Burnham Series 5B User Manual

Page 11

11

c. Insert short end of draw-up rod through front & rear

nipple ports on both sections, see Fig. 5.

d. Place two (2) flat washers, draw-up channel and a

nut on each end of draw-up rods and finger tighten.

e. DRAW UP CENTER SECTION SLOWLY AND

EVENLY, tightening each DRAW-UP ROD a little

at a time so that sections are equally spaced. KEEP

NIPPLES ALIGNED WITH NIPPLE PORTS. If

necessary, tap Nipples lightly with a blunt tool or

rod to keep Nipples from cocking while Sections are

being drawn up. DO NOT DRAW UP SECTION(S)

WHEN NIPPLES ARE COCKED. Continue

tightening Draw-Up Rods equally until Sections

meet iron-to-iron on the ground surface. BUMPING

OUTER EDGES OF SECTION WITH WOODEN

BLOCK WILL EASE DRAW-UP OPERATION.

f. KEEP DRAW-UP ROD THREADS, NUTS AND

WASHERS LUBRICATED with grease or heavy oil

to prevent damage to rods and threads and to make

assembling easier.

g. USING A PINCH BAR, insert WOOD WEDGES

under last Center Section assembled so as to raise

it just above Boiler Base. This will keep the next

section to be assembled above the base, thus making

it easier to join and draw-up. MOVE WOOD

WEDGES FORWARD EACH time a Section has

been drawn up.

7.

ASSEMBLE REMAINING END SECTION WITH

DRAW-UP RODS in a manner similar to that for

assembling Center Sections. Remove wedges from

under Boiler. Be sure Boiler is aligned and seated on

Base.

a. After section assembly is completed install 5/8” tie

rods from tie rod bundle through the upper lug holes

in the front of Boiler and Lower lug holes in the rear

of Boiler sections and tighten until they are finger

tight only, to allow for expansion. This is necessary

in order to allow clearance for installation of Flue

cover plates. Finally, remove ¾” draw-up rods from

nipple ports.

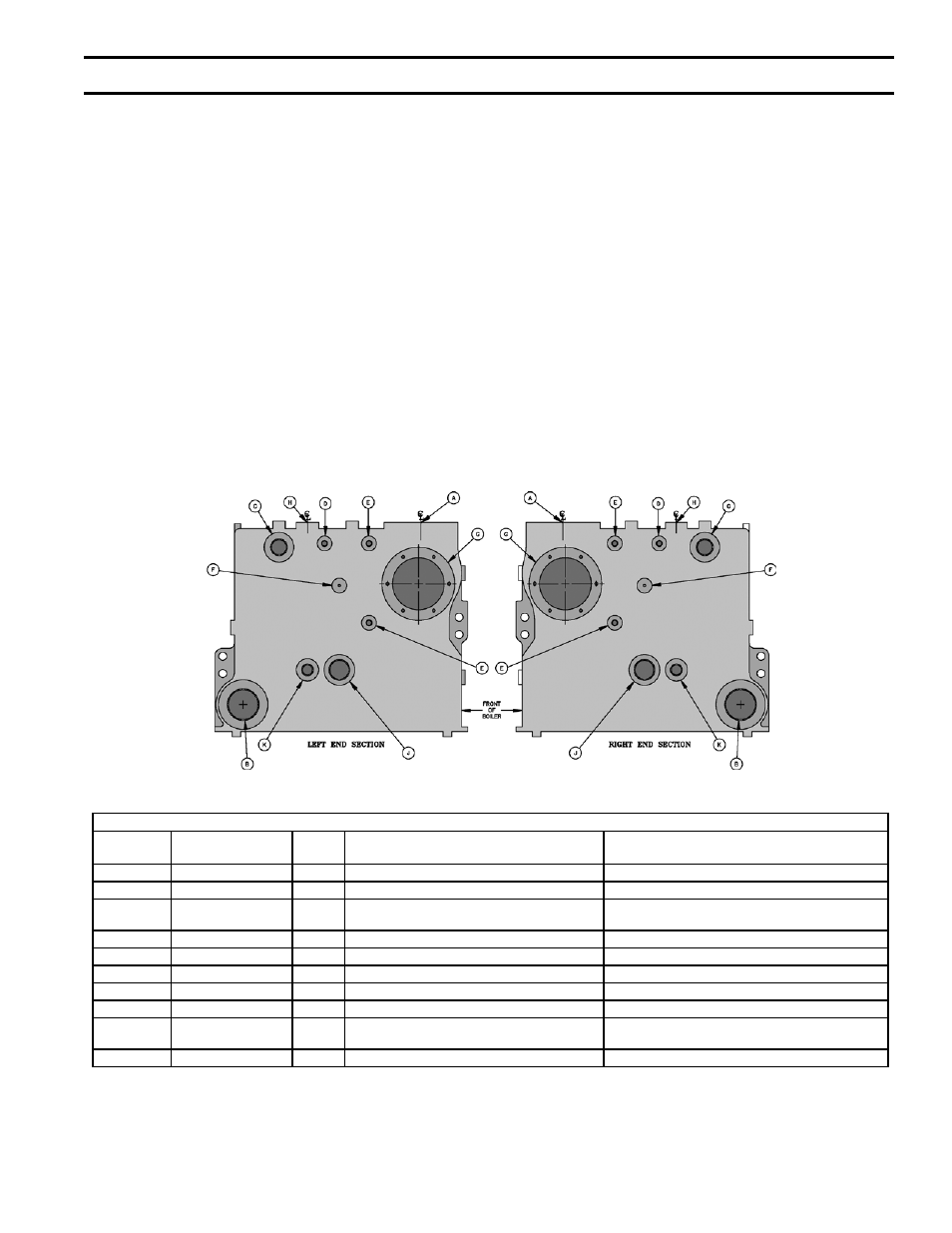

FIG. 7

PURPOSE OF TAPPINGS AND THEIR LOCATIONS

PURPOSE OF TAPPINGS

1

Location

Tapping Per

End Section

Size

Steam Boilers

Water Boilers

A

1

3”

Supply

Supply

B

1

3”

Return

Return

C

2

1

1-1/2”

Pressure Operating Control

(Bushed to 1/4”)

Temperature Operating Control (less heater)

Bushed to 3/4”; Plug (with heater)

D

1

1/2”

Pressure Gauge

Theraltimeter

E

2

1/2”

Water Gauge, LWCO & Pressure Limit

Plug

F

1

3/8”

Try-Cock (Special Order)

----

G

3

1

----

Cover Plate

Cover Plate or Tankless Heater

H

1

1”

See Note 4

See Note 4

J

1

1-1/2”

Indirect Water Heater

Supply or Return

----

K

1

3/4”

Indirect Water Heater Limit

----

1

Tappings on both end sections are identical - Recommend trim be installed in left end section or on same end as gas train.

2

This tapping is used for safety valve and surface blowoff (steam boilers) and safety relief valve (water boilers) on end not equipped with trim.

3

Temperature operating control location on tankless heater equipped boilers. Also alternate operating control location, tapped cover plate.

4

If using a float type LWCO, feeder or pump controller on a steam boiler that does not use quick connect hook up fittings, install between

tappings H and return B. Use opposite return B for system return connection. Water boilers using a probe LWCO must mount probe in

supply pipe above boiler without any stop valves.

SecTiON iii – iNSTALLATiON iNSTRUcTiONS (continued)