Troubleshooting, Troubleshooting -84 – JLG 340AJ Service Manual User Manual

Page 242

SECTION 5 - HYDRAULICS

5-84

– JLG Lift –

3121259

Troubleshooting

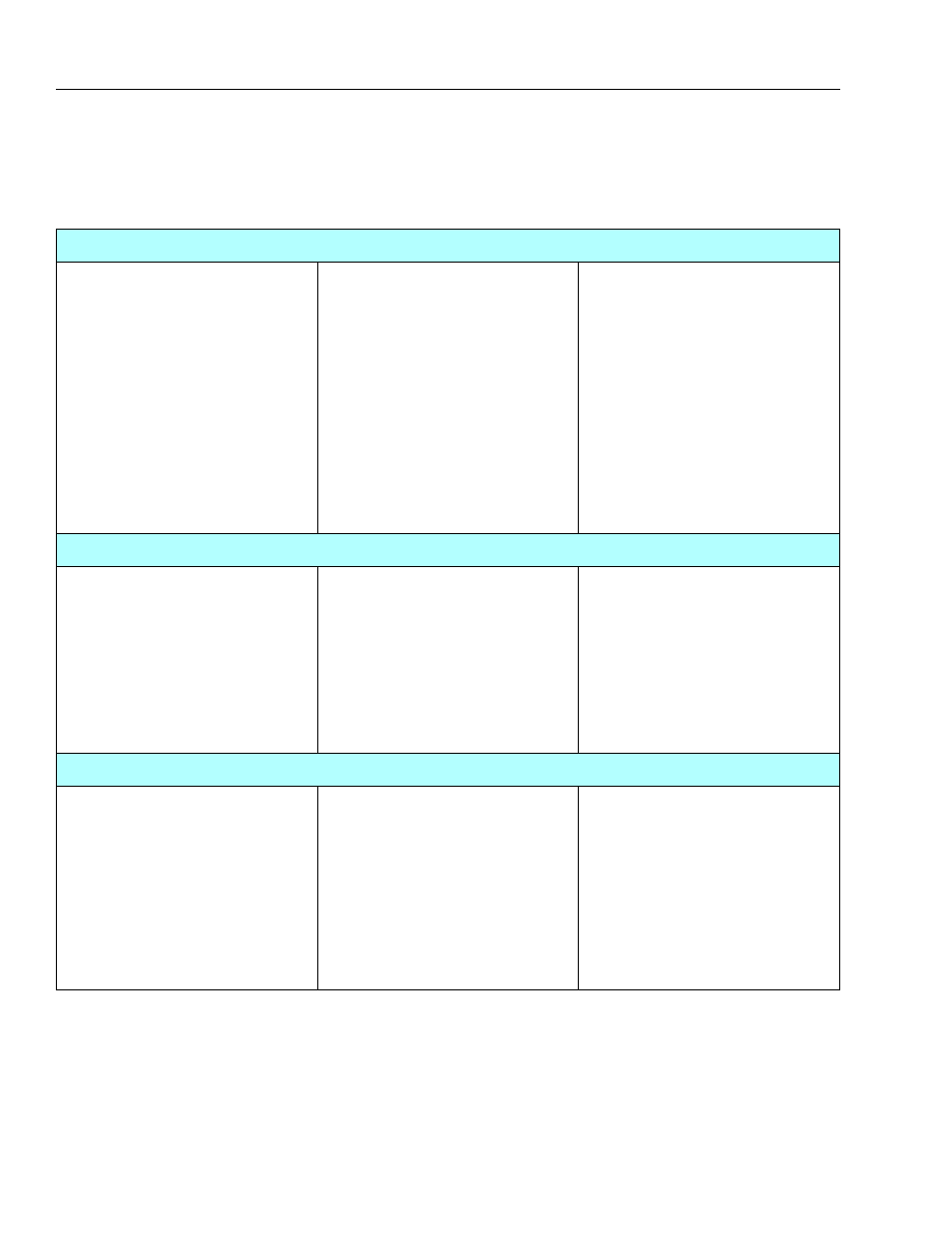

Table 5-17. Troubleshooting

Low or No Flow From Gear Pump

Item

1.

Check oil level in reservoir.

2.

Check input spline condition.

3.

Check pressure at pump inlet. Recommended inlet

pressure: 0.8 to 3.0 bar absolute. 0.6 Minimum at

cold start.

4.

Check condition of gear faces and bearing blocks.

5.

Check bushings.

Description

Insufficient oil to supply gear pump.

Input shaft broken or stripped.

Clogged suction filter or inlet screen.

Scored bearing block and gear faces will reduce pump effi-

ciency.

Overpressure of gear pump will cause idler gear bushing to

fail.

Action

Fill reservoir to proper level.

Repair or replace gear pump.

Replace filter or clean suction screen.

Repair or replace gear pump.

Repair or replace gear pump.

Excessive Noise

Item

1.

Check oil level in reservoir.

2.

Check inlet line for leaks.

3.

Check pressure at pump inlet.

Recommended inlet pressure: 0.8 to 3.0 bar absolute. 0.6

Minimum at cold start.

Description

Excessive air will cause cavitation sound.

Excessive air will cause cavitation sound.

Lower than normal inlet pressure causes excessive pump

noise.

Action

Fill reservoir to proper level.

Repair inlet line.

Return inlet pressure to recommended levels.

External Leakage

Item

1.

Check for pinched o-rings or backup ring seal.

2.

Check pressure seals.

Description

Pinched seal will allow leakage.

Damage to pressure seals is typically caused by reduced

"stack-up" in the pump assembly. This may be due to

under-torqued assembly fasteners, or more commonly is

attributed to excessive wear on the bearing blocks.

Reduced "stack-up" will affect seal efficiency possibly to

the point of seal extrusion.

Action

Replace pinched seal.

Inspect condition of bearing blocks. If they are found to be

worn, repair or replace the pump.

If bearing blocks are not worn, replace pressure seals and

re-torque pump assembly fasteners.