Burnham Series 5B User Manual

Page 69

69

If Burners must be removed, use the following

procedure:

a. Mark location on manifold of all burners with pilots.

b. Using a pair of pliers, remove hitch pin clips

(shaped like a hairpin) from groove in main burner

orifices. SAVE ALL CLIPS.

c. Remove all burners without pilots by lifting front

of burner slightly, then pushing burner toward rear

of boiler until front of burner clears orifice, then

lift rear of burner until head of weld pin on bottom

rear of burner clears keyhole slot in base rear

panel. Burner is now free and can be lifted out thru

opening in base front frame.

d. Remove all burners with pilots by first tracing all

electrical leads coming from pilot to their points of

connection, remove leads from terminals to which

they are connected, and then tag each lead with

respective terminal designation. Disconnect Pilot

Tubing at nearest connection to pilot and remove

burner as outlined in paragraph c. above.

e. When replacing burners, reverse procedure used in

removal of burners. Make sure burners are secure in

keyhole slots in base rear panel and hitch pin clips

are installed in grooves in all main burner orifices.

Burners with pilots must be in same locations as

original installation. If markings placed on manifold

(when burners were removed) are obliterated, see

Fig. 58. Reconnect electrical leads and reconnect

pilot tubing.

Reinstall Flue Cleanout Plates so that they are gas

tight. Reinstall Burner Access Panels and Jacket

Panels.

4.

LUBRICATION

Manufacturers Instruction should be followed on all

parts installed on the boiler that require lubrication.

Generally this involves only the circulator in a hot

water system. This includes:

(a) Type of lubricant to be used

(b) Frequency of lubrication

(c) Points to lubricate

5.

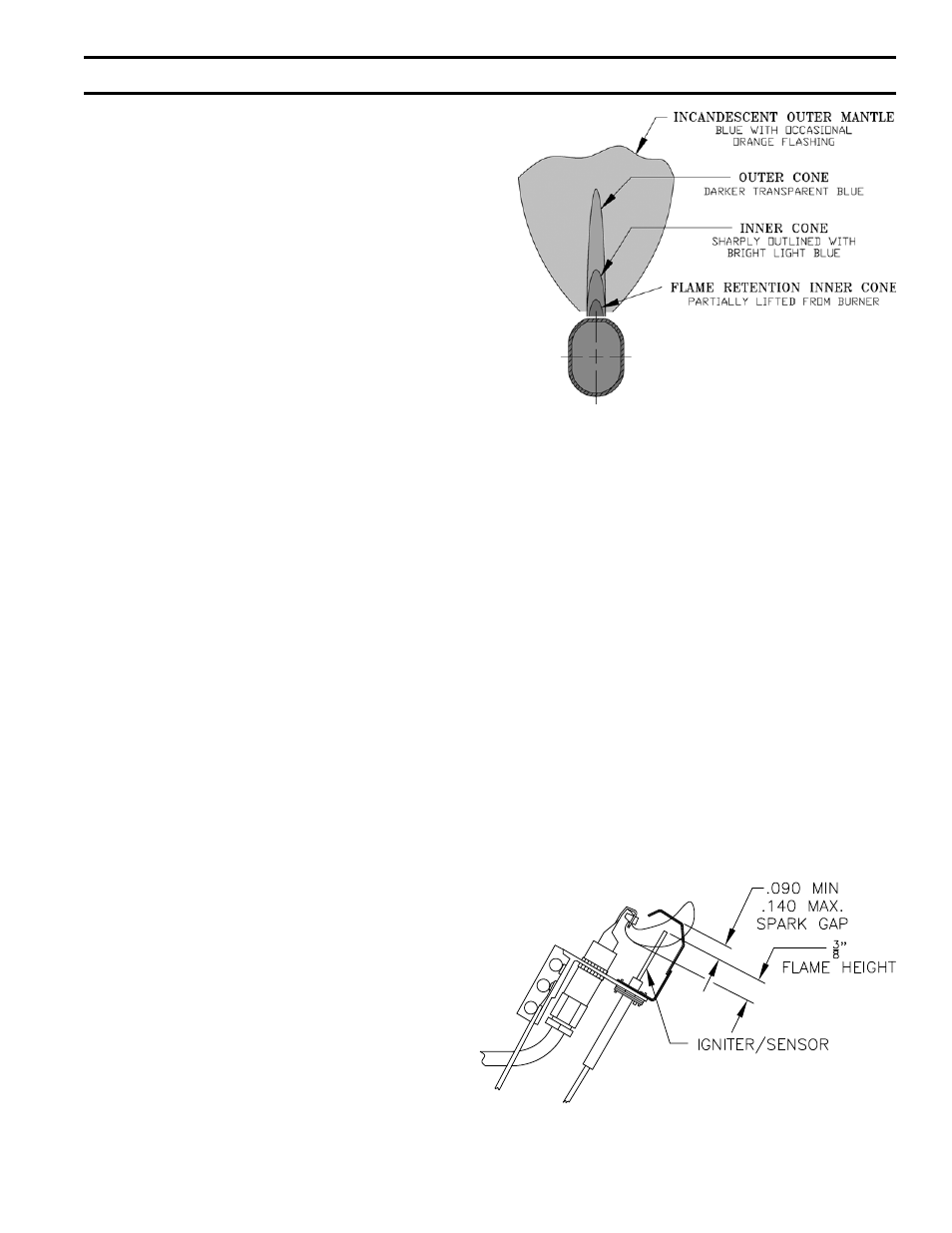

MAIN BURNER FLAMES –

Main Burner Flames should be checked at initial

start-up, annually thereafter, or after flueway cleaning,

or after an extended shutdown period. Main Burner

Flame should have a clearly defined inner cone, see

Fig. 59, with no yellow tipping. Orange-yellow streaks

caused by dust should not be confused with true yellow

tipping.

Yellow-tipping indicates a lack of primary air and

normally can be corrected by opening the air shutter.

Improper alignment of burner on orifice will also affect

primary air injection.

SECTION V – SERVICE (continued)

FIG. 59

MAIN BURNER FLAME ADJUSTMENT

FIG. 60

PILOT FLAME - HONEYWELL Q3481B

6.

PILOT FLAME –

Pilot Flame should be checked at initial start-up,

annually thereafter, or after flueway cleaning, or after

an extended shutdown period.

The EI Control System utilizes a Honeywell Q3481B

pilot. Flame should be adjusted by means of the pilot

line regulator 5.5” WC pilot line press so that a medium

hard center flame envelopes approximately 3/8” of

the end of the sensing probe, see Fig. 60. If flame

is yellow, primary air slot may be covered with dirt

or lint. This can be removed with a soft brush or by

vacuuming.

a. To adjust or check spark gap between electrode and

hood on Honeywell Q3481B intermittent pilot. (See

Fig. 60)

1. Use a round wire gauge to check spark gap.

2. Spark gap should be 0.1” for optimum

performance.

The OP Control Systems utilize a Honeywell

Q179D Flame Rectification Pilot to which a Q309

thermocouple has been added. Adjust pilot line