Snap-loc 24, Field cutting and touch-up – Metal Sales Snap-Loc 24 Installation User Manual

Page 26

SNAP-LOC 24

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

25

FIELD CUTTING AND TOUCH-UP

FIELD CUTTING

TOUCH-UP PAINT

Tin snips or a "nibbler" type electric tool are recommended for field cutting Snap-Loc 24 panels.

Cutting the steel generates slivers or metal chips. These slivers and metal chips must be immediately

removed from the Snap-Loc 24 panels because they will damage the finish and shorten the life of the

product.

One method of preventing this problem is to flip the Snap-Loc 24 panels over when cutting. This

allows the slivers and metal chips to be brushed from the back side and avoids damaging the paint

on the top side of the panels.

When cutting Snap-Loc 24 panels, goggles must be worn for eye protection.

CAUTION

All product surfaces should be free of debris at all times. Installed surfaces should be

wiped clean at the end of each work period. Never cut panels over metal surfaces.

Metal shavings will rust on the surface, voiding the warranty.

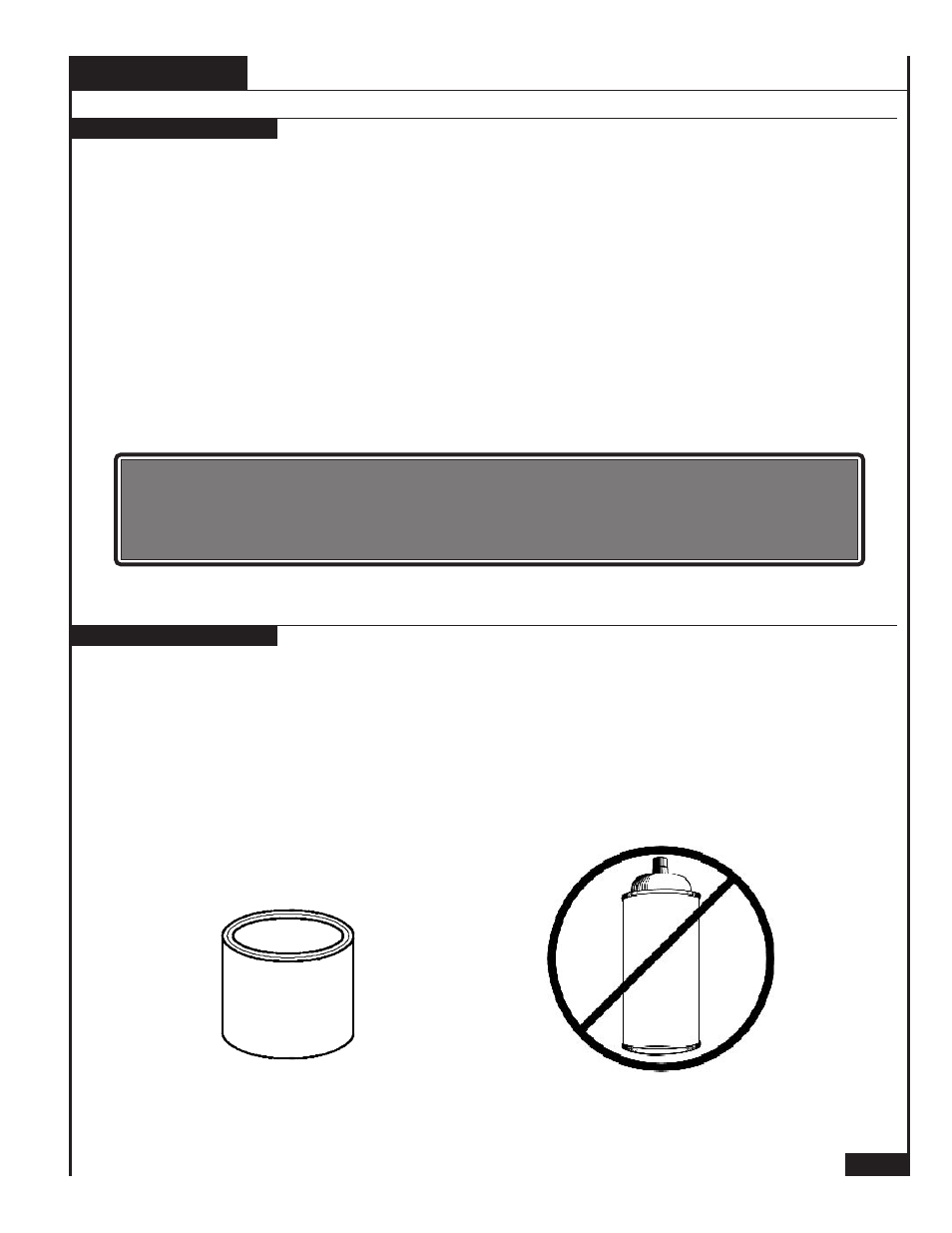

All painted panels and flashings have a factory applied baked on finish. Handling and installing panels

may result in some small scratches or nicks to the paint finish. Touch-up paint is available in matching

colors from Metal Sales. It is recommended that a small brush be used to apply touch-up paint to those

areas that are in need of repair. Touch-up paint does not have the superior chalk and fade resistance of

the factory applied paint finish and will normally discolor at an accelerated rate. Aerosol paint should

not be used because of the overspray that may occur. Due to accelerated fade rate, touch-up paint

should be applied sparingly.