Disassembly procedure, Disassembly procedure -6, Special tools -6 – JLG 340AJ Service Manual User Manual

Page 164

SECTION 5 - HYDRAULICS

5-6

– JLG Lift –

3121259

Disassembly Procedure

1.

Remove the oil from the cylinder.

2.

Fix the cylinder in a vertical or horizontal position. Verti-

cal position is convenient for disassembly and assembly.

Fix the base by inserting the pin not to be rotated.

Remove any hoses, valves, or fittings that may be in the

way.

3.

Unscrew the cylinder Head

Glands that are threaded into the barrel are locked in

place with caulking. Using a spanner wrench, unscrew

the gland from the barrel. (It is easier to do this with rod

pulled out 5cm from the gland). If there is no caulking,

continue with the disassembly process.

4.

Remove the Rod assembly

a. Check if the cap or plug has been removed from the

cylinder ports.

b. Place a suitable container under the cylinder to

catch any oil coming out of the cylinder.

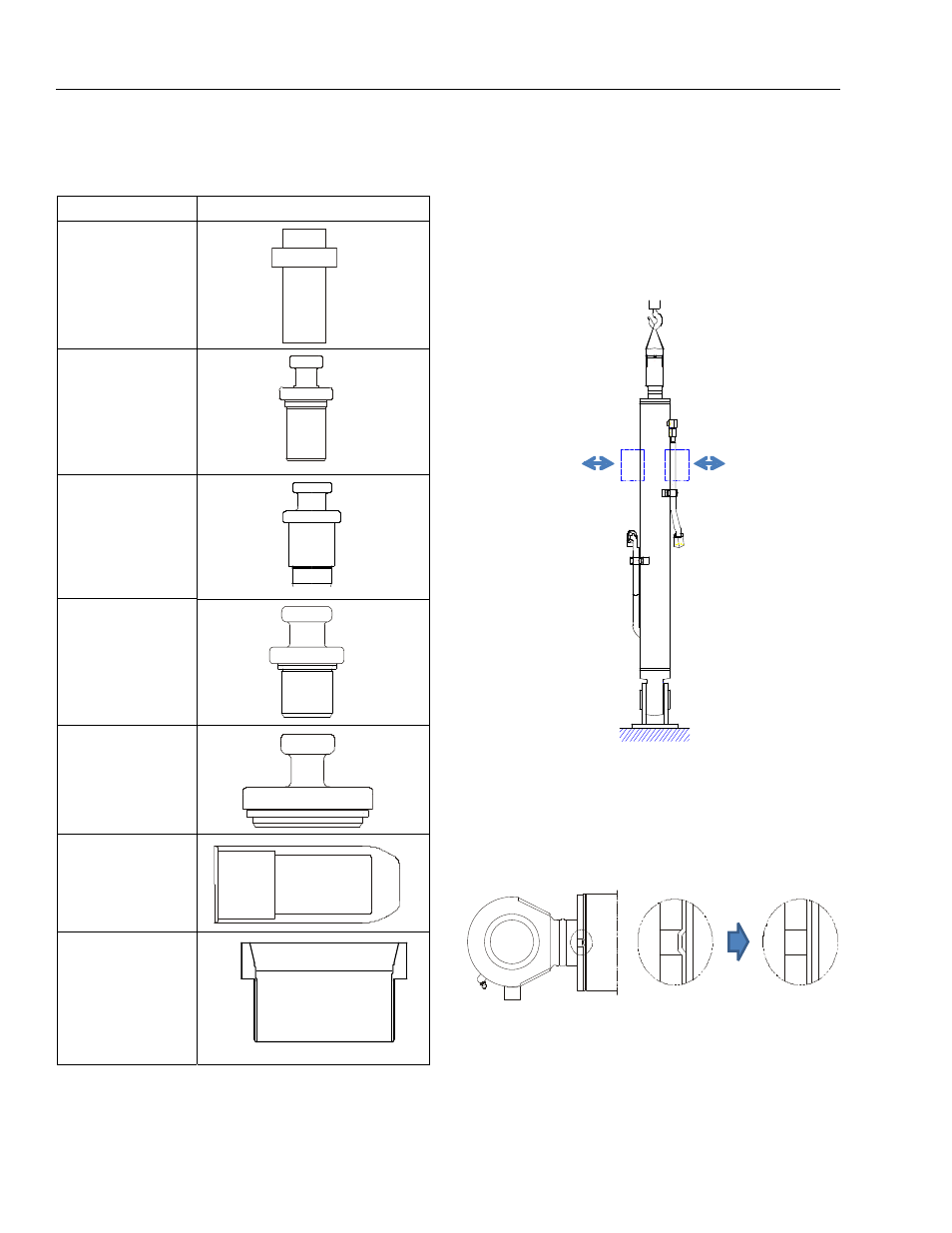

Table 5-3. Special Tools

Name of Tool

Description

Bushing for Disassembly

Bushing for Press

MRP Bearing Disassembly

MRP Bearing Press

Dust Wiper Press/

Dust Wiper Insert

Gland Seal Protection

(Gland Guide Jig)

Piston Seal Protection

(Piston Guide Jig)