JLG 340AJ Service Manual User Manual

Page 310

SECTION 6 - JLG CONTROL SYSTEM

6-66

– JLG Lift –

3121259

CHASSIS TILT SENSOR NOT

CALIBRATED

813

The tilt sensor has not been calibrated

The Ground Module reports a

faulted chassis tilt angle of 90

degrees

Calibrate the Tilt sensor to clear

the fault

CHASSIS TILT SENSOR OUT OF

RANGE

814

Fault CHASSIS TILT SENSOR NOT CALIBRATED (813) is not present and

Tilt sensor measurement greater than 19º for 4 seconds. Note: Not to

be reported during Tilt Sensor calibration.

No additional action required

beyond Tilted requirements

specified above. Ground Mod-

ule reports 90

° angle.

Tilt sensor reads less than 19º.

CHASSIS TILT SENSOR DIS-

AGREEMENT

815

The Ground Module detects one of the following conditions:

If a Drive, Steer, or Boom function is active or if the engine is cranking

or if the primary raw Tilt Sensor readings greater than ±10 º then: if

the two ground board tilt sensors disagree by more than or equal to 3

degrees for either the X axis or the Y axis for longer than 5 seconds

then the fault will be logged.

If no Drive, Steer, or Boom functions are active and the engine is not

cranking or the primary raw Tilt Sensor readings are less than ±10 º

then: if the two ground board tilt sensors disagree by more than or

equal to 1 degree for either the X axis or the Y axis for longer than 3

seconds then the fault will be logged.

Note: This fault is not reported if DTC 814 is active.

The Ground Module reports a

faulted chassis tilt angle of 90

degrees

Cycle power to clear the fault.

LSS CELL #1 ERROR

821

MACHINE SETUP

LOAD SYSTEM is not set = NO

The Ground Module detects that LSS is reporting error with Cell #1

Ground Module to assume Plat-

form Load State = Overloaded

CAN messages are received

from the LSS module.

LSS CELL #2 ERROR

822

MACHINE SETUP

LOAD SYSTEM is not set = NO

The Ground Module detects that LSS is reporting error with Cell #2

Ground Module to assume Plat-

form Load State = Overloaded

CAN messages are received

from the LSS module.

LSS CELL #3 ERROR

823

MACHINE SETUP

LOAD SYSTEM is not set = NO

The Ground Module detects that LSS is reporting error with Cell #3

Ground Module to assume Plat-

form Load State = Overloaded

CAN messages are received

from the LSS module.

LSS CELL #4 ERROR

824

MACHINE SETUP

LOAD SYSTEM is not set = NO

The Ground Module detects that LSS is reporting error with Cell #4.

Ground Module to assume Plat-

form Load State = Overloaded

CAN messages are received

from the LSS module.

LSS HAS NOT BEEN CALI-

BRATED

825

MACHINE SETUP

LOAD SYSTEM is not set = NO

The load sensor has not been calibrated

Ground Module to assume Plat-

form Load State = Overloaded

CAN messages are received

from the LSS module.

RUNNING AT CREEP – PLAT-

FORM OVERLOADED

826

Machine Setup

LOAD SYSTEM = WARN ONLY

The platform is Overloaded

Ground mode is active with Emergency Descent mode not active or

Platform mode is active

Refer to Table 6-11, Overload

Variations for machine

response.

Not all of the trigger conditions

are met

DRIVE & BOOM PREVENTED –

PLATFORM OVERLOADED

827

The Platform is Overloaded and

Machine Setup

LOAD SYSTEM = CUTOUT PLATFORM, Platform

Mode is active, and conditions of Table 6-11, Overload Variations

apply.

-or-

The Platform is Overloaded and Machine Setup

LOAD SYSTEM =

CUTOUT ALL and conditions of Table 6-11, Overload Variations apply.

Refer to Table 6-11, Overload

Variations for machine

response.

Not all of the trigger conditions

are met

LIFT UP & TELE OUT PRE-

VENTED – PLATFORM OVER-

LOADED

828

MACHINE SETUP

LOAD SYSTEM = SPECIAL 1

Platform Mode is active

The platform is Overloaded

Refer to Table 6-11, Overload

Variations for machine

response.

Not all of the trigger conditions

are met

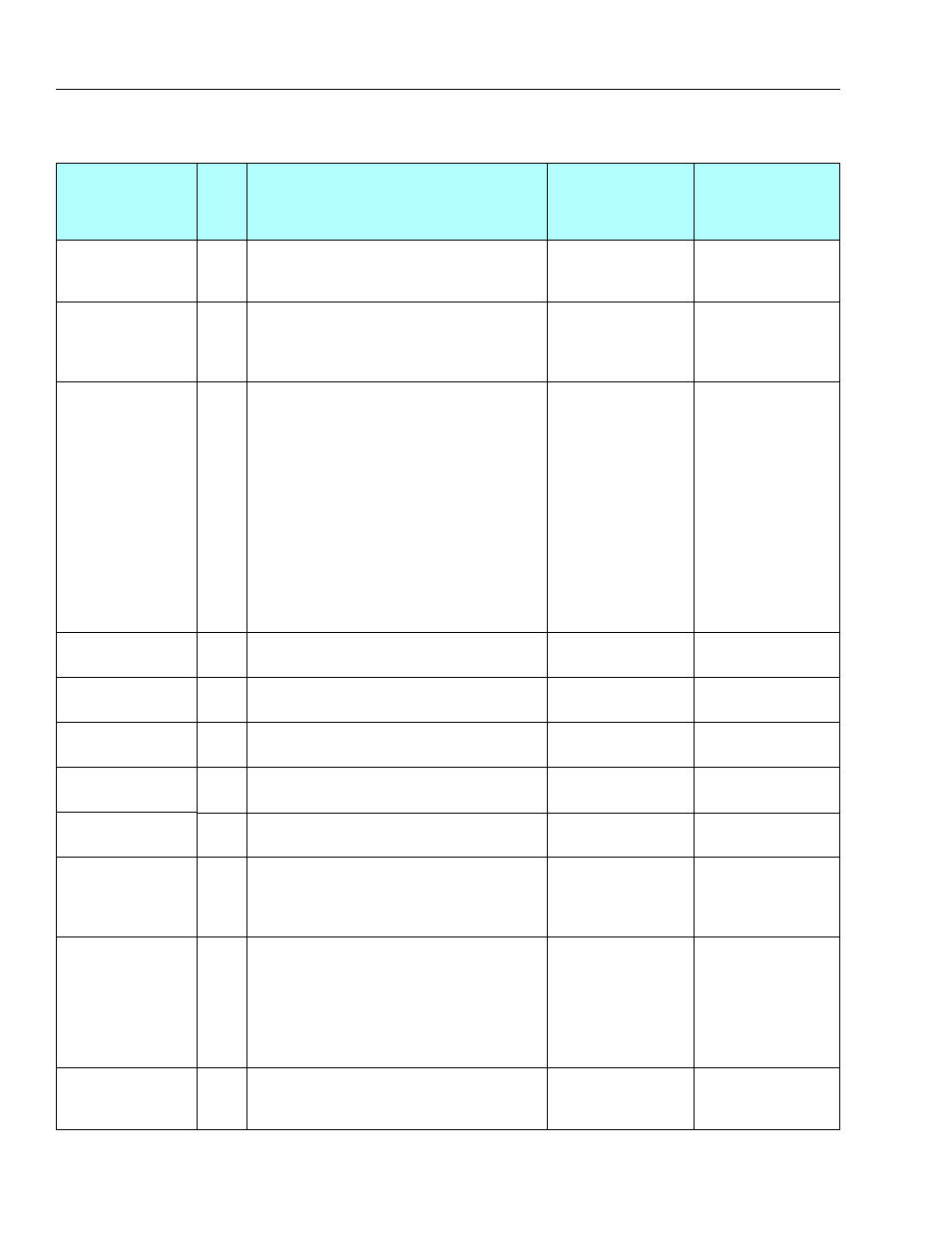

Table 6-10. Fault Code Troubleshooting Information

Help Message

DTC

Condition Producing DTC

Control System Response or

Machine Condition

Corrective Action/

Operational Requirement

for Function Movement

and/or to Clear Fault