JLG 340AJ Service Manual User Manual

Page 203

SECTION 5 - HYDRAULICS

3121259

– JLG Lift –

5-45

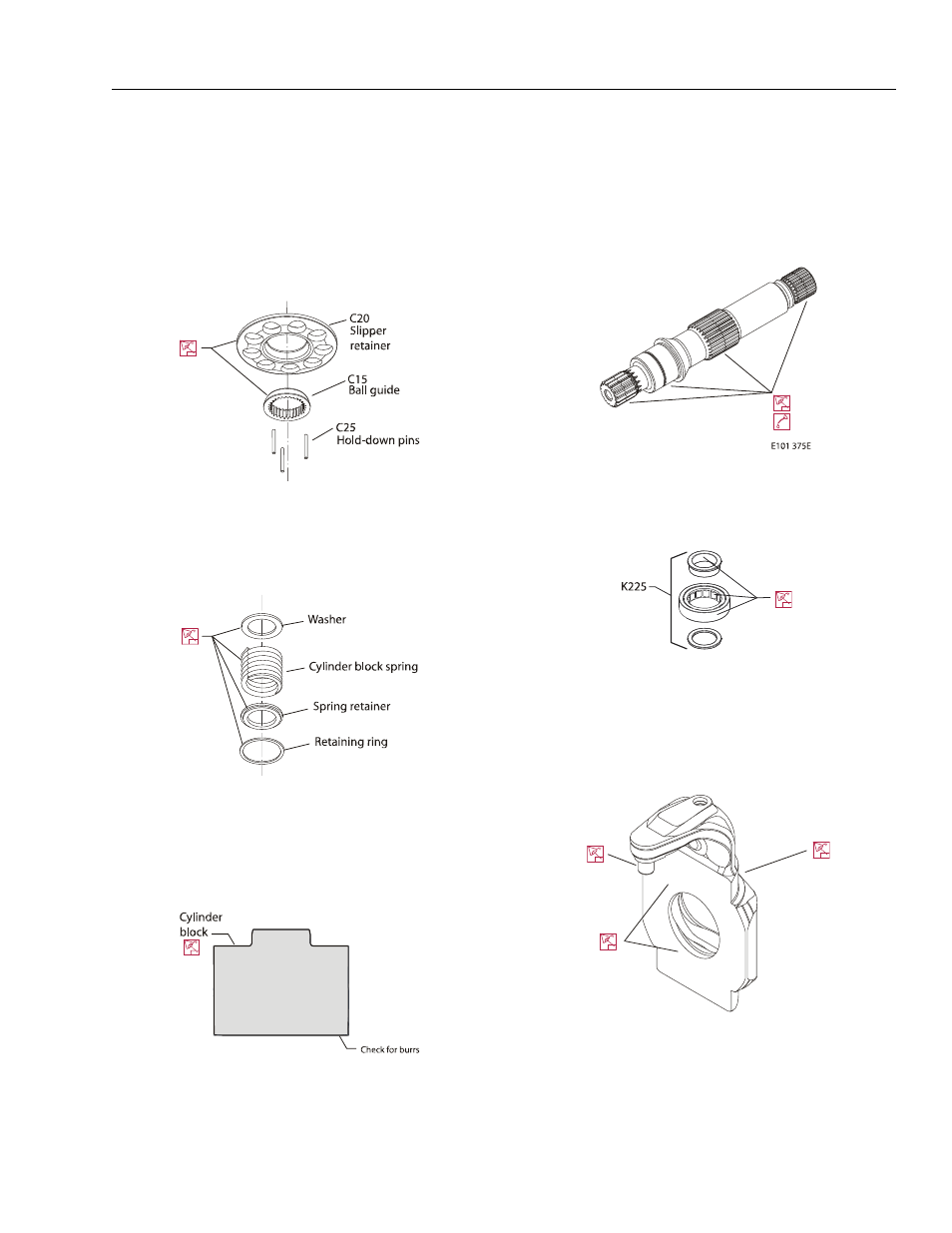

BALL GUIDE, SLIPPER RETAINER, AND HOLD-DOWN

PINS

Ensure ball guide is free of nicks and scratches, and not scored.

Examine for discoloration that may indicate excessive heat or

lack of lubrication.The slipper retainer should be flat, and slip-

pers should fit in the retainer with minimal side play. Place the

hold-down pins on a flat surface and roll them to make sure

they are straight. Discard and replace any damaged parts.

BLOCK SPRING, AND WASHERS

If cylinder kit was fully disassembled, visual inspection of the

cylinder block, spring, and washers should indicate minimal

wear. Replace if cracks or other damage are present.

CYLINDER BLOCK

Examine the running face of the cylinder block. The surface

should be smooth and free of nicks and burrs. Ensure that no

scratches or grooves exist; these may drastically reduce output

flow.

SHAFT

Check to see that the shaft and its splines are straight and free

of damage or heavy wear. Inspect the shaft surface where it

meets the shaft seal. Replace the shaft if a groove exists at the

sealing land surface where it meets the shaft seal. Clean the

sealing area with a nonabrasive material if necessary. Lubricate

the shaft with a light coat of hydraulic fluid before reassembly.

SHAFT BEARING

Clean bearing with a solvent and lubricate with hydraulic fluid.

Inspect for wear, or pitting. Rotate the bearing in your hand.

Replace if it does not rotate smoothly.

SWASHPLATE

Carefully inspect each machined surface of the swashplate for

wear. Ensure all swashplate surfaces are smooth. Inspect the

swashplate's slipper running surface for flatness and brass

transfer. Excessive brass transfer from slippers may indicate

you should replace the slippers. Check the journals for

scratches. Replace swashplate if necessary.

VALVE PLATE

Inspect the valve plate for scratches and grooves. Check the

plate for pitting along the running face. If pitting from cavita-

tion exists, replace the valve plate. Check for excess wear on

the brass running face. If you observe any discoloration or

burn marks, replace the valve plate.