JLG 340AJ Service Manual User Manual

Page 208

SECTION 5 - HYDRAULICS

5-50

– JLG Lift –

3121259

NOTE:

After pump assembly is complete, mount pump on test

stand. Perform mechanical neutral adjustment and control

neutral adjustment. Refer to HI Closed Circuit Axial Piston

Pumps 078/147/165 Service Manual 520L0848 for adjust-

ment procedures.

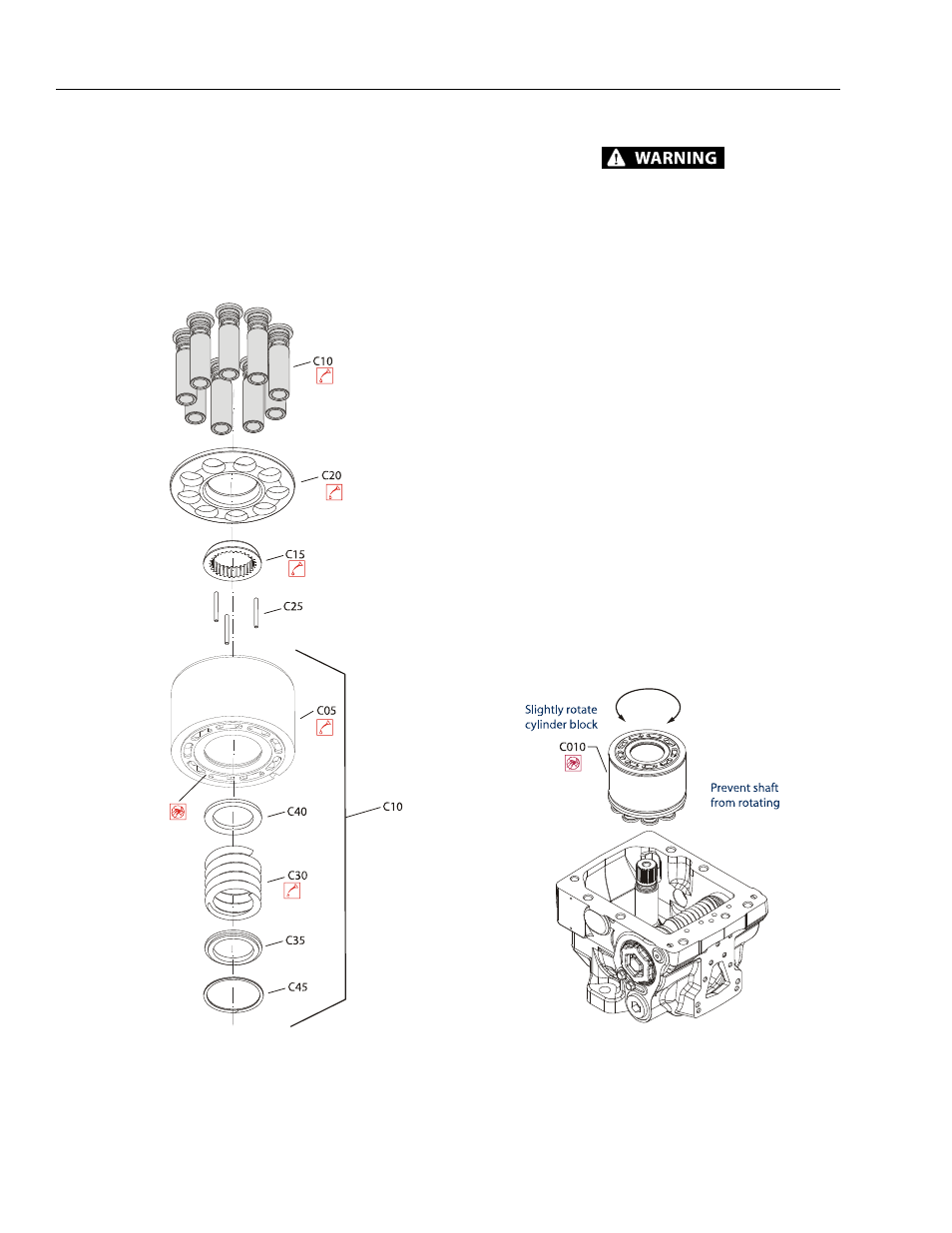

CYLINDER KIT REASSEMBLY

1.

Coat all parts with hydraulic fluid prior to reassembly.

2.

Install the inner block spring washer (C40), block spring

(C30), and outer washer (C35) into the cylinder block.

Using a press, compress the block spring enough to

expose the retaining ring groove. Wind the spiral retain-

ing ring (C45) into the groove in the cylinder block.

RISK OF PERSONAL INJURY: COMPRESSING THE BLOCK SPRING REQUIRES

ABOUT 350 TO 400 N [80 TO 90 LB.F.]. USE A PRESS SUFFICIENT TO MAINTAIN

THIS FORCE WITH REASONABLE EFFORT. ENSURE THE SPRING IS SECURE

BEFORE ATTEMPTING TO INSTALL THE SPIRAL RETAINING RING. RELEASE THE

PRESSURE SLOWLY AFTER THE RETAINING RING IS INSTALLED.

3.

Turn the block over and install the hold-down pins (C25)

and ball guide (C15) into the cylinder block.

4.

Insert the pistons (C10) into the slipper retainer (C20).

Install the piston/retainer assembly into the cylinder

block. Ensure the concave surface of the retainer seats

on the ball guide. If you are reusing the pistons, install

them to the original block bores. Lubricate the pistons,

slippers, retainer, and ball guide before assembly. Set

the cylinder kit aside on a clean surface until needed.

NOTE:

Be sure to install the slipper retainer (C20) so it mates cor-

rectly with the ball guide (C15) (concave side of the slipper

retainer against the convex side of the ball guide).

CYLINDER KIT INSTALLATION

1.

Position pump with shaft pointing down.

2.

Insert the cylinder block kit onto the shaft. While hold-

ing the shaft, slightly rotate the cylinder block kit to help

start the shaft splines over the ball guide and align it

with the block splines.