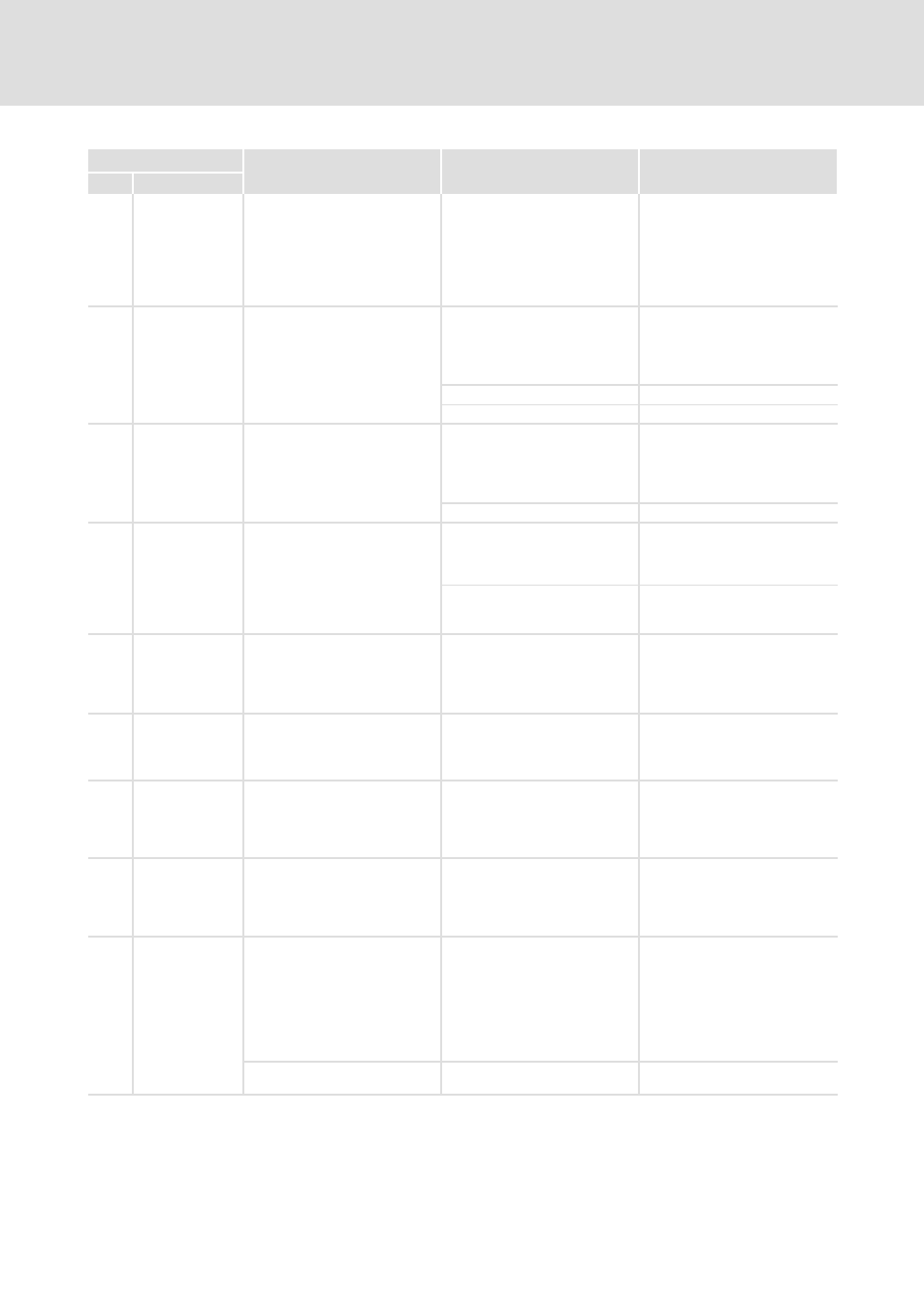

Troubleshooting and fault elimination, Fault messages causes and remedies – Lenze ECSCExxx Power supply module User Manual

Page 123

Troubleshooting and fault elimination

Fault messages

Causes and remedies

l

123

EDBCSXE040 EN 7.0

Remedy

Cause

Description

Fault message

Remedy

Cause

Description

Display

No.

0032

1032

2032

LP1

Mains phase failure

(as of operating system V2.0)

l

No mains phase

l

Mains not sinusoidal

l

Voltage dips ("unstable

mains supply")

l

Check mains voltage

In the case of voltage dips:

l

Reduce charging current

(C0022)

l

For ECS axis modules, set

charge relay function

C0175 = 3.

0050 OH

Heatsink temperature > 90

C

Ambient temperature

T

u

> +40 C or > +50 C

l

Allow power supply module

to cool and ensure better

ventilation

l

Check ambient temperature

in the control cabinet

Heatsink very dirty

Clean heatsink

Incorrect mounting position

Change mounting position

0051 OH1

Internal device temperature

> 90

C

Ambient temperature

T

u

> +40 C or > +50 C

l

Allow power supply module

to cool and ensure better

ventilation

l

Check ambient temperature

in the control cabinet

Incorrect mounting position

Change mounting position

0053 OH3

Overload of external brake

resistor

External brake resistor too hot

by impermissibly high currents

or frequent and too long braking

processes

Check dimensioning

l

No PTC/temperature contact

connected

l

No jumper

Correct wiring

0061 CE0

Communication error on the

automation interface (AIF)

Faulty transfer of control

commands via the automation

interface (AIF).

l

Plug the communication

module/XT keypad firmly

(screw down, if necessary)

l

Switch off monitoring

(C0126 = 3)

0062 CE1

Communication error at the

process data input object

CAN1_IN in cyclic operation

(sync−controlled)

l

CAN1_IN object receives

faulty data

l

Communication is

interrupted

l

Check cable at X4

l

Check transmitter

l

Increase monitoring time

under C0357/1, if necessary

0063 CE2

Communication error at the

process data input object

CAN2_IN in

event−controlled/cyclic

operation without sync

l

CAN2_IN object receives

faulty data

l

Communication is

interrupted

l

Check cable at X4

l

Check transmitter

l

Increase monitoring time in

C0357/2, if necessary

0064 CE3

Communication error at the

process data input object

CAN3_IN in

event−controlled/cyclic

operation without sync

l

CAN3_IN object receives

faulty data

l

Communication is

interrupted

l

Check cable at X4

l

Check transmitter

l

Increase monitoring time in

C0357/3, if necessary

0065 CE4

Bus−off status of the system bus

(CAN)

Power supply module has

received too many faulty

telegrams

l

Check wiring: bus

termination available?

l

Check shield connection of

the cables

l

Check PE connection

l

Check bus load, reduce baud

rate if necessary (observe

cable length)

Toggle bit error

Transmitter does not change

toggle bit

Check transmitter