Pressure limiter valve replacement, 4 gear pump, Disassembly – JLG 340AJ Service Manual User Manual

Page 232: Pressure limiter valve replacement -74, Gear pump -74, Disassembly -74, 4 gear pump disassembly

SECTION 5 - HYDRAULICS

5-74

– JLG Lift –

3121259

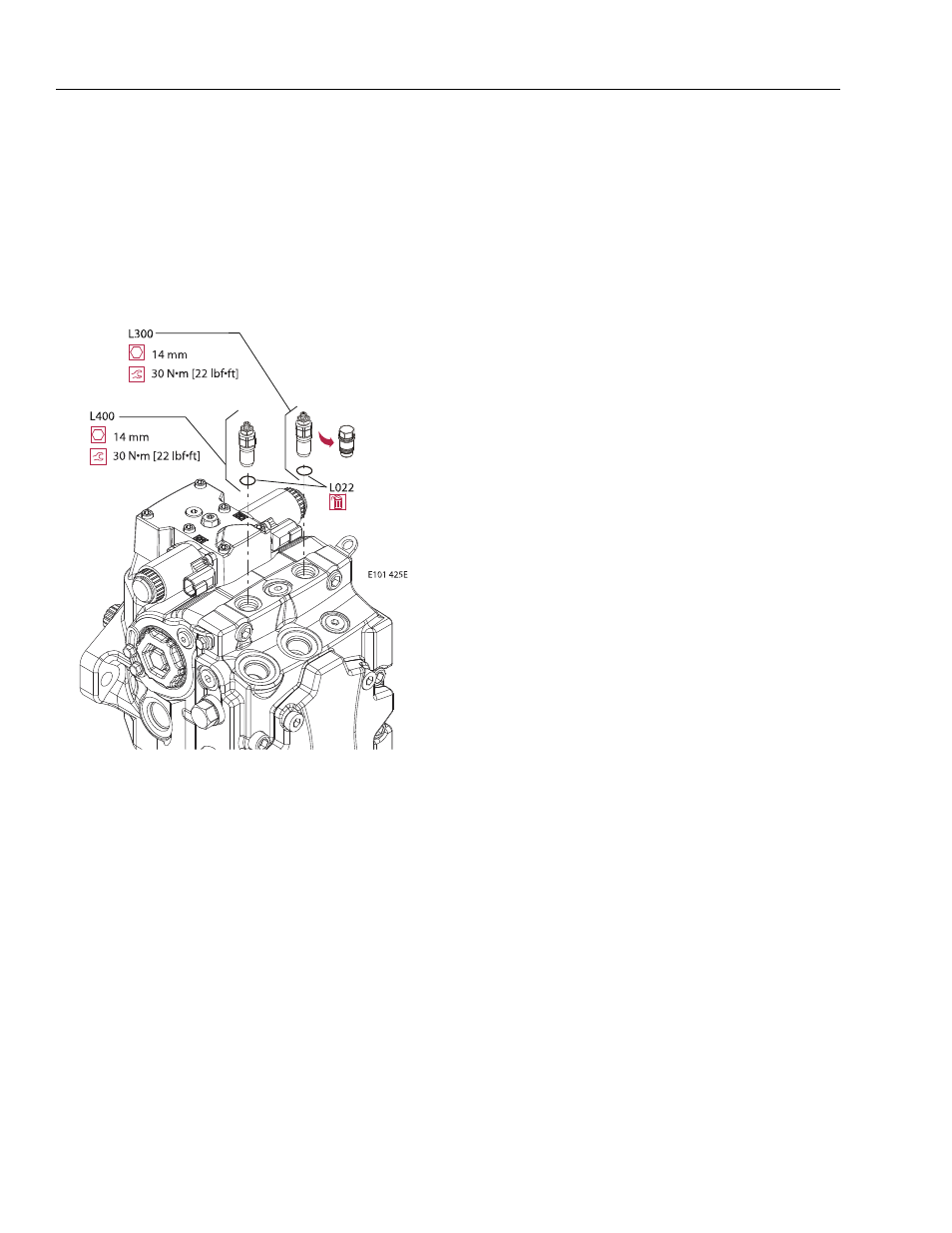

Pressure Limiter

Valve Replacement

Replace the pressure limiter valve as a complete unit. Do not

attempt to repair individual components. See Pressure limiter

adjustment for adjustment instructions.

REMOVAL, INSPECTION, ASSEMBLY

1.

Using a 14 mm wrench, remove the pressure limiter

valve (L100). Discard O-ring.

2.

Inspect the sealing surfaces of the pump for nicks or

scratches.

3.

Install new O-ring. Lubricate O-ring with petroleum jelly.

4.

Replace pressure limiter valve. Torque to 30 Nm [22

lb.ft.].

5.

Operate pump at full range of controls to ensure proper

machine operation. Pressure limiter is available as com-

plete unit only. O-ring is available separately.

5.4

GEAR PUMP

Disassembly

Prior to proceeding with disassembly, it may be necessary to

prepare some subassemblies separately.

The details for preparing each subassembly are given in the

following section.

Also, some general recommendations are given below.

CLEANLINESS

Cleanliness is a primary factor for reliable pump performance.

Wash the outside of the pump thoroughly before disassembly

and all pieces prior to assembly. Cleaning parts with clean

shop solvent and air drying is usually adequate.

LUBRICATION OF MOVING PARTS

During assembly, it is imperative to provide lubrication with

clean hydraulic oil to all the running parts of the pump.

It is also necessary to coat the seals with grease. The absence

of lubrication during assembly can cause the unit to seize after

a few minutes of running.

CARE OF SURFACE TREATMENT

Be careful when handling all the internal surfaces, especially

bearings, gears, and body faces. Do not touch or score them

with metal tools or cutting edges.