Hydraulic oil, Major component weights, Hydraulic oil -2 major component weights -2 – JLG 340AJ Service Manual User Manual

Page 18: Gm 0.97l -2, Hydraulic oil -2, Critical stability weights -2

SECTION 1 - SPECIFICATIONS

1-2

– JLG Lift –

3121259

Hydraulic Oil

NOTE:

Hydraulic oils require anti-wear qualities at least API Ser-

vice Classification GL-3, and sufficient chemical stability

for mobile hydraulic system service.

NOTE:

Machines may be equipped with Mobil EAL biodegrad-

able and non-toxic hydraulic oil. This is a fully synthetic

hydraulic oil that possesses the same anti-wear and rust

protection characteristics as mineral oils, but will not

adversely affect the ground water or the environment

when spilled or leaked in small amounts.

NOTE:

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not con-

tain the same required additives or be of comparable vis-

cosities. If use of hydraulic oil other than Mobil 424 is

desired, contact JLG Industries for proper recommenda-

tions.

Major Component Weights

DO NOT REPLACE ITEMS CRITICAL TO STABILITY WITH ITEMS OF DIFFERENT

WEIGHT OR SPECIFICATION (FOR EXAMPLE: BATTERIES, FILLED TIRES, PLAT-

FORM) DO NOT MODIFY UNIT IN ANY WAY TO AFFECT STABILITY.

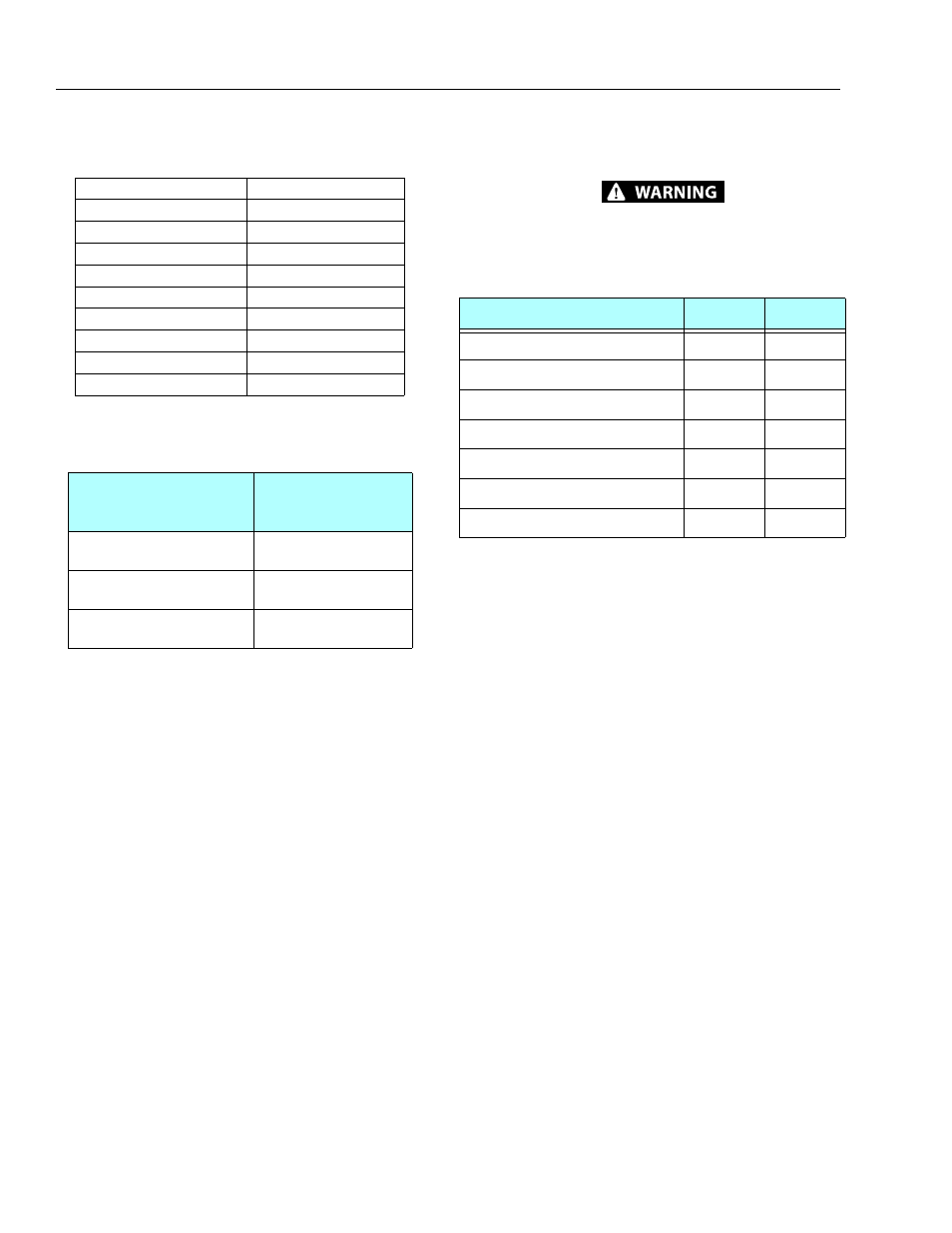

Table 1-6. GM 0.97L

Type

Liquid Cooled

Number of Cylinders

4

Bore

2.58 in. (65.5 mm)

Stroke

2.84 in. (72.0 mm)

Total Displacement

59 cu. in. (967 cm3)

Compression Ratio

8.8:1

Firing Order

1-3-4-2

Output

28.6 hp (21.3 kW)

Low Idle RPM

1200 ± 50

High Idle RPM

3000± 50

Table 1-7. Hydraulic Oil

Hydraulic System

Operating

Temperature Range

S.A.E. Viscosity

Grade

+0° to + 180° F

(-18° to +83° C)

10W

+0° to + 210° F

(-18° to +99° C)

10W-20, 10W30

+50° to + 210° F

(+10° to +99° C

20W-20

Table 1-8. Critical Stability Weights

Components

LBS.

KG.

Counterweight

1875 ± 75

850.5 ± 34

Tire and Wheel - 20x9 Pneumatic

130

59

Tire and Wheel - 20x9 Foam-Filled

220

99.8

Tire and Wheel - 18x7

230

104.3

Platform & Console - 30x60

242.5

110

Platform & Console - 30x48

216

98

Battery

66

30