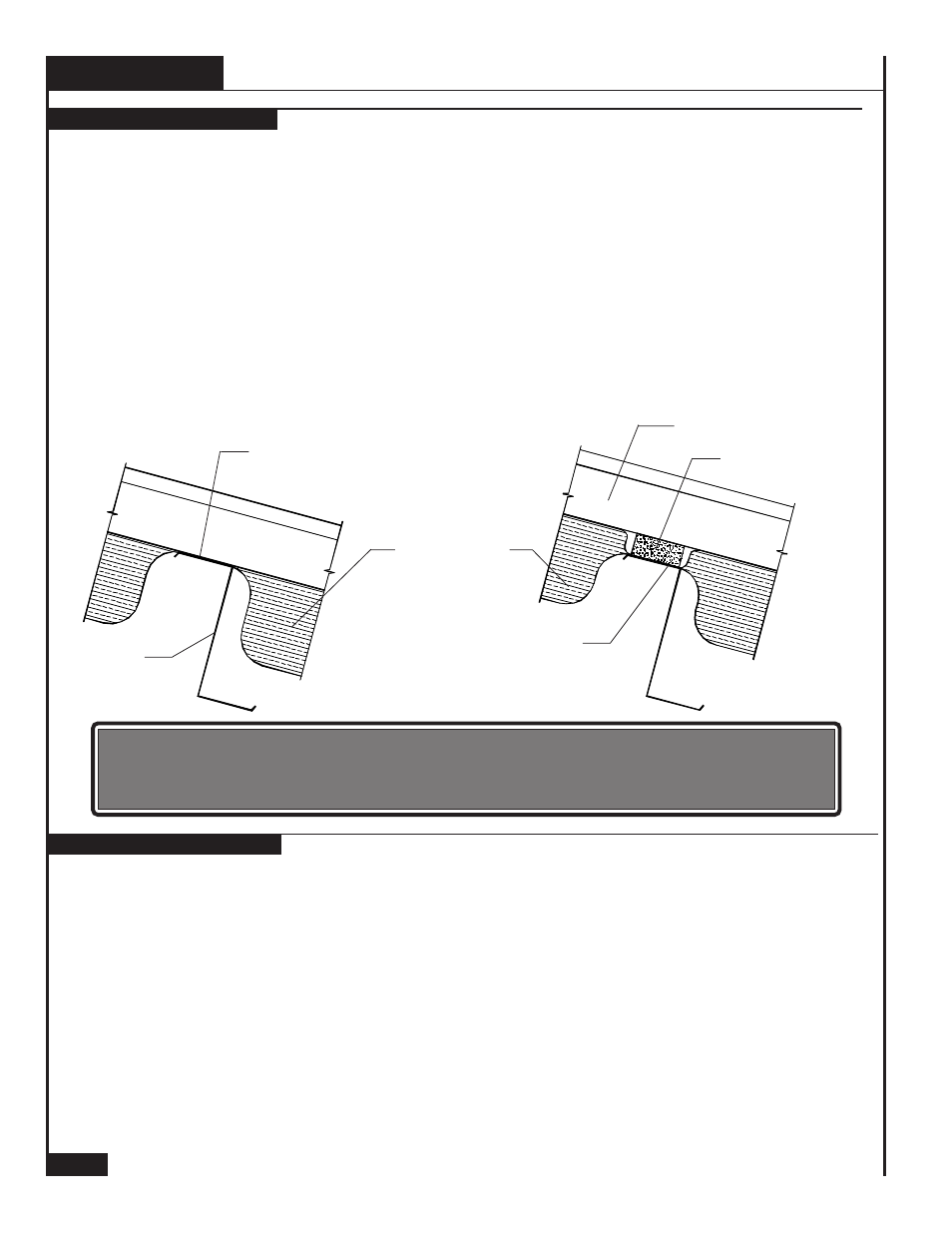

INSULATION

In most cases insulation is installed directly under the roof panels. Insulation is recommended on all

applications to act as a sound barrier, prevent condensation, and increase insulating value of a roof

system. Roof panels installed over open framing without insulation will cause excessive roof noise.

It is recommended that either urethane thermal blocks or 1

1

/

2

" blanket insulation be used as illustrated

to minimize noise potential.

Many different types of insulation can be used with the metal roof panels. Blanket, batt, rigid, and

reflective insulation are just a few. Please contact your insulation supplier for specific recommenda-

tions on type of insulation, vapor barriers, and installation procedures.

When applying a compressable type of insulation over open framing members, rigid thermal blocks

can be used to help eliminate heat lost at purlin locations. See chart on page 17 for available Thermal

Block systems.

DESIGN / INSTALLATION CONSIDERATIONS

(CONT.)

AREA OF LEAST RESISTANCE

TO HEAT LOSS

PURLIN

COMPRESSIBLE

INSULATION

RESISTANCE TO HEAT

LOSS IS INCREASED

THERMAL BLOCK