Snap-loc 24 installation of floating rake angle – Metal Sales Snap-Loc 24 Installation User Manual

Page 28

© Metal Sales Manufacturing Corporation / Subject to change without notice. 10/99

27

SNAP-LOC 24

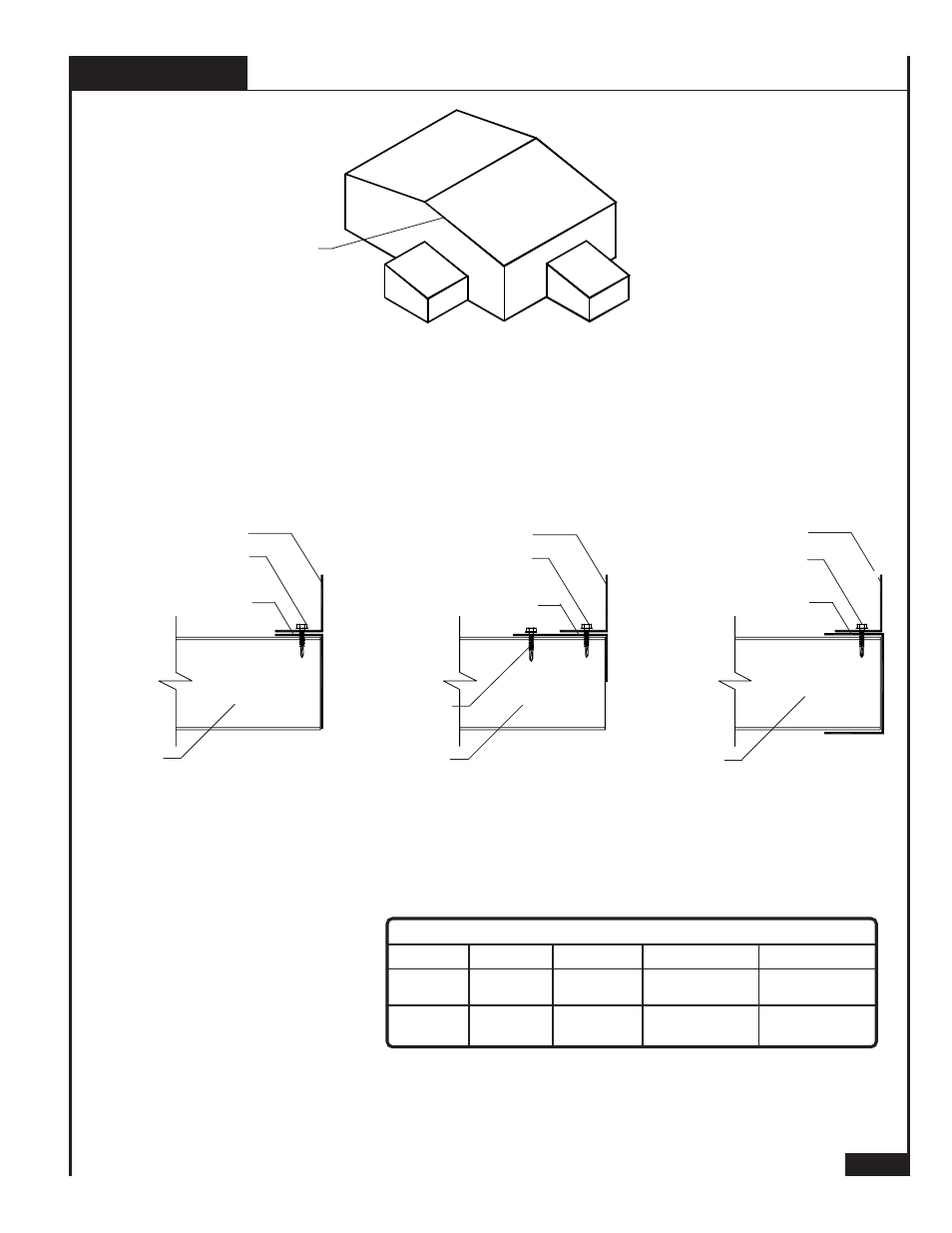

INSTALLATION OF FLOATING RAKE ANGLE

ALTERNATE FLOATING

RAKE ANGLE ATTACHMENT

ALTERNATE FLOATING

RAKE ANGLE ATTACHMENT

PURLIN

FLOATING RAKE ANGLE

RAKE ANGLE

FLOATING RAKE ANGLE

C-CHANNEL

PURLIN

FASTENER

FLOATING RAKE

ANGLE ATTACHMENT

PURLIN

4" TO 6" BLANKET

1"

LOW

HIGH

SYSTEM COMPONENTS

4" TO 6" BLANKET

NONE REQUIRED

3

1

/

4

" LOW

4

1

/

4

" HIGH

3

1

/

8

" LOW

4

1

/

8

" MID

SYSTEM

CLIP

RAKE ANGLE THERMAL BLOCK

INSULATION

RAKE ANGLE

FLOATING RAKE ANGLE

FLOATING RAKE ANGLE

The Floating Rake Angle must be attached to the framing member along the rake. There are

several methods of installing the Floating Rake Angle (see below). Welding of the rake

angle or c-channel to the purlins is recommended so not to obstruct the Floating Rake Angle

attachment.

Refer to the chart for

determination of the proper

Floating Rake Angle. Correct

Floating Rake Angle must be

used for panel system to

function properly.

SHOULDER SELF

DRILLER

SHOULDER SELF

DRILLER

SHOULDER SELF

DRILLER