Snap-loc 24, Design / installation considerations – Metal Sales Snap-Loc 24 Installation User Manual

Page 20

SNAP-LOC 24

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

19

DESIGN / INSTALLATION CONSIDERATIONS

(CONT.)

If panel endlapping is required, endlaps are to be applied in one continuous line. This allows the cinch

straps to complete full coverage of the Snap-Loc 24 panel. See page 35-37

ENDLAP

PURLIN

2

4

6

1

3

5

8

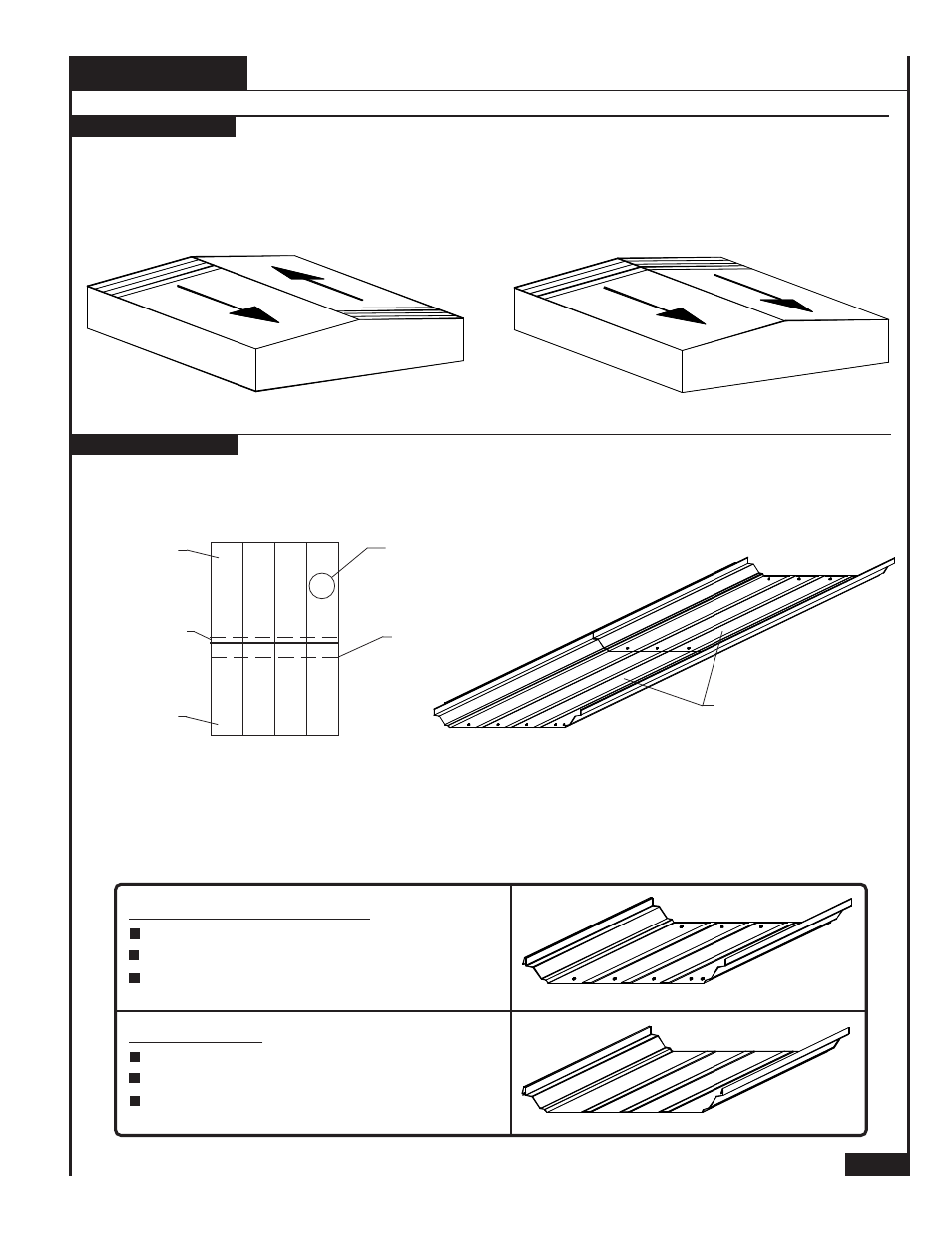

PANEL INSTALLATION

SEQUENCE

EAVE PANEL

PEAK PANEL

7

PEAK

STANDARD PANELS

NOTCHED/PUNCHED

EAVE

PANEL ENDLAP

FACTORY NOTCHED/PUNCHED PANELS - Unless otherwise specified, Metal Sales provides all Snap-

Loc 24 panels with factory rib notching and fastener hole punching on both panel ends. This elimi-

nates reliance on field notching for weathertight seams at panel endlaps and ease of fastener hole

alignment. Panels that are not to be factory notched/punched must be specified at time of order.

OPTIONAL PANEL

Optional if endlapping of panels is not required

No Notching

No Punching

STANDARD PANEL-See page #7

Required when endlapping panels

Used as both the eave and peak panel

Both ends factory notched and punched

PANEL ENDLAPPING

INSTALLATION OPTION #1

INSTALLATION OPTION #2

INSTALLATION DIRECTION

Snap-Loc 24 can be installed on each roof plane from left to right as shown in option #1. Snap-Loc 24

accessories are fabricated to allow the installer to begin work on the left side of the building, continue

across the ridge, and work to the right side of the building, option #2. However, if endlapping of panels

is required, panels must be laid from left to right.