Displacement limiter adjustment data -54 – JLG 340AJ Service Manual User Manual

Page 212

SECTION 5 - HYDRAULICS

5-54

– JLG Lift –

3121259

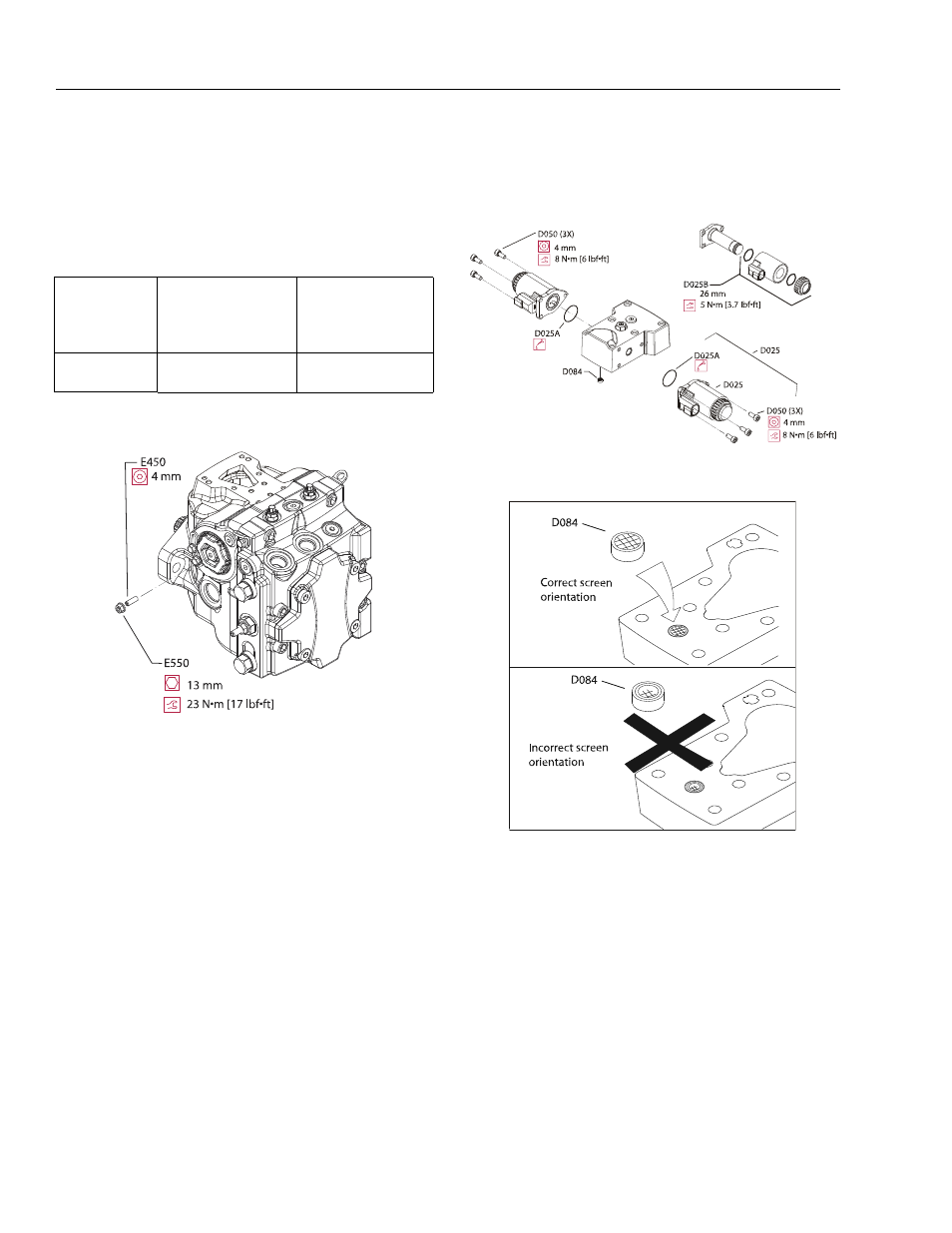

OPTIONAL DISPLACEMENT LIMITER INSTALLATION

NOTE:

Set the approximate displacement limiter depth. See the

table below for displacement change per turn. Run screw

in until it contacts the servo piston, then back out the

appropriate number of turns.

1.

Thread displacement limiter adjusting screw (E450) into

servo sleeve.

2.

Thread a new locking nut onto adjustment screw.Torque

to 23 Nm [17 ft.lbs.] using a 13mm hex wrench.

EDC CONTROL ASSEMBLY

1.

Install new O-rings (D025A) into solenoids (D025), and

attach solenoids with capscrews (D050) using 4 mm

internal hex wrench. Torque to 8 Nm [6 ft.lbs.].

2.

Replace screen (D084) if removed. Drawing shows

proper screen orientation.

NOTE:

If you suspect coil malfunction, remove the coil (D025B) by

removing the plastic nut with a 26 mm 12 point socket.

Install a new coil and torque the nut to 5 Nm [3.7 ft.lbs.].

Table 5-6. Displacement limiter adjustment data

Locknut wrench

size and torque

Adjusting screw size

Approximate

displacement change per

revolution of adjusting

screw

13 mm 23 Nm

[17 ft.lbs.]

4 mm internal hex

5.1 cm

3

[0.31 in

3

]