Table ii, Table iii – Burnham Series 5B User Manual

Page 31

31

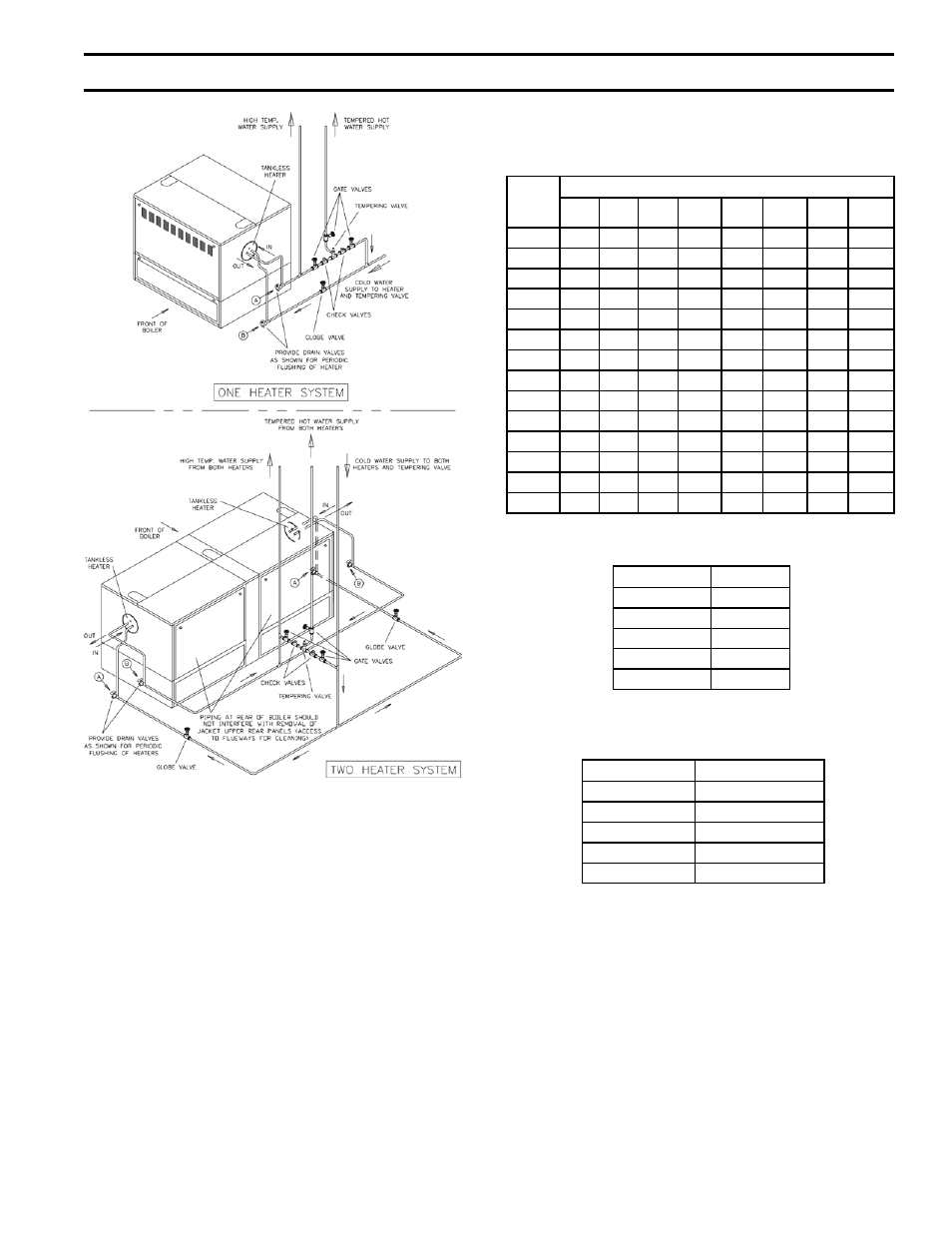

FIG. 30

RECOMMENDED PIPING TO

BUILT-IN TANKLESS HEATERS

TABLe i - NATURAL GAS

Maximum Capacity of Piping in Cubic Feet of Gas Per Hour

(Based on a Pressure Drop of 0.3” Water

and 0.6 Specific Gravity)

Pipe

Length

in Feet

NOMINAL IRON PIPE SIZE IPS INCHES

¾

1

1¼

1½

2

2½

3

4

10

278

520

1050

1600

3050

4800

8500

17500

20

190

350

730

1100

2100

3300

5900

12000

30

152

285

590

890

1650

2700

4700

9700

40

130

245

500

760

1450

2300

4100

8300

50

115

215

440

670

1270

2000

3600

7400

60

105

195

400

610

1150

1850

3250

6800

70

96

180

370

560

1050

1700

3000

6200

80

90

170

350

530

990

1600

2800

5800

90

84

160

320

490

930

1500

2600

5400

100

79

150

305

460

870

1400

2500

5100

125

72

130

275

410

78

1250

2200

4500

150

64

12

250

380

710

1130

2000

4100

175

59

110

225

350

650

1050

1850

3800

200

55

100

210

320

610

980

1700

3500

TABLe ii

Multipliers to be used with Table I when Pressure Drop is not 0.3”

Pressure Drop

Multiplier

0.1

.577

0.2

.815

0.5

1.29

1.0

1.83

0.3

1.00

TABLe iii

Multipliers to be used with Tables I and II for

Specific Gravity Other than 0.60

Specific Gravity

Correction Factors

.50

1.10

.55

1.04

.60

1.00

.65

.96

.70

.93

36.

OPEN GAS TRAIN CARTON(S)

CONNECT GAS TRAIN(S) TO ELBOW ON END OF

MANIFOLD(S) according to the Gas Trains on pages

86, 87, 88, 89, 90, 91 or 92.

PRESSURE TESTING of gas service piping must be

done before connecting to the boiler gas train. Test for

leaks by introducing, from an isolated source, air or

inert gas to the piping. Piping shall withstand 3 PSI

gage pressure for a period of not less than 10 minutes

without showing any drop in pressure.

37.

A DRIP LEG SHOULD BE PROVIDED IN THE

VERTICAL DROP TO EACH GAS TRAIN, see

Fig. 1. An additional Manual Shut-off valve and

SecTiON iii – iNSTALLATiON iNSTRUcTiONS (continued)

must be mounted so that cut off point is above

marking on Lowest Permissible Water Line Plate.

f. Install Pressure Safety Relief Valve, using fittings

furnished, into 1-1/2” pipe tapping in upper corner

of End Section. DO NOT INSTALL A SHUTOFF

VALVE BETWEEN SAFETY RELIEF VALVE

AND BOILER. Safety Relief Valve must be

installed in a Vertical Position with handle up.

g. Install Boiler Drain Valve into one of unused return

tappings that has been bushed to ¾”. Drain Valve

can also be installed in return piping, preferably

in leg of tee that is located in line with return

connection on Boiler.

35.

CONNECT PIPING TO BUILT-IN HEATER(S) IF

USED, see Fig. 30, top - left side of this page.